Chapter: Mechanical : Manufacturing Technology : Metal Joining Process

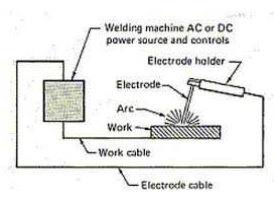

Arc welding

ARC WELDING

Uses an electric arc to coalesce metals

Arc welding is the most common method of welding metals

Electricity travels from electrode to base metal to ground

1.Arc welding Equipments

• A welding generator (D.C.) or Transformer (A.C.)

• Two cables- one for work and one for electrode

• Electrode holder

• Electrode

• Protective shield

• Gloves

• Wire brush

• Chipping hammer

• Goggles

2.Electrode

Electrode is a thin rod made up of same as that of parent material. Flux is coated over the electrode to avoid oxidation. It is mostly connected to the negative polarity.

Two Basic Types of AW Electrodes

Consumable – consumed during welding process Source of filler metal in arc welding

Nonconsumable – not consumed during welding process

Filler metal must be added separately

Consumable Electrodes

Forms of consumable electrodes

• Welding rods (a.k.a. sticks) are 9 to 18 inches and 3/8 inch or less in diameter and must be changed frequently

• Weld wire can be continuously fed from spools with long

lengths of wire, avoiding frequent interruptions

In both rod and wire forms, electrode is consumed by arc and added to weld joint as filler metal.

Nonconsumable Electrodes

Made of tungsten which resists melting

Gradually depleted during welding (vaporization is principal mechanism) Any filler metal must be supplied by a separate wire fed into weld pool

3.Flux

A substance that prevents formation of oxides and other contaminants in welding, or dissolves them and facilitates removal

Provides protective atmosphere for welding Stabilizes arc

Reduces spattering

4.STEPS FOLOWED IN ARC WELDING :

• Prepare the edges to be joined and maintain the proper position

• Open the acetylene valve and ignite the gas at tip of the torch

• Hold the torch at about 45deg to the work piece plane

• Inner flame near the work piece and filler rod at about 30 – 40 deg

• Touch filler rod at the joint and control the movement according to

the flow of the material

Advantages

Most efficient way to join metals

Lowest-cost joining method

Affords lighter weight through better utilization of materials

Joins all commercial metals

Provides design flexibility

Disadvantages

• Manually applied, therefore high labor cost.

• Need high energy causing danger

• Not convenient for disassembly.

• Defects are hard to detect at joints.

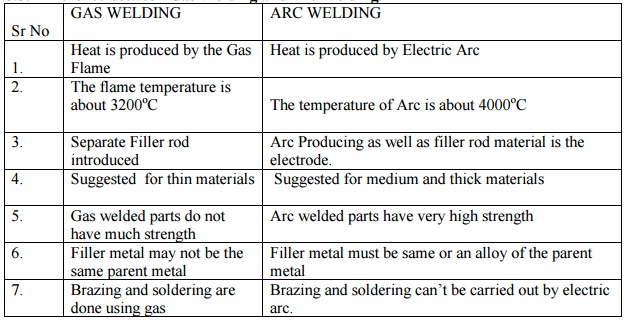

Difference between Gas Welding and Arc Welding

GAS WELDING

1. Heat is produced by the Gas Flame

2. The Flame temperature is about 3200oC

3. Separate Filler rod introduced

4. Suggested for thin materials

5. Gas welded parts do not have much strength

6. Filler metal may not be the same parent metal

7. Brazing and soldering are done using gas

ARC WELDING

1. Heat is produced by Electric Arc

2. The temperature of Arc is about 4000oC

3. Arc Producing as well as filler rod material is the electrode.

4. Suggested for medium and thick materials

5. Arc welded parts have very high strength

6. Filler metal must be same or an alloy of the parent metal

7. Brazing and soldering can’t be carried out by electric arc.

Related Topics