Chapter: Mechanical : Manufacturing Technology : Metal Joining Process

Important Questions and Answers: Metal Joining Process

METAL

JOINING PROCESS

1 List out any four arc welding

equipment.

Ans: The most commonly used equipments

for arc welding are as follows:

(a)

A.C or D.C. machine

(b)

Wire brush

(c)

Cables and connectors

(d)

Ear thing clamps

(e)

Chipping hammer

2 What are the special features of

friction welding?

Ans:

•

Friction welding is a solid state welding process

where coalescence is produced by the heat obtained from mechanically induced

sliding motion between rubbing surfaces.

• The work

parts are held together under pressure.

• Its

operating is simple.

• Power

required for the operation is low.

• It is

used for joining steels, super alloys, non-ferrous metals and combinations of

metals.

3.Define resistance welding process.

Ans: Resistance welding is a

process where coalescence is produced by the heat obtained from resistance

offered by the workpiece to the flow of electric current in a circuit of which

the workpiece is a part and by the application of pressure.

4.What is

the purpose of flux? (May 2008)

Ans: 1) It acts as shield to weld.

2)

To prevent atmospheric reaction of molten metal

with atmosphere.

5. How can

slag inclusions in welding be avoided?

Ans: Avoid multi layer welding

•

Reduce arc length

•

Increase electrode angle

•

Avoid using large electrode

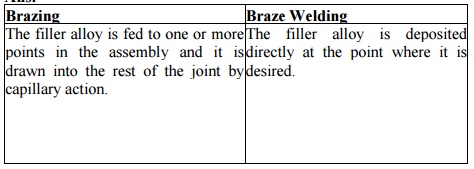

6. How does

brazing differ from braze welding?

Brazing

The

filler alloy is fed to one or more points

in the assembly

and it drawn into the rest of the

joint by capillary action.

Braze

Welding

The filler alloy is deposited

directly at the point where

it is desired.

7

Why flux is coated on filler rods?

Ans: The coating

improves penetration and surface finish.

• Suitable

coating will improve metal deposition rates.

8

What is the application of carburizing flame?

Ans:

•

Carburizing flame is generally used for: o Welding

of

low alloy

steel rods

o Non-ferrous metals o High carbon steel

9 What

are the diameter and length of the electrodes available in the market?

Ans: Standard length of electrodes are 250 mm, 300

mm and 450 mm.

•

Standard diameters of electrodes are 1.6,2 ,2.5,

3.2, 4,5,6,7,8, and 9 mm.

10.

Classify various ARC welding processes

(i)

Arc welding

•

Carbon arc

•

Metal arc

•

Metal inert gas

•

Tungsten inert gas

•

Plasma arc

•

Submerged arc

•

Electro-slag

11.

Classify various GAS welding processes

(ii) Gas

Welding

•

Oxy-acetylene

•

Air-acetylene

•

Oxy-hydrogen

12.Name the various methods of Resistance Welding

BUTT

Spot

Seam

Projection & Percussion.

13. What is ‘Brazing’

It is defined as the t3echnique of joining two

dissimilar or similar materials by addition of special filler material. Brazing

gives a much stronger joint than soldering but requires greater heat which

cannot be obtained from copper in soft soldering.

14.Mention the applications of friction welding.

Used in

refrigeration.

Used in

super alloys.

Making

simple forging.

Production

of taper and reamer drills

Production

of axle shafts , valves and gears.

15.Name the chemicals used in flux Manufacure.

1.Chlorides

2.Borax and boric acid. 3.Borates

4.Fluorides.

Related Topics