Chapter: Essential Microbiology: Industrial and Food Microbiology

Microorganisms in the production of biochemicals

Microorganisms

in the production of biochemicals

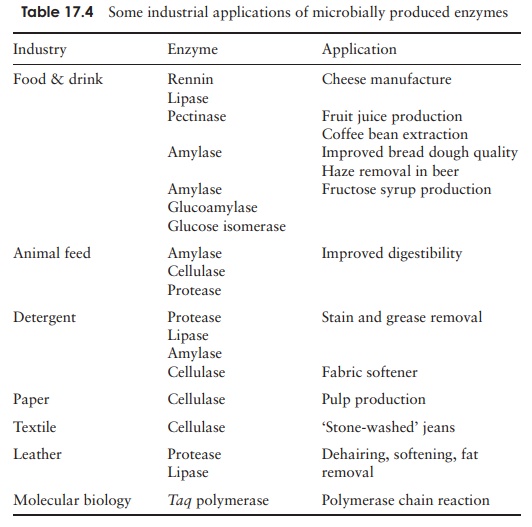

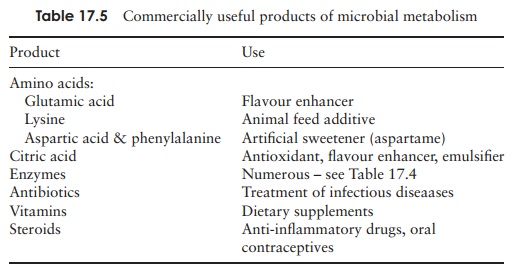

Many products of microbial metabolism find an

application in the food and other industries. These include amino acids,

steroids, enzymes and antibiotics (Table 17.4). Microbial growth conditions are

adjusted so that production of the metabolite in ques-tion takes place at an

optimal rate. Often an unnaturally high rate of production is achieved by the

use of a mutated or genetically engineered strain of microorganism, or by

manipulating culture conditions to favour excess metabolite production.

The development of a microbial means of producing

acetone was vital to the allied effort in the First World War. Acetone was a

crucial precursor in explosives manufacture and the demands of war soon

outstripped supply by traditional methods. The problem was solved when Chaim

Weismann isolated a strain of Clostridium

acetobutylicum that could ferment molasses to acetone and butanol (another

industrially useful product). Nowadays, acetone is made more cheaply from

petrochemicals.

Microbially produced amino acids are used in the food

industry, in medicine and as raw materials in the chemical industry. The one

produced in the greatest quantities by far is glutamic acid (in excess of half

a billion tonnes per year), with most of it ending up as the flavour enhancer

monosodium glutamate. The amino acids aspartic acid and phenylalanine are

components of the artificial sweetener aspartame and are also synthesised on a

large scale.

A number of organic acids are produced industrially

by microbial means, most no-tably citric acid, which has a wide range of

applications in the food and pharmaceutical industries. This is mostly produced

as a secondary metabolite by the large-scale culture of the mould Aspergillus niger.

Certain microorganisms serve as a ready source of vitamins. In many cases these can be

synthesised less expensively by chemical means; however, riboflavin (by the

mould Ashbya gossypii) and vitamin B12 (by the

bacteria Propionibacterium shermanii

and Pseudomonas denitrificans) are

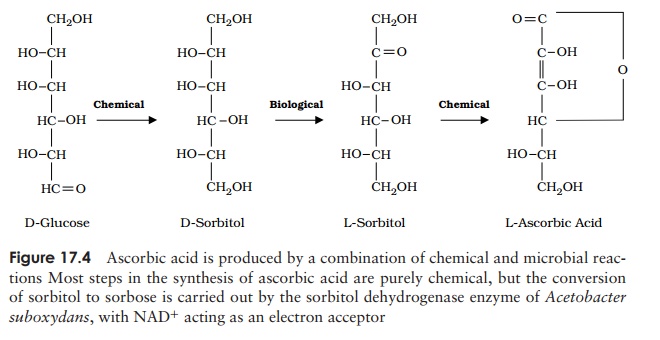

produced by large-scale microbial fermentation. Microorganisms play a partial

role in the production of ascorbic acid (vitamin C). Initially, glucose is

reduced chemically to sorbitol, which is then oxidised by a strain of Acetobacter suboxydans to the hexose

sorbose. Chemical modifications convert this toascorbic acid (Figure 17.4).

Enzymes of fungal and bacterial origin have been

utilised for many centuries in a variety of processes. It is now possible to

isolate and purify the enzymes needed for a specific process and the worldwide

market is cur-rently worth around a billion pounds. The most useful industrial

enzymes include proteases, amylases, lipases

Syrups and modified starches are used in a wide range

of foodstuffs, including soft drinks, confectionery and ice cream, as well as

having a wealth of other applications. Different enzymes or combinations of

enzymes are used to produce the desired consis-tencies and physical properties.

High fructose corn syrup (HFCS) is a sweetener used in a multitude of food

products. It is some 75 per cent sweeter than sucrose and has sev-eral other

advantages. HFCS is a mixture of fructose, dextrose (a form of glucose) and

disaccharides, and is produced by the action of a series of three enzymes on

the starch (amylose and amylopectin) of corn (maize). Alpha amylase hydrolyses

the internal α-1,

4-glycosidic bonds of starch, but is not able to degrade ends of the chain. The

resulting di- and oligosaccharides are broken down to the monomer glucose by

the action of glucoamylase, then finally glucose isomerase converts some of the

glucose to its isomer, fructose.

Enzymes have been added to cleaning products such as washing powders, carpet shampoos and stain removers since the 1960s, and this remains one of the principal

Proteases are the most widely used

enzymes in this context; working in combination with a surfactant, they

hydrolyse protein-based stains such as blood, sweat and various foods. Greasy

and oily stains present a different challenge, made all the more difficult by

the move towards lower washing temperatures. The inclusion of lipases aids the removal of stains such

as butter, salad dressing and lipstick, while amylases deal with starch-based stains such as cereal or custard.

The food and detergent industries between them account for around 80 per cent

of all enzyme usage.

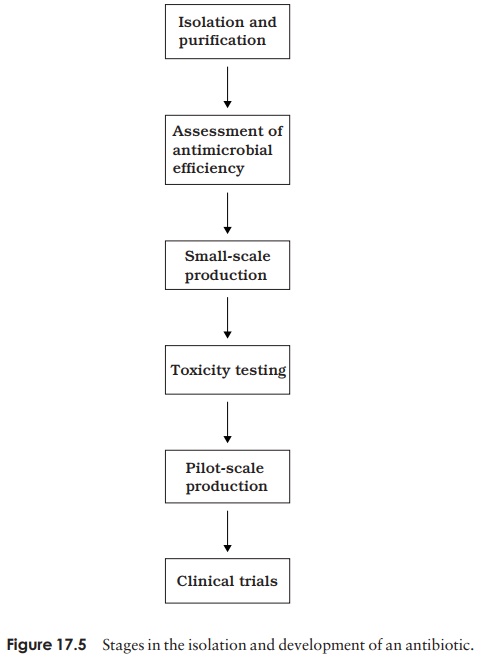

We have already seen that antibiotics are now

produced on a huge scale worldwide. Figure 17.5 outlines the stages in the

isolation, development and production of an antibiotic.

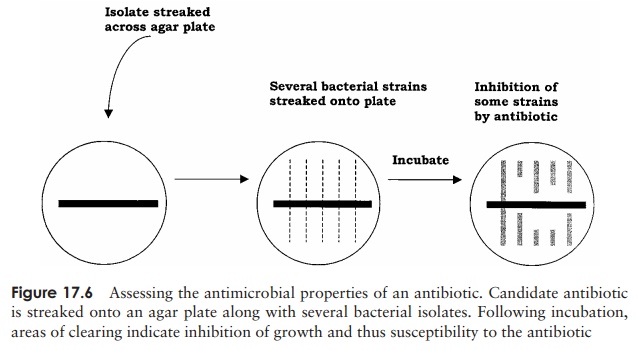

Isolating an antibiotic from a natural source is not

all that difficult, but finding a new one that is therapeutically useful is

another matter. Initially, the antimicrobial properties of a new isolate are

assessed by streaking it across an agar plate, then inoculating a range

of bacteria at right angles (Figure 17.6). As the

antibiotic diffuses through the agar, it will inhibit growth of any susceptible

species. Isolates that still show potential are then grown up in a laboratory

scale fermenter; it is essential for commercial culture that the

antibiotic-producing organism can be cultured in this way.

Before committing to large-scale production,

exhaustive further tests must be carried out on two fronts: to ascertain the

potency of the preparation and the breadth of its antimicrobial spectrum, and

to determine its therapeutic index by

carrying out toxicity testing on animals. The final stages of development

involve pilot-scale production, followed by clinical trials on human

volunteers.

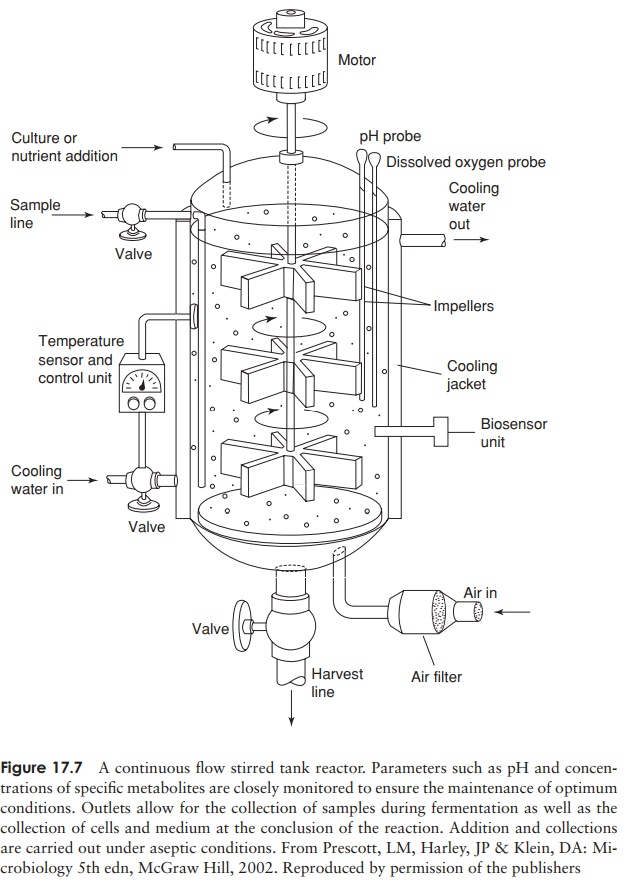

When an antibiotic or any other fermentation product

finally goes into production, it is cultured in huge stirred fermenters or bioreactors, which may be as large as

200 000 litres. A typical stirred fermenter has impellers for mixing the

culture, an air line for aeration and microprocessor-controlled probes for the

continuous monitoring and regulation of temperature, pH and oxygen content

(Figure 17.7). Cultures with a high protein content may also have an

antifoaming agent added. The process of scale-up

is a complex operation, and not simply a matter of growing the microorganism in

question in ever-larger vessels. Factors such as temperature, pH, aeration,

must all be considered at the level of the individual cell if scale-up is to be

successful. Fermenters are usually made from stainless steel, which can

withstand heat sterilisation; the economic consequences of microbial

contamination when working on such a large scale can be immense.

Related Topics