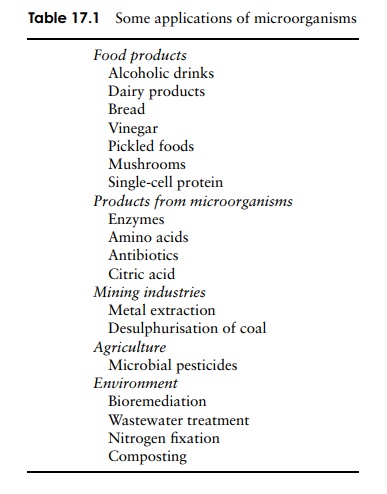

Chapter: Essential Microbiology: Industrial and Food Microbiology

Microorganisms and food

Microorganisms and food

To the general public, the association of microorganisms and food

conjures up negative images of rotten fruit or food poisoning. On reflection,

many people may remember that yeast is involved in bread and beer production,

but how many realise that microor-ganisms play a part in the manufacture of soy

sauce, pepperoni and even chocolate? In the following pages, we shall look at

the contribution of microorganisms to the contents of our shopping baskets

before considering one of the negative associations referred to above, the

microbial spoilage of food.

The production of foodstuffs as a result of microbial fermentation

reactions pre-dates recorded history. The accidental discovery that such foods

were less susceptible to spoilage than fresh foods must have made them an

attractive proposition to people in those far-off days. Of course, until

relatively recent times, nothing was known of the part played by

microorganisms, so the production of beer, cheese and vinegar would not have

been the carefully controlled processes that are used today. Indeed, it was

only with the development of isolation techniques towards the end of the

nineteenth century, that it became possible to use pure cultures in food

production for the first time. The fermentation of foodstuffs, hitherto an art,

became a science.

Alcoholic fermentations

There is evidence that alcoholic drinks, including

beer and wine, were being produced thousands of years be-fore the Christian

era, making them among the earliest known examples of the exploitation of

microorganisms by humans. Ethanol results from the fermentation pro-cess,

because the conversion of sugar to carbon dioxide and water is incomplete:

C6H12O6−−−−−−−→ 2CH3CH2OH + 2CO2

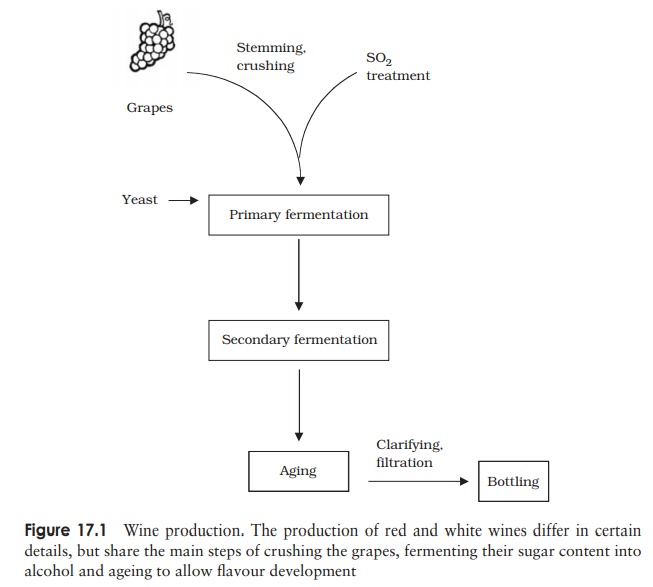

Although, in principle, wine can be made from almost

any fruit juice with a high sugar content, the vast major-ity of commercially

produced wines derive from the fer-mentation of the sugar present in grapes

(Figure 17.1). Such fermentation reactions may be initiated by yeasts naturally

found on the grape skin; however the results of such fermentations are erratic

and may be unpalatable. In commercial winemaking the must (juice) resulting from the crushed grapes is treated with

sulphur dioxide to kill off the natural microflora, and then inoculated with

the yeast Saccharomyces cerevisiae,

variety ellipsoideus. Specially

developed strains are

used, which produce a higher percentage of alcohol

(ethanol) than naturally occurring yeasts. Fermentation proceeds for a few days

at a temperature of 22–27 ◦ C for red

wines (lower for whites), after which the wine is separated from the skins by

pressing. This is followed by ageing in oak barrels, a process that may last

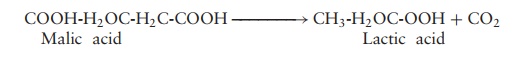

several months, and during which the flavour develops. Malolactic fermentation is a secondary fermentation carried out on

certain types of wine. Malic acid, which has a sharp taste, is converted to the

milder lactic acid, imparting smoothness to the wine.

COOH-H2OC-H2C-COOH (Malic acid) −−−−−−−→ CH3-H2OC-OOH (Lactic acid) + CO2

A secondary product of malolactic fermentation is

di-acetyl, which imparts a ‘buttery’ flavour to the wine. Spir-its such as

brandy and rum result from the products of a fermentation process being

concentrated by distillation. This

gives a much higher alcohol content than that of wines.

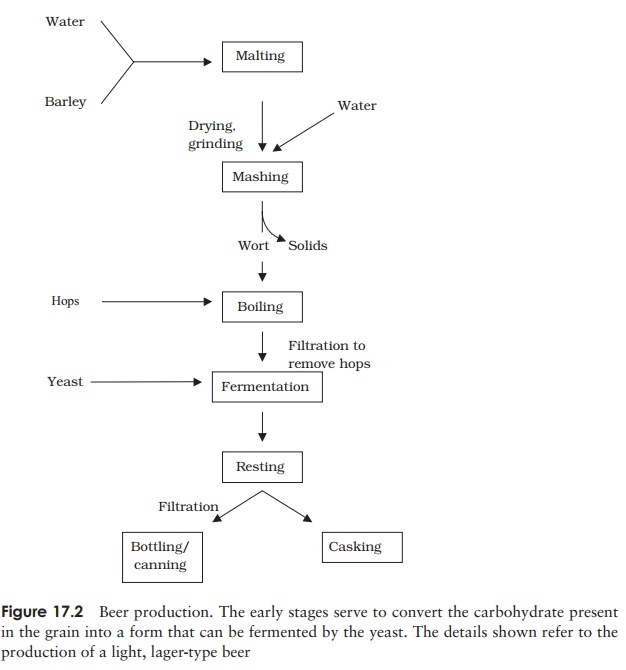

Beer is produced by the fermentation of barley grain.

The procedure varies according to the type of beer, but follows a series of

clearly defined steps (Figure 17.2). Grain, unlike grapes, contains no sugar to

serve as a sub-strate for the yeast, so before fermentation can begin, it is

soaked in water and allowed to germinate. This stim-ulates the production of

the enzymes necessary for the conversion of starch to maltose (‘malting’). An additional source of

starch may be introduced during the next stage, mashing, in which the grains are ground up in warm wa-ter, and

further digestion takes place. The liquid phase or wort is drained off and hops are added. They im-part flavour and

colour to the finished product and also possess antimicrobial properties,

thereby helping to prevent contamination. The mixture is boiled, inactivating

the enzymes, precipitating proteins and killing off any microor-ganisms. In the

next stage, the wort is filtered and transferred to the fermentation vessel where

yeast is introduced.

Two species of yeast are commonly used in the brewing

process, both belonging to the genus Saccharomyces.

S.cerevisiae is mainly used in the

production of darker beerssuch as traditional English ales and stouts, whereas S.carlsbergensis (no prizes for guessing

where this one wasdeveloped!) gives lighter coloured, less cloudy, lager-type

beers. Cells of S. cerevisiae are

carried to the surface of the fermentation by carbon dioxide bubbles (top

fermenters), while S. carlsbergensis

cells form a sediment at the bottom (bottom fermenters). ‘Spent’ yeast may be

dried, and used as an animal food supplement.

Fermentation takes about a week to complete, at a

temperature appropriate for each type of yeast (S. carlsbergensis prefers somewhat lower temperatures than S. cerevisiae). Following fermentation,

the beer is allowed to age or ‘rest’ for some months in the cold. Beers

destined for canning or bottling are filtered to remove remaining

microorganisms.

Beers typically have an alcohol content of around 4

per cent. Small amounts of other secondary products such as amyl alcohol and

acetic acid are also produced, and con-tribute to the beer’s flavour. ‘Light’

or low-carbohydrate beers are produced by reducing the levels of complex

carbohydrates. The yeast do not possess the enzymes necessary to cope with

these branched molecules, so a supplement of debranching enzymes may be added

to aid their breakdown.

Dairy products

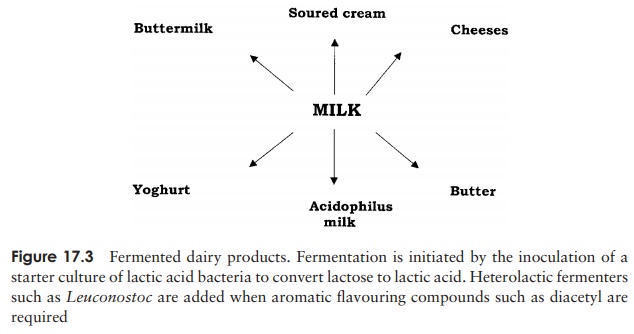

Milk can be fermented to produce a variety of

products, including butter, yoghurt and cheese (Figure 17.3). In each case,

acid produced by the fermentation process causes coagulation or curdling of the

milk proteins.

In cheese-making, this coagulation is effected by the

addition of the protease rennin, or

by the action of lac-tic acid bacteria (especially Streptococcus lactis and S.

cremoris). Coagulation allows the separation of thesemisolid curd from the liquid whey. The subsequent steps in the

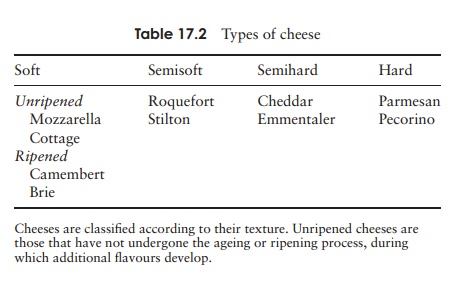

cheese-making process depend on the spe-cific type of cheese (Table 17.2).

Following separation, the curd of most cheeses is pressed and shaped, removing

excess liquid and firming the texture. During the ripening process, salt is

often added, and flavour develops due to continuing microbial action on the

protein and fat components of the cheese. In some cases, a fresh inoculation of

microorganisms is made at this point, such as the addition of Penicillium spores to Camembert and

Brie. The length of the ripening period varies from a month to more than a year

according to type, with the harder cheeses requiring the longer periods.

Yoghurt is another milk derivative. Thickened milk is

exposed to the action of two bacteria, Streptococcus

thermophilus and Lactobacillus

bulgaricus, both of which fer-ment lactose present in milk into lactic

acid. In addition, L. bulgaricus

contributes aromatics responsible for imparting flavour to the yoghurt.

Other dairy products, such as soured cream and

buttermilk, are also produced by means of the fermentative properties of

species of streptococci and lactobacilli.

Bread

The biological agent responsible for bread production

is yeast. In fact baker’s yeast and brewer’s yeast are just different strains

of the same species, Saccharomyces

cerevisiae. In breadmaking, aerobic, rather than anaerobic conditions are

favoured, so sugar present in the dough is converted all the way to carbon

dioxide rather than to alcohol. It is this

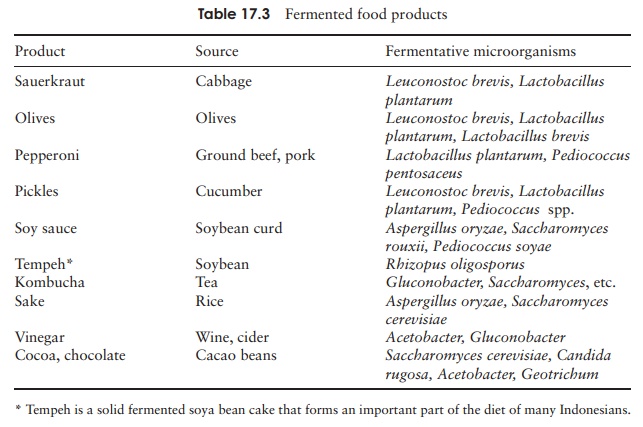

Many other popular foodstuffs are the result of

microbial fermentation processes (see Table 17.3). These include vinegar, soy

sauce and sauerkraut. Silage is

animal fodder made from the fermentation of grass and other plant material by

the action of lactic acid bacteria.

Related Topics