Terminology, Types of separation or concentration of an ore - Metallurgy | 10th Science : Chapter 8 : Periodic Classification of Elements

Chapter: 10th Science : Chapter 8 : Periodic Classification of Elements

Metallurgy

METALLURGY

Human life is associated

with various metals. We use metals in our day to day activities. It is the

utmost need to have some metals like sodium, potassium, calcium, iron, etc. in

the human body. Deficiency of these metals affects the metabolic activities

thereby causing diseases. So, metals play a vital role in our life. In this

section, let us discuss how metals are obtained from various sources by the

process of metallurgy.

Metallurgy is a science of extracting metals from their ores and

modifying the metals into alloys for various uses, based on their physical and

chemical properties and their structural arrangement of atoms. A metallurgical process

involve three main steps as follows:

(i) Concentration or Separation

of the ore: It is the process of removal of impuries from the ore.

(ii) Production of the

metal: It

is the convertion of the ore into metal.

(iii) Refining of the

metal: It

is the process of purification of the metal.

![]()

![]()

1. Terminology in metallurgy

Minerals: A mineral may be a

single compound or a complex mixture of various compounds of metals

found in the Earth.

Ore: The mineral from which a

metal can be readily and economically extracted on a large scale is said

to be an ore.

For example: Clay (Al2O

3. 2 SiO 2. 2 H2O) and

bauxite (Al2O3 .2 H2O) are the two minerals of

aluminium, but aluminium can be profitably extracted only from bauxite. Hence,

bauxite is an ore of aluminium and clay is its mineral.

Mining: The process of

extracting the ores from the Earth's crust is called mining.

Gangue or Matrix: The rocky impurity associated

with an ore is called gangue or matrix.

Flux: It is the substance

added to the ore to reduce the fusion temperature and to remove the

impurities. E.g. Calcium oxide (basic), Silica (acidic). If the gangue is

acidic, then basic flux is added and vice versa.

Slag: It is the fusible

product formed when a flux reacts with a gangue during the extraction of

metals.

Flux + Gangue → Slag

Smelting: Smelting is the process

of reducing the roasted metallic oxide from the metal in its molten

condition. In this process, impurities are removed as slag by the addition of

flux.

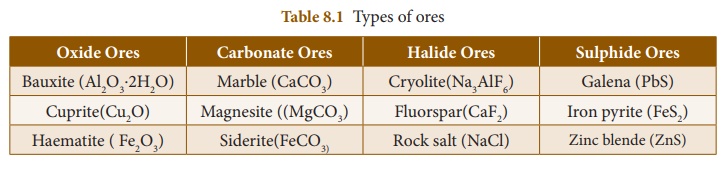

2. Types of separation or concentration of an ore

There are four major

types of separation of ores based on the nature of the ore. The different kinds

of ores of metals are given in Table 8.1

Concentration of the

crushed ore is done mainly by the following methods: -

(i) Hydraulic (Gravity Separation) method

Principle:

The difference in the

densities or specific gravities of the ore and the gangue is the main principle

behind this method. Oxide ores are purified by this method. e.g., Haematite

Fe2O3 the ore of iron.

Method:

The ore is poured over a

sloping,vibrating corrugated table with grooves and a jet of water is allowed

to flow over it. The denser ore particles settle down in the grooves and

lighter gangue particles are washed down by water.

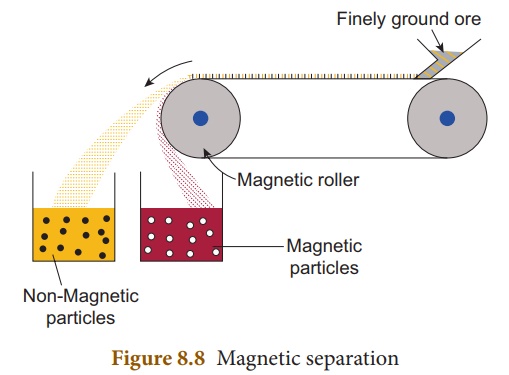

(ii) Magnetic separation method

Principle:

The magnetic properties

of the ores form the basis of separation. When either the ore or the gangue is

magnetic, this method is employed. e.g., Tinstone SnO2, the ore of tin.

Method: The crushed ore is

placed over a conveyer belt which rotates around two metal wheels, one of which

is magnetic. The magnetic particles are attracted to the magnetic wheel and

fall separately apart from the non- magnetic particles.

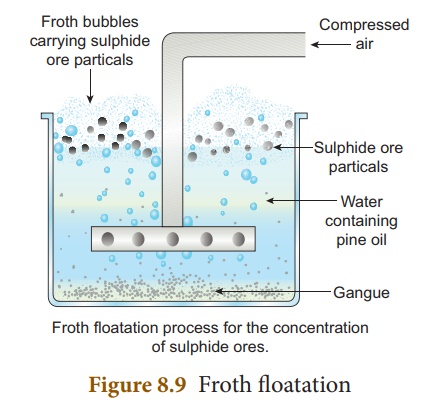

(iii) Froth floatation

Principle:

This process depends on

the preferential wettability of the ore with oil (pine oil) and the gangue

particles by water. Lighter ores, such as sulphide ores, are concentrated by

this method. e.g., Zinc blende (ZnS).

Method:

The crushed ore is taken

in a large tank containing oil and water and agitated with a current of

compressed air. The ore is wetted by the oil and gets separated from the gangue

in the form of froth. Since the ore is lighter, it comes on the surface with

the froth and the impurities are left behind. e.g., Zinc blende (ZnS).

(iv) Chemical method or Leaching

This method is employed

when the ore is in a very pure form.

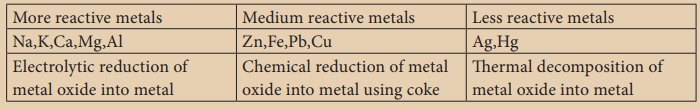

Extraction of metal from metal oxide can be categorized into three types.

The ore is treated with

a suitable reagent such that the ore is soluble in it but the impurities are

not. The impurities are removed by filtration. The solution of the ore, ie.,

the filtrate is treated with a suitable reagent which precipitates the ore.

E.g. Bauxite Al2O3.2H2O, the ore of aluminium.

Related Topics