Occurrence of Ores, Physical and Chemical Properties, Uses - Extractive Metallurgy of Copper | 10th Science : Chapter 8 : Periodic Classification of Elements

Chapter: 10th Science : Chapter 8 : Periodic Classification of Elements

Extractive Metallurgy of Copper

EXTRACTIVE METALLURGY OF

COPPER

Occurrence:

It was named as cuprum

by the Romans because they got it from the Island of Cyprus. Copper is found in

the native state as well as combined state.

Ores of copper Formula

Copper pyrites CuFeS2

Cuprite or ruby copper Cu2O

Copper glance Cu2S

The chief ore of copper

is copper pyrite. It yields nearly 76% of the world production of copper.

Extraction of copper from copper pyrites involves the following steps

i. Concentration of ore: The ore is crushed and the concentrated

by froth floatation process.

ii. Roasting: The concentrated ore is

roasted in excess of air. During the process of roasting, the moisture

and volatile impurities are removed. Sulphur, phosphorus, arsenic and antimony

are removed as oxides. Copper pyrite is partly converted into sulphides of

copper and iron.

2CuFeS2 + O2 → Cu2S

+ 2 FeS + SO2 ↑

iii. Smelting: The roasted ore is mixed with powdered

coke and sand and is heated in a blast furnace to obtain matte (Cu2S

+ FeS) and slag. The slag is removed as waste.

iv. Bessemerisation: The molten matte is transferred to

Bessemer converter in order to obtain blister copper. Ferrous sulphide from

matte is oxidized to ferrous oxide, which is removed as slag using silica.

2 FeS + 3 O2 → 2 FeO + 2

SO2 ↑

FeO + SiO2 → FeSiO3

(slag) (Iron

silicate)

2 Cu2S + 3O2

→ 2 Cu2O + 2 SO2 ↑

2 Cu2O + Cu2S

→ 6 Cu + SO2↑ (Blister

copper)

v. Refining: Blister copper contains

98% of pure copper and 2% of impurities and is purified by electrolytic

refining. This method is used to get metal of a high degree of purity. For

electrolytic refining of copper, we use:

Cathode: A thin plate of pure

copper metal.

Anode: A block of impure

copper metal.

Electrolyte: Copper sulphate

solution acidified with sulphuric acid.

When electric current is

passed through the electrolytic solution, pure copper gets deposited at the

cathode and the impurities settle at the bottom of the anode in the form of

sludge called anode mud.

Physical Properties of Copper

Copper is a reddish

brown metal, with high lustre, high density and high melting point (1356°C).

Chemical Properties of Copper

i. Action of Air and Moisture: Copper gets covered

with a green layer of basic copper carbonate in the presence of CO2

and moisture.

2 Cu + O2 +

CO2 + H2O → CuCO3.Cu(OH)2

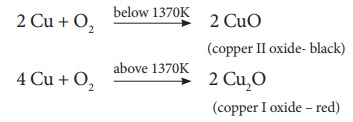

ii. Action of Heat: On

heating at different temperatures in the presence of oxygen, copper forms two

types of oxides CuO, Cu2O.

iii. Action of Acids:

a) With dilute HCl and

dilute H2SO4:

Dilute acids such as HCl

and H2SO4 have no action on these metals in the absence

of air. Copper dissolves in these acids in the presence of air.

2 Cu + 4 HCl + O2

(air) →2 CuCl2 + 2 H2O

b) With dil. HNO3:

Copper reacts with dil.

HNO3 with the liberation of Nitric Oxide gas.

3 Cu + 8 HNO3

→ Cu(NO3)2 + 2 NO ↑ + 2H2O

Cu + 2 H2SO4

→ CuSO4 + SO2 ↑ + 2 H2O

iv) Action of Chlorine:

Chlorine reacts with

copper, resulting in the formation of copper(II) chloride.

Cu + Cl2 ![]() CuCl2

CuCl2

v) Action of Alkalis:

Copper is not attacked

by alkalis.

Uses of Copper:

i.

It is extensively used in manufacturing electric cables and other

electric appliances.

ii.

It is used for making utensils, containers, calorimeters and

coins,

iii.

It is used in electroplating.

iv.

It is alloyed with gold and silver for making coins and jewels

Related Topics