Occurrence of Ores, Physical and Chemical Properties, Uses - Extractive Metallurgy of Iron | 10th Science : Chapter 8 : Periodic Classification of Elements

Chapter: 10th Science : Chapter 8 : Periodic Classification of Elements

Extractive Metallurgy of Iron

EXTRACTIVE METALLURGY OF

IRON

Occurrence:

Iron is the second most

abundant metal available next to aluminium. It occurs in nature as oxides,

sulphides and carbonates. The ores of iron are as follows:

Ores of iron Formula

Haematite Fe2O3

Magnetite Fe3O4

Iron pyrite FeS2

Iron is chiefly

extracted from haematite ore (Fe2O3)

i. Concentration by Gravity Separation: The powdered ore

is washed with a steam of water. As a result, the lighter sand particles and

other impurities are washed away and the heavier ore particles settle down.

ii. Roasting and

Calcination: The concentrated ore is strongly heated in a limited supply

of air in a reverberatory furnace. As a result, moisture is driven out and

sulphur, arsenic and phosphorus impurities are oxidized off.

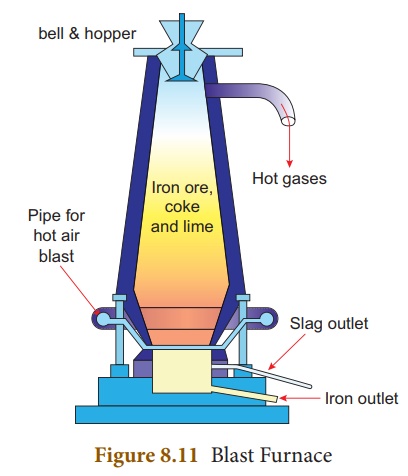

iii. Smelting (in a Blast

Furnace): The

charge consisting of roasted ore, coke and limestone in the ratio 8:4:1 is

smelted in a blast furnace by introducing it through the cup and cone

arrangement at the top. There are three important regions in the furnace.

(a) The Lower Region

(Combustion Zone)-The temperature is at 1500°C. In this region, coke burns with

oxygen to form CO2 when the charge comes in contact with a hot blast

of air.

It is an exothermic

reaction since heat is liberated.

(b) The Middle Region

(Fusion Zone) – The temperature prevails at 1000°C. In this region, CO2

is reduced to CO.

Limestone decomposes to

calcium oxide and CO2.

These two reactions are

endothermic due to absorption of heat. Calcium oxide combines with silica to

form calcium silicate slag.

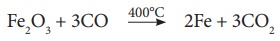

(c) The Upper Region

(Reduction Zone)- The temperature prevails at 400°C . In this region carbon

monoxide reduces ferric oxide to form a fairly pure spongy iron.

The molten iron is

collected at the bottom of the furnace after removing the slag.

The iron thus formed is

called pig iron. It is remelted and cast into different moulds. This iron is

called cast iron.

Physical properties:

·

It is a lustrous metal, greyish white in colour.

·

It has high tensility, malleability and ductility.

·

It can be magnetized.

Chemical properties:

i. Reaction with air or oxygen: Only on heating in air, iron forms

magnetic oxide.

3Fe + 2 O2 → Fe3O4 (black)

ii. Reaction with moist air: When iron is exposed to moist air, it

forms a layer of brown hydrated ferric oxide on its surface. This compound is

known as rust and the phenomenon of formation of rust is known as rusting.

4 Fe+ 3 O2 +

x H2O →2 Fe2O3 . xH2O(rust)

iii. Reaction with steam: When steam is passed over red hot iron,

magnetic oxide is formed.

3Fe + 4 H2O (steam) → Fe3O4

+ 4 H2 ↑

iv. Reaction with chlorine: Iron combines with chlorine to form

ferric chloride.

2Fe + 3Cl2 → 2FeCl3

(ferric chloride)

v. Reaction with acids: With dilute HCl and dilute H2SO4

it liberates H2 gas.

Fe + 2HCl → FeCl2

+ H2 ↑

Fe + H2SO4

→ FeSO4 + H2 ↑

With dilute HNO3

in cold condition it gives ferrous nitrate.

4 Fe + 10 HNO3

→ 4 Fe(NO3)2 + NH4NO3 + 3 H2O

With con. H2SO4

it forms ferric sulphate.

2 Fe + 6 H2SO4

→ Fe2(SO4)3 + 3 SO2 + 6 H2O

When iron is dipped in

con. HNO3 it becomes chemically passive or inert due to the

formation of a layer of iron oxide (Fe3O4) on its

surface.

Uses of iron

Pig iron (Iron with 2-4.5% of

carbon): It is used in making pipes, stoves, radiators, railings,

manhole covers and drain pipes.

Steel (Iron with < 0.25% of

carbon): It is used in the construction of buildings, machinery,

transmission cables and T.V towers and in making alloys.

Wrought iron (Iron with 0.25-2% of

wraught carbon): It is used in making springs, anchors and

electromagnets.

Related Topics