Book Back and Important Questions Answers | Chemistry - Metallurgy: Answer the following questions | 12th Chemistry : UNIT 1 : Metallurgy

Chapter: 12th Chemistry : UNIT 1 : Metallurgy

Metallurgy: Answer the following questions

Chemistry : Metallurgy

Answer the following questions:

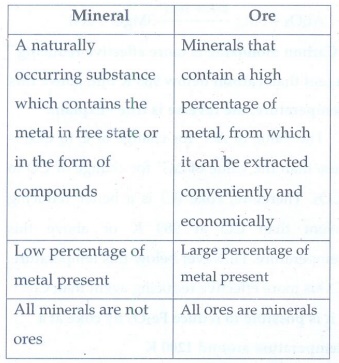

1. What are the differences between minerals and ores?

Mineral

•

A naturally occurring substance which contains the metal in free state or in

the form of compounds

•

Low percentage of metal present

•

All minerals are not ores

Ore

•

Minerals that contain a high percentage of metal, from which it can be

extracted conveniently and economically

•

Large percentage of metal present

•

All ores are minerals

2. What are the various steps involved in extraction of pure metals from their ores?

(i)

Concentration of the ore

(ii)

Extraction of crude metal

(iii)

Refining of crude metal

3. What is the role of Limestone in the extraction of Iron from its oxide Fe2O3 ?

The

silica gangue present in the iron ore is acidic in nature. Silica removed by

using basic flux, limestone (CaO). The limestone combines with silica gangue to

form calcium silicate (slag). The slag was removed.

CaCO3

___Δ__→ CaO + CO2

CaO(s) [Flux]

+ SiO2(S)

[Gangue] → CaSiO3(S)

[Slag]

Flux + Gangue → Slag

4. Which type of ores can be concentrated by froth floatation method? Give two examples for such ores.

Sulphide

ores can be concentrated by froth flotation method.

Example: Zinc

blende (ZnS), Silver glance (Ag2S)

5. Out of coke and CO, which is better reducing agent for the reduction of ZnO? Why?

Coke

(C) is a better reducing agent for the reduction of ZnO. From the Ellingham

diagram, the free energy for the formation of CO from C is lower at above 1120

K while that of CO2 from carbon is lower at above 1320 K than free

energy of formation of ZnO. However, the free energy of formation of CO2 from

CO is always higher than that of ZnO.

6. Describe a method for refining nickel.

The

impure nickel is heated in a stream of carbon monoxide at around 350 K. The

nickel reacts with the CO to form a highly volatile nickel tetracarbonyl. The

solid impurities are left behind.

Ni

(s) + 4 CO (g) → Ni(CO)4 (g)

The

nickel tetracarbonyl heated around 460 K, the complex decomposes to give pure

nickel.

Ni(CO)4 (g) → Ni (s) + 4 CO (g)

7. Explain zone refining process with an example using the Ellingham diagram given below.

Zone refining process:

i)

This method is based on the principle of fractional crystallisation. When an

impure metal is melted and allowed to solidify, the impurities are more soluble

in the melt than in the solid state metal.

ii)

The impure metal is taken in the form of a rod. One end of the rod is heated

using a mobile induction heater which results in melting of the metal on that

portion of the rod.

iii)

When the heater is slowly moved to the other end, the pure metal crystallises

while the impurities will move on to the adjacent molten zone formed. As the

heater moves further away, the impurities also moves along with it.

iv)

The process is repeated several times to achieve the pure element.

v)

This process is carried out in an inert gas atmosphere to prevent the oxidation

of metals.

Example:

Elements

such as germanium (Ge), silicon (Si) and galium (Ga) that are used as

semiconductor are refined using this process.

8. (A) Predict the conditions under which

(i) Aluminium might be expected to reduce magnesia.

In

the Ellingham diagram, above 1623 K, the ∆G° value for Al2O3

is more negative than that of MgO. Thus ∆G° of the reaction is negative.

Therefore

above 1623 K, Al can reduce MgO to Mg.

3MgO + 2Al ___1623 K__→ Al2O3

+ 3Mg

(ii) Magnesium could reduce alumina.

In

the Ellingham diagram, below 1623 K the ∆G° value of Al2O3,

is less negative than that of MgO. Thus, ∆G°of the reaction is negative.

Therefore, below 1623 K, Mg can reduce Al2O3 to Al.

Al2O3 + 3Mg ___below 1623__→ 3MgO +

2Al

(B) Carbon monoxide is more effective reducing agent than carbon below 983K but, above this temperature, the reverse is true –Explain.

The

value of ∆G° for change of C to CO2 is less than the value of ∆G°

for change of CO to CO2. Therefore, coke (C) is a better reducing

agent than CO at 983 K or above this temperature. However below this

temperature, CO is more effective reducing agent than C.

(C) it is possible to reduce Fe2 O3 by coke at a temperature around 1200K

Yes,

it is possible to reduce Fe2O3 by coke at a temperature

around 1200K . Ellingham diagram for the formation of FeO and CO intersects

around 1000 K. Below this temperature, the carbon line lies above the iron line

which indicates that FeO is more stable and the reduction is thermodynamically

not feasible. Around 1200 K carbon line lies below the iron line and hence,

coke can be used as reducing agent.

Fe2O3

+ C → 2Fe + 3CO

9. Give the uses of zinc.

• Metallic zinc is used in

galvanising metals.

• It is used to produce

die-castings in the automobile, electrical and hardware industries.

• Zinc oxide is used in the

manufacture of many products such as paints, rubber, cosmetics,

pharmaceuticals, plastics, inks, batteries, textiles and electrical equipment.

• Zinc sulphide is used in making

luminous paints, fluorescent lights and X-ray screens.

• Brass an alloy of zinc is used in

water valves and communication equipment as it is highly resistant to

corrosion.

10. Explain the electrometallurgy of aluminium.

Hall-Heroult

process:

Cathode: Iron

tank lined with carbon

Anode: The

carbon blocks immersed in the electrolyte

A

20% solution of alumina, obtained from the bauxite ore is mixed with molten

cyrolite and is taken in the electrolysis chamber.

About

10% calcium chloride is also added to the solution, which lowers the melting

point of the mixture.

The

fused mixture is maintained at a temperature of above 1270 K.

Ionisation

of alumina

Al2O3

→ 2Al3+ + 3O2−

Reaction

at cathode

Al3+

(melt) + 3e− → Al (1)

Reaction

at anode

2O2−

(melt) → O2 + 4e−

Carbon

anode consumed slowly.

C(s)

+ O2− (melt) → CO + 2e−

C(s)

+ 2O 2− (melt) → CO2 + 4e−

The

pure aluminium is formed at the cathode and settles at the bottom. The net

electrolysis reaction is

4Al3+

(melt) + 6O2(melt) + 3C(s) → 4Al(ℓ)

+ 3CO2(g)

11. Explain the following terms with suitable examples.

(i) Gangue (ii) slag

Gangue:

The

ores are associated with nonmetallic impurities, rocky materials and siliceous

matter which are collectively known as gangue.

Example:

The

silica gangue present in the iron ore

Slag:

When

gangue present in the roasted or calcined ore combined with the flux forms a

fusible material called slag.

Example:

Silica

gangue in the iron ore removed by using limestone (CaO). The slag was removed.

CaO(s) [Flux]

+ SiO2(s) [Gangue]

→ CaSiO3(s) [Slag]

Flux + Gangue → Slag

12. Give the basic requirement for vapour phase refining.

• The metal is treated with a

suitable reagent it should form a volatile compound with the metal.

• The volatile compound is easily

decomposed to give the pure metal.

13. Describe the role of the following in the process mentioned.

(i) Silica in the extraction of copper.

(ii) Cryolite in the extraction of aluminium.

(iii) Iodine in the refining of Zirconium.

(iv) Sodium cyanide in froth floatation.

(i) Silica in the

extraction of copper.

Silica

is used as flux material in the extraction of copper.

The

concentrated ore is heated with an acidic flux silica. The ferrous oxide formed

due to melting is basic in nature and it combines with silica to form ferrous

silicate (slag).

FeO

+ SiO2 → FeSiO3

(ii) Cryolite in

the extraction of aluminium.

(a)

The melting point of alumina is very high.

Hence

it is mixed with cryolite (Na3AlF6) which lowers its

melting point

(b)

Cryolite increase the electrical conductivity of alumina.

(c)

The function of cryolite is to lower the fusion temperature.

(iii) Iodine in the

refining of Zirconium.

The

impure zirconium metal is heated with iodine at a temperature of 550 K to form

the volatile zirconium tetra-iodide. The impurities are not reacting with

iodine. The volatile tetraiodide vapour is passed over a tungsten filament at

high temperature and pure zirconium was obtained.

Zr(s)

+ 2I2 (s) __ 550 K_→

ZrI4 (vapour)

ZrI4

(vapour) ___1800 K_→ Zr (s) + 2I2 (s)

(iv) Sodium cyanide

in froth floatation

Sodium

cyanide (NaCN) is added to depress the floatation property.

When

a sulphide ore of a metal contains other metal sulphides as impurities,

depressing agent sodium cyanide is used to selectively prevent other metal

sulphides from coming to the froth.

14. Explain the principle of electrolytic refining with an example.

The

crude metal is refined by electrolysis.

Anode - Impure

metal rod

Cathode - Thin

strips of pure metal

The

metal dissolves from the anode, pass into the solution while the same amount of

metal ions from the solution will be deposited at the cathode. The insoluble

impurities in the anode settles at the bottom of the anode as anode mud.

Example:

Electrolytic refining of silver

Cathode

: Pure silver

Anode

: Impure silver rods

Electrolyte

: Silver nitrate in HNO3

Reaction

at cathode

Ag+

(aq) + e− → Ag(s)

Reaction

at anode

Ag(s)

→ Ag+ (aq) + e−

During

electrolysis, at the anode the silver atoms lose electrons and enter the

solution. The positively charged silver cations migrate towards the cathode and

get discharged by gaining electrons and deposited on the cathode. The

impurities settle down at the bottom of anode as anode mud.

15. The selection of reducing agent depends on the thermodynamic factor: Explain with an example.

The

extraction of metals from their oxides can be carried out by using different

reducing agents.

2/y

MxOy(s) → 2x / y M(s) + O2(g)

The

above reduction may be carried out with carbon. The reducing agent carbon may

be oxidised to either CO or CO2.

C

+ O2 → CO2

2

C + O2 → 2 CO

If

carbon monoxide is used as a reducing agent, it is oxidised to CO2

as follows

2CO

+ O2 → 2 CO2

A

suitable reducing agent is selected based on the thermodynamic considerations.

The change in free energy (∆G) should be negative, for a spontaneous reaction.

Therefore, thermodynamically, the reduction of metal oxide with a given

reducing agent can occur if the free energy change for the coupled reaction is

negative. Hence, the reducing agent is selected in such a way that it provides

a large negative ∆G value for the coupled reaction.

16. Give the limitations of Ellingham diagram.

i)

Ellingham diagram is constructed based only on thermodynamic considerations. It

gives information about the thermodynamic feasibility of a reaction. It does

not tell anything about the rate of the reaction. Moreover, it does not give

any idea about the possibility of other reactions that might be taking place.

ii)

The interpretation of ∆G is based on the assumption that the reactants are in

equilibrium with the product which is not always true.

17. Write a short note on electrochemical principles of metallurgy.

The

reduction of oxides of active metals by carbon is thermodynamically not feasible.

Such metals are extracted by using electrochemical methods. The metal salts are

taken in a fused form or in solution form. The metal ion present can be reduced

by treating it with some suitable reducing agent or by electrolysis.

Gibbs

free energy change for the electrolysis process is given by the following

expression

∆G°

= −nFE°

Where

n is number of electrons involved in the reduction process

F

is the Faraday

E°

is the electrode potential of the redox couple.

If

E° is positive then the ∆G is negative and the reduction is spontaneous. When a

more reactive metal is added to the solution containing the relatively less

reactive metal ions, the more reactive metal will go into the solution.

For

example,

Cu

(s) + 2Ag+ (s) → Cu2+ (aq) + 2Ag(s)

Cu+2 (aq) + Zn(s) → Cu (s) + Zn+2 (aq)

EVALUATE YOURSELF:

1. Write the

equation for the extraction of silver by leaching with sodium cyanide and show

that the leaching process is a redox reaction.

In

the metallurgy of silver metal is leached with a dilute solution of NaCN in the

presence of air (O2).

4Ag

+ 8CN− + 2H2O + O2 → 4[Ag(CN)2]+

4OH−

In

this reaction, Ag → Ag+ oxidation number of Ag increases from 0 to

+1, hence oxidation

O2

→ OH− (oxidation number of oxygen decreases from 0 to −2, hence

reduction)

Hence

Leaching of silver is a redox reaction.

2. Magnesite

(Magnesium carbonate) is calcined to obtain magnesia, which is used to make

refractory bricks. Write the decomposition reaction.

Magnesite

(Magnesium carbonate) is heated in the absence of oxygen decomposes to form

Magnesium oxide (Magnesia)

MgCO3

→ MgO + CO2 ↑

3. Using Ellingham

diagram indicate the lowest temperature at which ZnO can be reduced to Zinc

metal by carbon. Write the overall reduction reaction at this temperature.

Ellingham

diagram for the formation of ZnO and CO intersects around 1233 K below this

temperature, Carbon line lies above Zinc line. Hence ZnO is more stable than CO

so the reduction is thermodynamically not feasible at this temperature range.

However

above 1233 K carbon line lies below the zinc line, hence carbon can be used as

a reducing agent above 1233 K.

2Zn

+ O2 → 2ZnO ………….. (1)

2C

+ O2 → 2CO …………… (2)

Reversing

(1) and adding with equation (2)

2ZnO

→ 2Zn + O2

2C

+O2 → 2CO

2ZnO

+ 2C → 2Zn + 2CO

ZnO

+ C → Zn + CO

4. Metallic sodium

is extracted by the electrolysis of brine (aq.NaCl). After electrolysis the

electrolytic solution becomes basic in nature. Write the possible electrode

reactions.

Sodium

metal is prepared by Down's process. This involves the electrolysis of fused

NaCl and CaCl2 at 873K. During electrolysis sodium is discharged at

the cathode and Cl2 is obtained at the anode.

NaCl(l)

→ Na+(melt) + Cl− (melt)

Cathode

: Na+(melt) + e− → Na(s)

Anode

: 2Cl− (aq) → Cl2(g) + 2e−

If

an aqueous solution of NaCl is electrolysed, H2 is evolved at

cathode and Cl2 is evolved at anode. NaOH is obtained in the

solution.

NaCl(aq)

___Electrolysis_→ Na+(aq) +

Cl− (aq)

Cathode

: 2H2O(I) + 2e− → H2(g) + 2OH−

(aq)

Anode

: Cl− (aq) → 1/2 Cl2(g) + 2e−

Na+

and OH− ions to form NaOH

Hence solution is basic in nature.

Related Topics