Metallurgy | Chemistry - Extraction of crude metal | 12th Chemistry : UNIT 1 : Metallurgy

Chapter: 12th Chemistry : UNIT 1 : Metallurgy

Extraction of crude metal

Extraction

of crude metal

The extraction of crude

metals from the concentrated ores is carried out in two steps namely, (i)

conversion of the ore into oxides of the metal of interest and (ii) reduction

of the metal oxides to elemental metals. In the concentrated ore, the metal

exists in positive oxidation state and hence it is to be reduced to its

elemental state. We can infer from the principles of thermodynamics, that the

reduction of oxide is easier when compared to reduction of other compounds of

metal and hence, before reduction, the ore is first converted into the oxide of

metal of interest.

Let us discuss some of

the common methods used to convert the concentrated ore into the oxides of the

metal of interest.

1. Conversion of ores into oxides

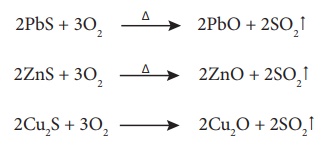

Roasting

Roasting is the method,

usually applied for the conversion of sulphide ores into their oxides. In this

method, the concentrated ore is oxidised by heating it with excess of oxygen in

a suitable furnace below the melting point of the metal.

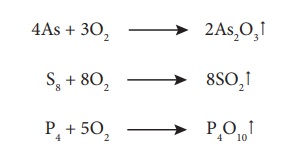

Roasting also removes

impurities such as arsenic, sulphur, phosphorous by converting them into their

volatile oxides.

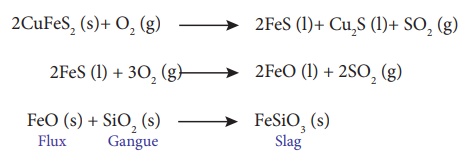

For example

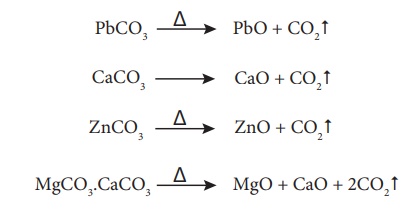

Calcination

Calcination is the

process in which the concentrated ore is strongly heated in the absence of air.

During this process, the water of crystallisation present in the hydrated oxide

escapes as moisture. Any organic matter (if present) also get expelled leaving

behind a porous ore. This method can also be carried out with a limited supply

of air.

For examples,

During calcination of

carbonate ore, carbon dioxide is expelled

During calcination of

hydrated ore, the water of hydration is expelled as vapour

2. Reduction of metal oxides

Metal oxide can be

reduced to crude metal by using a suitable reducing agent like carbon, carbon

monoxide, hydrogen, aluminium and other reactive metals such as sodium

etc...The choice of reducing agent depends on the nature of the metal. For

example, carbon cannot be used as a reducing agent for the reactive metals such

as sodium, potassium, aluminium etc...Similarly CO cannot be used to reduce

oxides such as ZnO, Al2O3. Later in this,we study

selection of suitable reducing agents by applying Ellingham diagram.

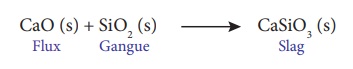

Smelting

In this method, a flux

(a chemical substance that forms an easily fusible slag with gangue) and a

reducing agent such as carbon, carbon monoxide (or) aluminium is added to the

concentrated ore and the mixture is melted by heating at an elevated

temperature (above the melting point of the metal) in a smelting furnace. For

example the oxide of iron can be reduced by carbon monoxide as follows.

Fe2O3

(s) + 3CO (g) → 2Fe (s) + 3CO2 (g) ↑

In this extraction, a

basic flux, limestone (CaO) is used. Since the silica gangue present in the ore

is acidic in nature, the limestone combines with it to form calcium silicate

(slag).

CaO(s) + SiO2 (s) → CaSiO3

(s)

Flux + Gangue → Slag

In the extraction of

copper from copper pyrites, the concentrated ore is heated in a reverberatory

furnace after mixing with silica, an acidic flux. The ferrous oxide formed due

to melting is basic in nature and it combines with silica to form ferrous

silicate (slag). The remaining metal sulphides Cu2S and FeS are mutually

soluble and form a copper matte.

2CuFeS2 (s)+ O2 (g) → 2FeS (l)+ Cu2S (l)+ SO2 (g)

2FeS (l) + 3O2 (g) → 2FeO (l) + 2SO2 (g)

FeO (s) + SiO2 (s) → FeSiO3 (s) { Flux + Gangue → Slag }

The matte is separated

from the slag and fed to the converting furnace. During conversion, the FeS

present in the matte is first oxidised to FeO. This is removed by slag

formation with silica. The remaining copper sulphide is further oxidised to its

oxide which is subsequently converted to metallic copper as shown below.

2Cu2S (l,s)

+ 3O2 (g) → 2Cu2O (l,s) + 2SO2 (g)

2Cu2O (l)

+ Cu2S (l) → 6Cu (l) + SO2 (g)

The metallic copper is

solidified and it has blistered appearance due to evolution of SO2

gas formed in this process. This copper is called blistered copper.

Reduction by carbon:

In this method the oxide

ore of the metal is mixed with coal (coke) and heated strongly in a furnace

(usually in a blast furnace). This process can be applied to the metals which

do not form carbides with carbon at the reduction temperature.

Examples:

ZnO (s)+ C (s) → Zn (s) + CO (g) ↑

Mn3O4 (s) + 4C (s) → 3Mn (s) + 4CO (g) ↑

Cr2O3 (s) + 3C (s) → 2Cr (s) + 3CO (g) ↑

Reduction by hydrogen:

This method can be

applied to the oxides of the metals (Fe, Pb, Cu) having less electro-positive

character than hydrogen.

Ag2O (s)+ H2 (g) → 2Ag (s) + H2O (l)

Fe3O4 (s) + 4H2 (g) → 3Fe (s) + 4H2O (l)

Nickel oxide can be

reduced to nickel by using a mixture of hydrogen and carbon monoxide (water

gas)

2NiO (s) + CO (g) + H2

(g) → 2Ni (s) + CO2 (g) + H2O (l)

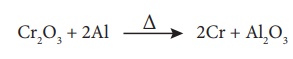

Reduction by metal:

Metallic oxides such as

Cr2O3 can be reduced by an aluminothermite process. In

this process, the metal oxide is mixed with aluminium powder and placed in a

fire clay crucible. To initiate the reduction process, an ignition mixture

(usually magneisium and barium peroxide) is used.

BaO2 + Mg → BaO

+ MgO

During the above

reaction a large amount of heat is evolved (temperature up to 2400°C, is

generated and the reaction enthalpy is : 852 kJ mol-1) which facilitates the

reduction of Cr2O3 by aluminium power.

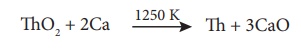

Active metals such as

sodium, potassium and calcium can also be used to reduce the metal oxide

B2O3

+ 6Na → 2B + 3Na2O

Rb2O3

+ 3Mg → 2Rb + 3MgO

TiO2 + 2Mg → Ti + 2MgO

Auto-reduction:

Simple roasting of some

of the ores give the crude metal. In such cases, the use of reducing agents is

not necessary. For example, mercury is obtained by roasting of its ore cinnabar

(HgS)

HgS (s) + O2 →

(g) Hg (l) + SO2↑

Related Topics