Metallurgy | Chemistry - Concentration of ores | 12th Chemistry : UNIT 1 : Metallurgy

Chapter: 12th Chemistry : UNIT 1 : Metallurgy

Concentration of ores

Concentration

of ores

Generally, the ores are

associated with non-metallic impurities, rocky materials and siliceous matter

which are collectively known as gangue. The preliminary step in metallurgical

process is removal of these impurities. This removal process is known as

concentration of ore. It increases the concentration of the metal of interest

or its compound in the ore. Several methods are available for this process and

the choice of method will depend on the nature of the ore, type of impurity and

environmental factors. Some of the common methods of ore concentration are

discussed below.

1. Gravity separation or Hydraulic wash

In this method, the ore

having high specific gravity is separated from the gangue that has low specific

gravity by simply washing with running water. Ore is crushed to a finely

powdered form and treated with rapidly flowing current of water. During this

process the lighter gangue particles are washed away by the running water. This

method is generally applied to concentrate the native ore such as gold and

oxide ores such as haematite (Fe2O3), tin stone (SnO2)

etc.

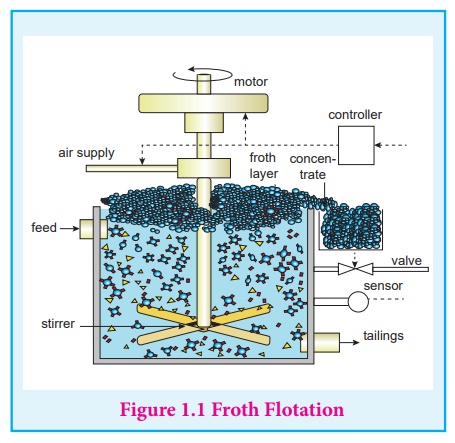

2. Froth flotation

This method is commonly

used to concentrate sulphide ores such as galena (PbS), zinc blende (ZnS)

etc... In this method, the metallic ore particles which are preferentially

wetted by oil can be separated from gangue.

In this method, the

crushed ore is suspended in water and mixed with frothing agent such as pine

oil, eucalyptus oil etc.

A small quantity of sodium

ethyl xanthate which acts as a collector is also added. A froth is generated by

blowing air through this mixture. The collector molecules attach to the ore

particle and make them water repellent. As a result, ore particles, wetted by

the oil, rise to the surface along with the froth. The froth is skimmed off and

dried to recover the concentrated ore. The gangue particles that are

preferentially wetted by water settle at the bottom.

When a sulphide ore of a

metal of interest contains other metal sulphides as impurities, depressing

agents such as sodium cyanide, sodium carbonate etc are used to selectively

prevent other metal sulphides from coming to the froth. For example, when

impurities such as ZnS is present in galena (PbS), sodium cyanide (NaCN) is

added to depresses the flotation property of ZnS by forming a layer of zinc

complex Na2[Zn(CN)4] on the surface of zinc sulphide.

3. Leaching

This method is based on

the solubility of the ore in a suitable solvent and the reactions in aqueous

solution. In this method, the crushed ore is allowed to dissolve in a suitable

solvent, the metal present in the ore is converted to its soluble salt or

complex while the gangue remains insoluble. The following examples illustrate

the leaching processes.

Cyanide leaching

Let us consider the

concentration of gold ore as an example. The crushed ore of gold is leached

with aerated dilute solution of sodium cyanide. Gold is converted into a

soluble cyanide complex. The gangue, aluminosilicate remains insoluble.

4Au (s) + 8CN-

(aq) + O2 (g) + 2H2O (l) → 4[Au(CN)2]-

(aq) + 4OH-(aq)

Recovery of metal of interest from the complex by reduction:

Gold can be recovered by

reacting the deoxygenated leached solution with zinc. In this process the gold

is reduced to its elemental state (zero oxidation sate) and the process is

called cementation.

Zn (s) + 2[Au(CN)2]-

(aq) → [Zn(CN)4]2-(aq) + 2Au (s)

Ammonia leaching

When a crushed ore

containing nickel, copper and cobalt is treated with aqueous ammonia under

suitable pressure, ammonia selectively leaches these metals by forming their

soluble complexes viz. [Ni(NH3)6]2+, [Cu(NH3)4]2+

, and [Co(NH3)5H2 O]3+ respectively

from the ore leaving behind the gangue, iron(III) oxides/hydroxides and

aluminosilicate.

Alkali leaching

In this method, the ore

is treated with aqueous alkali to form a soluble complex. For example, bauxite,

an important ore of aluminum is heated with a solution of sodium hydroxde or

sodium carbonate in the temperature range 470 - 520 K at 35 atm to form soluble

sodium meta-aluminate leaving behind the impurities, iron oxide and titanium

oxide.

Al2O3

(s) + 2NaOH (aq) + 3H2O (l) → 2Na[Al(OH)4] (aq)

The hot solution is

decanted, cooled, and diluted. This solution is neutralised by passing CO2

gas, to the form hydrated Al2O3 precipitate.

2Na[Al(OH)4]

(aq) + CO2 (g) → Al2O3.xH2O (s) +

2NaHCO3 (aq)

The precipitate is

filtered off and heated around 1670 K to get pure alumina Al2O3.

Acid leaching

Leaching of sulphide

ores such as ZnS, PbS etc., can be done by treating them with hot aqueous

sulphuric acid.

2ZnS (s) + 2H2SO4

(aq) + O2(g) → 2ZnSO4 (aq) + 2S (s) + H2O

In this process the

insoluble sulphide is converted into soluble sulphate and elemental sulphur.

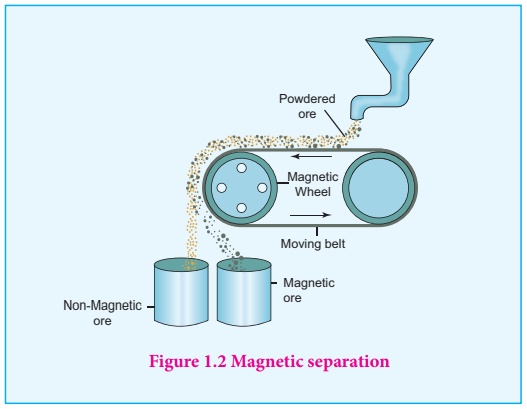

4. Magnetic separation

This method is

applicable to ferromagnetic ores and it is based on the difference in the

magnetic roperties of the ore and the impurities. For example tin stone can be

separated from the wolframite impurities which is magnetic. Similarly, ores

such as chromite, pyrolusite having magnetic property can be removed from the

non magnetic siliceous impurities. The crushed ore is poured on to an

electromagnetic separator consisting of a belt moving over two rollers of which

one is magnetic. The magnetic part of the ore is attracted towards the magnet

and falls as a heap close to the magnetic region while the nonmagnetic part

falls away from it as shown in the figure 1.2.

Related Topics