Chapter: Automation, Production Systems, and Computer Integrated Manufacturing : Manufacturing Operations

Manufacturing Operations

Manufacturing Operations

CONTENTS

I.

Manufacturing Industries and

Products

II.

Manufacturing Operations

a. Processing and Assembly Operations

b. Other Factory Operations

III.

Product/Production

Relationships

a. Production Quantity and Product Variety

b. Product and Part Complexity

c. Limitations and Capabilities of a Manufacturing

Plant

IV.

Production Concepts and

Mathematical Models

a. Production Rate

b. Plant Capacity

c. Utilization and Availability (Reliability)

d. Manufacturing Lead Time

e. WorkinProcess

V.

Costs of Manufacturing

Operations

a. Fixed and Variable Costs

b. Direct Labor, Material, and Overhead

c. Cost of Equipment Usage

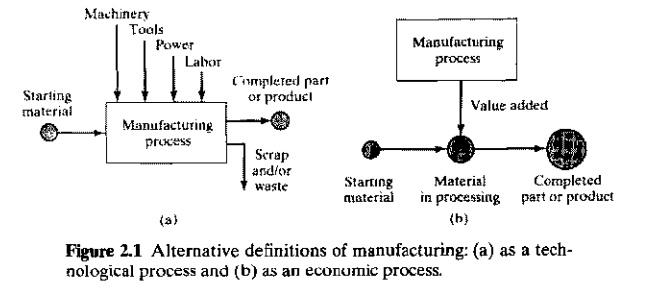

Manufacturing can be defined as the application of physical

and chemical processes to alter the

geometry, properties, and/or appearance of a given starting material to make

parts

or

products; manufacturing also includes the joining of multiple parts to make

assembled products. The processes that accomplish manufacturing involve a

combination of machinery, tools, power, and manual labor, as depicted in Figure

2.1(a). Manufacturing is almost always carried out as a sequence of operations.

Each successive operation brings the material closer to the desired final

state.

From an economic viewpoint, manufacturing is the transformation of

materials into items of greater value by means of one or more processing and/or

assembly operations, as depicted in Figure 2.1(b). The key point is that

manufacturing adds value to the

material by changing its shape or properties or by combining it with other

materials that have been similarly altered. The material has been made more

valuable through the manufacturing operations performed on it.When iron ore is

converted into steel, value is added.When sand is transformed into glass, value

is added. When petroleum is refined into plastic, value is added. And when

plastic is molded into the complex geometry of a patio chair, it is made even

more valuable.

In this chapter, we provide a survey of manufacturing operations.

We begin by examining the industries that are engaged in manufacturing and the

types of products they produce.We then discuss fabrication and assembly

processes used in manufacturing as well as the activities that support the

processes, such as material handling and inspection. The chapter concludes with

descriptions of several mathematical models of manufacturing operations. These

models help to define certain issues and parameters that are important in

manufacturing and to provide a quantitative perspective on manufacturing operations.

We might observe here that the manufacturing operations, the

processes in particular, emphasize the preceding technological definition of

manufacturing, while the production systems discussed in Chapter 1 stress the

economic definition. Our emphasis in this book is on the systems. The history

of manufacturing includes both the development of manufacturing processes, some

of which date back thousands of years, and the evolution of the production

systems required to apply and exploit these processes (Historical Note 2.1).

Historical Note 2.1 History of manufacturing

The history of manufacturing includes two

related topics: (1) man’s discovery and invention of materials and processes to

make things and (2) the development of systems of production. The materials and

processes predate the systems by several millennia. Systems of production refer

to the ways of organizing people and equipment so that production can be

performed more efficiently. Some of the basic processes date as far back as the

Neolithic period (circa 8000–3000 B.C.), when operations such as the following

were developed: woodworking, forming, and firing of clay pottery,

grinding and polishing of stone, spinning and weaving of textiles, and dyeing

of cloth. Metallurgy and metalworking also began during the Neolithic, in

Mesopotamia and other areas around the Mediterranean. It either spread to, or

developed independently in, regions of Europe and Asia. Gold was found by early

man in relatively pure form in nature; it could be hammered into shape. Copper was probably the first metal to be

extracted from ores, thus requiring smelting

as a processing technique. Copper could not be readily hammered because it

strainhardened; instead, it was shaped by casting.

Other metals used during this period were silver and tin. It was discovered

that copper alloyed with tin produced a more workable metal than copper alone

(casting and hammering could both be used). This heralded the important period

known as the Bronze Age (circa

3500–1500 B.C.).

Iron was also first smelted

during the Bronze Age. Meteorites may have been one source of the metal, but

iron ore was also mined. The temperatures required to reduce iron ore to metal

are significantly higher than for copper, which made furnace operations more

difficult. Other processing methods were also more difficult for the same reason.

Early blacksmiths learned that when certain irons (those containing small

amounts of carbon) were sufficiently heated

and then quenched, they became

very hard. This permitted the grinding of very sharp cutting edges on knives and weapons, but it also made the metal

brittle.Toughness could be increased by reheating at a lower temperature, a

process known as tempering. What we

have described is, of course, the heat

treatment of steel. The superior properties of steel caused it to succeed

bronze in many applications (weaponry, agriculture, and mechanical devices).

The period of its use has subsequently been named the Iron Age (starting around 1000 B.C.). It was not until much later,

well into the nineteenth century, that the demand for steel grew significantly

and more modern steelmaking techniques were developed.

The early fabrication of

implements and weapons was accomplished more as crafts and trades than by

manufacturing as we know it today. The ancient Romans had what might be called

factories to produce weapons, scrolls, pottery, glassware, and other products of

the time, but the procedures were largely based on handicraft. It was not until

the Industrial Revolution (circa

1760–1830) that major changes began to affect the systems for making things.

This period marked the beginning of the change from an economy based on

agriculture and handicraft to one based on industry and manufacturing. The

change began in England, where a series of important machines were invented,

and steam power began to replace water, wind, and animal power. Initially,

these advances gave British industry significant advantages over other nations,

but eventually the revolution spread to other European countries and to the

United States.The Industrial Revolution contributed to the development of

manufacturing in the following ways:

(1) Watt’s

steam engine, a new powergenerating technology; (2) development of machine tools, starting with John

Wilkinson’s boring machine around 1775, which was used to bore the cylinder on

Watt’s steam engine; (3) invention of the spinning

jenny, power loom, and other

machinery for the textile industry, which permitted significant increases in

productivity; and (4) the factory system,

a new way of organizing large numbers of production workers based on the

division of labor.

Wilkinson’s boring machine is

generally recognized as the beginning of machine tool technology. It was

powered by water wheel. During the period 1775–1850, other machine tools were

developed for most of the conventional machining

processes, such as boring, turning, drilling, milling, shaping, and planing. As steam power became more prevalent, it gradually became the preferred power source for

most of these machine tools. It is of interest to note that many of the

individual processes predate the machine tools by centuries; for example,

drilling and sawing (of wood) date from ancient times and turning (of wood)

from around the time of Christ.

Assembly methods were used in ancient cultures

to make ships, weapons, tools, farm implements, machinery, chariots and carts,

furniture, and garments. The processes included binding with twine and rope,

riveting and nailing, and soldering. By around the time of

Christ, forge welding and adhesive bonding had been developed.

Widespread use of screws, bolts, and nuts—so

common in today’s assembly—required the development of machine tools, in

particular, Maudsley’s screw cutting lathe (1800), which could accurately form

the helical threads. It was not until around 1900 that fusion welding processes started to be developed as assembly

techniques.

While England was leading the

Industrial Revolution, an important concept related to assembly technology was

being introduced in the United States: interchangeable

parts manufacture. Much credit for this concept is given to Eli Whitney

(1765–1825), although its importance had been recognized by others [2]. In

1797, Whitney negotiated a contract to produce 10,000 muskets for the U.S.

government. The traditional way of making guns at the time was to

custom–fabricate each part for a particular gun and then hand–fit the parts together

by filing. Each musket was therefore unique, and the time to make it was

considerable. Whitney believed that the components could be made accurately

enough to permit parts assembly without fitting. After several years of

development in his Connecticut factory, he traveled to Washington in 1801 to

demonstrate the principle. Before government officials, including Thomas

Jefferson, he laid out components for 10 muskets and proceeded to select parts

randomly to assemble the guns. No special filing or fitting was required, and

all of the guns worked perfectly. The secret behind his achievement was the

collection of special machines, fixtures, and gages that he had developed in

his factory. Interchangeable parts manufacture required many years of development

and refinement before becoming a practical reality, but it revolutionized

methods of manufacturing. It is a prerequisite for mass production of assembled

products. Because its origins were in the United States, interchangeable parts

production came to be known as the American

System of manufacture.

The mid and late1800s

witnessed the expansion of railroads, steam–powered ships, and other machines

that created a growing need for iron and steel. New methods for producing steel

were developed to meet this demand.Also during this period, several consumer

products were developed, including the sewing machine, bicycle, and automobile.

To meet the mass demand for these products, more efficient production methods

were required. Some historians identify developments during this period as the Second Industrial Revolution,

characterized in terms of its effects on production systems by the following:

(1) mass production, (2) assembly lines,

(3) scientific management movement, and (4)

electrification of factories.

Mass production was primarily an American phenomenon. Its motivation was the mass market that existed in the United

States. Population in the United States in 1900 was 76 million and growing. By

1920 it exceeded 106 million. Such a large population, larger than any western

European country, created a demand for large numbers of products. Mass

production provided those products. Certainly one of the important technologies

of mass production was the assembly line,

introduced by Henry Ford (1863–1947) in 1913 at his Highland Park plant

(Historical Note 17.1). The assembly line made mass production of complex

consumer products possible. Use of assembly line methods permitted Ford to sell

a Model T automobile for less than $500 in 1916, thus making ownership of cars

feasible for a large segment of the American population.

The scientific management movement started in the late 1800s in the

United States in response to the need to plan and control the activities of

growing numbers of production workers. The movement was led by Frederick W.

Taylor (1856–1915), Frank Gilbreath (1868–1924) and his wife Lilian

(1878–1972), and others. Scientific management included: (1) motion study, aimed at finding the best

method to perform a given task; (2) time

study, to establish work

standards for a job; (3) extensive use of standards

in industry; (4) the piece rate system

and similar labor incentive plans; and (5) use of data collection, record

keeping, and cost accounting in factory operations.

In 1881, electrification

began with the first electric power generating station being built in New York

City, and soon electric motors were being used as the power source to operate

factory machinery. This was a far more convenient power delivery system than

the steam engine, which required overhead belts to distribute power to the

machines. By 1920, electricity had overtaken steam as the principal power

source in U.S. factories. Electrification also motivated many new inventions

that have affected manufacturing operations and production systems.The

twentieth century has been a time of more technological advances than in all

other centuries combined. Many of these developments have resulted in the automation of manufacturing. Historical

notes on some of these advances in automation are covered in this book.

Related Topics