Chapter: Automation, Production Systems, and Computer Integrated Manufacturing : Introduction

Automation Principles and Strategies

AUTOMATION PRINCIPLES AND STRATEGIES

The

preceding discussion leads us to conclude that automation is not always the

right answer for a given production situation. A certain caution and respect

must be observed in applying automation technologies. In this section, we offer

three approaches for dealing with automation projects:2 (1) the USA

Principle, (2) the Ten Strategies for Automation and Production Systems, and

(3) an Automation Migration Strategy.

1.USA

Principle

The USA

Principle is a common sense approach to automation projects. Similar procedures

have been suggested in the manufacturing and automation trade literature, but

none has a more captivating title than this one. USA stands for:

1. Understand the existing process

2. Simplify the process

3. Automate the process.

A

statement of the USA principle appeared in an APICS3 article [4].

The article was concerned with implementation of enterprise resource planning

(ERP, Section 26.6), but the USA approach is so general that it is applicable

to nearly any automation project. Going through each step of the procedure for

an automation project may in fact reveal that simplifying the process is

sufficient and automation is not necessary.

Understand the Existing Process. The obvious purpose of the first step in the

USA approach is to comprehend the current process

in all of its details. What are the inputs? What are the outputs? What exactly

happens to the work unit between input and output? What is the function of the

process? How does it add value to the product? What are the upstream and

downstream operations in the production sequence, and can they be combined with

the process under consideration?

Some of the basic charting tools used in methods analysis are useful in

this regard,such as the operation process chart and the flow process chart [5].

Application of these tools to the existing process provides a model of the

process that can be analyzed and searched for weaknesses (and strengths). The

number of steps in the process, the number and placement of inspections, the

number of moves and delays experienced by the work unit, and the time spent in

storage can be ascertained by these charting techniques.

Mathematical models of the process may also be useful to indicate

relationships between input parameters and output variables. What are the

important output variables? How are these output variables affected by inputs

to the process, such as raw material properties, process settings, operating

parameters, and environmental conditions? This information may be valuable in

identifying what output variables need to be measured for feedback purposes and

in formulating algorithms for automatic process control.

Simplify the Process. Once the existing process is

understood, then the search can begin for ways to simplify.

This often involves a checklist of questions about the existing process. What

is the purpose of this step or this transport? Is this step necessary? Can this

step be eliminated? Is the most appropriate technology being used in this step?

How can this step be simplified? Are there unnecessary steps in the process

that might be eliminated without detracting from function?

Some of the ten strategies of automation and production systems (Section

1.5.2) are applicable to try to simplify the process. Can steps be combined?

Can steps be performed simultaneously? Can steps be integrated into a manually

operated production line?

Automate the Process. Once the process has been reduced

to its simplest form, then automation can be

considered. The possible forms of automation include those listed in the ten

strategies discussed in the following section. An automation migration strategy

(Section 1.5.3) might be implemented for a new product that has not yet proven

itself.

2.Ten

Strategies for Automation and Production

Systems

Following

the USA Principle is a good first step in any automation project. As suggested

previously, it may turn out that automation of the process is unnecessary or

cannot be cost justified after it has been simplified.

If automation seems a feasible solution to improving productivity,

quality, or other measure of performance, then the following ten strategies

provide a road map to search for these improvements. These ten strategies were

first published in my first book.4 They seem as relevant and

appropriate today as they did in 1980. We refer to them as strategies for

automation and production systems because some of them are applicable whether

the process is a candidate for automation or just for simplification.

Specialization

of operations. The first strategy involves the use of

special—purpose equipment designed to

perform one operation with the greatest possible efficiency. This is analogous

to the concept of labor specialization, which is employed to improve labor

productivity.

2. Combined operations.

Production occurs as a sequence of operations. Complex parts may require dozens, or even hundreds,

of processing steps. The strategy of combined operations involves reducing the

number of distinct production machines or workstations through which the part

must be routed. This is accomplished by performing more than one operation at a

given machine, thereby reducing the number of separate machines needed. Since

each machine typically involves a setup, setup time can usually be saved as a

consequence of this strategy. Material handling effort and nonoperation time

are also reduced. Manufacturing lead time is reduced for better customer

service.

3. Simultaneous operations. A

logical extension of the combined operations strategy is to simultaneously perform the operations that are combined at one

workstation. In effect, two or more processing (or assembly) operations are

being performed simultaneously on the same workpart, thus reducing total

processing time.

4. Integration of operations.Another strategy

is to link several workstations together into a single integrated mechanism, using automated work handling

devices to transfer parts between stations. In effect, this reduces the number

of separate machines through which the product must be scheduled. With more

than one workstation, several parts can be processed simultaneously, thereby

increasing the overall output of the system.

5. Increased flexibility. This

strategy attempts to achieve maximum utilization of equipment for job shop and

medium volume situations by using the same equipment for a variety of parts or

products. It involves the use of the flexible automation concepts (Section

1.3.1). Prime objectives are to reduce setup time and programming time for the

production machine. This normally translates into lower manufacturing lead time

and less workinprocess.

6. Improved material handling and storage. A great

opportunity for reducing nonproductive time exists in the use of automated

material handling and storage systems.Typical benefits include reduced

workinprocess and shorter manufacturing lead times.

7. Online inspection. Inspection for quality of work

is traditionally performed after the process

is completed. This means that any poor quality product has already been

produced by the time it is inspected. Incorporating inspection into the

manufacturing process permits corrections to the process as the product is

being made. This reduces scrap and brings the overall quality of product closer

to the nominal specifications intended by the designer.

8. Process control and optimization. This

includes a wide range of control schemes intended to operate the individual

processes and associated equipment more efficiently. By this strategy, the

individual process times can be reduced and product quality improved.

9. Plant operations control. Whereas

the previous strategy was concerned with the control of the individual

manufacturing process, this strategy is concerned with control at the plant

level. It attempts to manage and coordinate the aggregate operations in the

plant more efficiently. Its implementation usually involves a high level of

computer networking within the factory.

10.

Computerintegrated

manufacturing (CIM). Taking the previous strategy one level higher, we have the integration of

factory operations with engineering design and the business functions of the

firm. CIM involves extensive use of computer applications, computer data bases,

and computer networking throughout the enterprise.

The ten

strategies constitute a checklist of the possibilities for improving the

production system through automation or simplification. They should not be

considered as mutually exclusive. For most situations, multiple strategies can

be implemented in one improvement project.

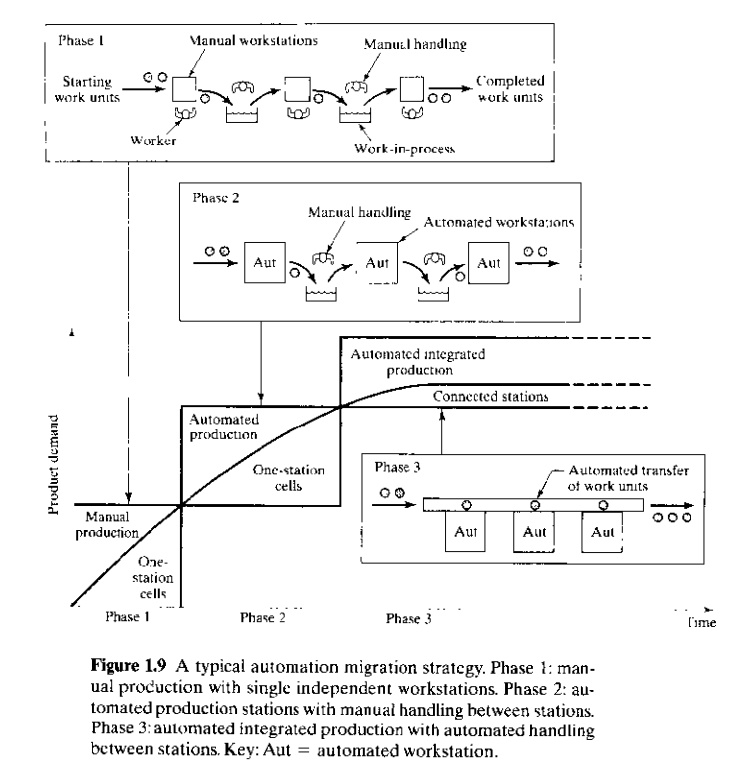

3

Automation Migration Strategy

Owing to

competitive pressures in the marketplace, a company often needs to introduce a

new product in the shortest possible time. As mentioned previously, the easiest

and least expensive way to accomplish this objective is to design a manual

production method, using a sequence of workstations operating independently.

The tooling for a manual method can be fabricated quickly and at low cost. If

more than a single set of workstations is required to make the product in

sufficient quantities, as is often the case, then the manual cell is replicated

as many times as needed to meet demand. If the product turns out to be

successful, and high future demand is anticipated, then it makes sense for the

company to automate production. The improvements are often carried out in phases.

Many companies have an automation

migration strategy, that is, a formalized plan for evolving the

manufacturing systems used to produce new products as demand grows. A typical

automation migration strategy is the following:

Phase 1: Manual

production using single station manned cells operating independently. This

is used for introduction of the new product for reasons already mentioned:

quick and low cost tooling to get started.

Phase 2: Automated

production using single station automated cells operating independently. As

demand for the product grows, and it becomes clear that automation can be

justified, then the single stations are automated to reduce labor and increase

production rate. Work units are still moved between workstations manually.

Phase 3: Automated

integrated production using a multistation automated system with serial

operations and automated transfer of work units between stations. When the

company is certain that the product will be produced in mass quantities and for

several years, then integration of the single station automated cells is

warranted to further reduce labor and increase production rate.

This

strategy is illustrated in Figure 1.9. Details of the automation migration

strategy vary from company to company, depending on the types of products they

make and the manufacturing processes they perform. But wellmanaged

manufacturing companies have policies like the automation migration strategy.

Advantages of such a strategy include:

• It allows

introduction of the new product in the shortest possible time, since production

cells based on manual workstations are the easiest to design and implement.

• It allows

automation to be introduced gradually (in planned phases), as demand for the

product grows, engineering changes in the product are made, and time is allowed

to do a thorough design job on the automated manufacturing system.

It avoids the commitment to a high level of

automation from the start, since there is always a risk that demand for the

product will not justify it.

Related Topics