Chapter: Automation, Production Systems, and Computer Integrated Manufacturing : Introduction

Production System Facilities

PRODUCTION SYSTEM FACILITIES

The facilities in the production system are

the factory, production machines and tooling, material handling equipment,

inspection equipment, and the computer systems that control the manufacturing

operations. Facilities also include the plant

layout, which is the way the equipment is physically arranged in the

factory. The equipment is usually arranged into logical groupings, and we refer

to these equipment arrangements and the workers who operate them as the manufacturing systems in the factory.

Manufacturing systems can be individual work cells, consisting of a single

production machine and worker assigned to that machine. We more commonly think

of manufacturing systems as groups of machines and workers, for example, a

production line. The manufacturing systems come in direct physical contact with

the parts and/or assemblies being made. They “touch” the product.

A

manufacturing company attempts to organize its facilities in the most efficient

way to serve the particular mission of that plant. Over the years, certain

types of production facilities have come to be recognized as the most

appropriate way to organize for a given type of manufacturing. Of course, one

of the most important factors that determine the type of manufacturing is the

type of products that are made. Our book is concerned primarily with

the

production of discrete parts and products, compared with products that are in

liquid or bulk form, such as chemicals (we examine the distinction in Section

2.1).

If we

limit our discussion to discrete products, the quantity produced by a factory

has a very significant influence on its facilities and the way manufacturing is

organized. Production quantity refers

to the number of units of a given part or product produced annually by the

plant. The annual part or product quantities produced in a given factory can be

classified into three ranges:

1. Low production: Quantities in the range of 1 to

100 units per year.

2. Medium production: Quantities in the range of 100

to 10,000 units annually.

3. High production: Production quantities are

10,000 to millions of units.

The

boundaries between the three ranges are somewhat arbitrary (author’s judgment).

Depending on the types of products we are dealing with, these boundaries may

shift by an order of magnitude or so.

Some

plants produce a variety of different product types, each type being made in

low or medium quantities. Other plants specialize in high production of only

one product type. It is instructive to identify product variety as a parameter

distinct from production quantity. Product

variety refers to the different product designs or types that are produced

in a plant. Different products have different shapes and sizes and styles; they

perform different functions; they are sometimes intended for different markets;

some have more components than others; and so forth. The number of different

product types made each year can be counted. When the number of product types

made in a factory is high, this indicates high product variety.

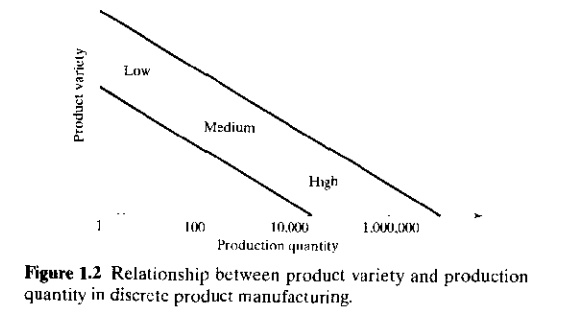

There is

an inverse correlation between product variety and production quantity in terms

of factory operations. When product variety is high, production quantity tends

to be low; and vice versa. This relationship is depicted in Figure 1.2.

Manufacturing plants tend to specialize in a combination of production quantity

and product variety that lies somewhere inside the diagonal band in Figure 1.2.

In general, a given factory tends to be limited to the product variety value

that is correlated with that production quantity.

Figure 1.2 Relationship

between product variety and production quantity

in discrete product manufacturing.

Although

we have identified product variety as a quantitative parameter (the number of

different product types made by the plant or company), this parameter is much

less exact than production quantity is because details on how much the designs

differ is not captured simply by the number of different designs. The

differences between an automobile and an air conditioner are far greater than

between an air conditioner and a heat pump. Products can be different, but the

extent of the differences may be small or great. The automotive industry

provides some examples to illustrate this point. Each of the U.S. automotive

companies produces cars with two or three different nameplates in the same

assembly plant, although the body styles and other design features are nearly

the same. In different plants, the same auto company builds heavy trucks. Let

us use the terms “hard” and “soft” to describe these differences in product

variety. Hard product variety is when

the products differ substantially. In an assembled product, hard variety is

characterized by a low proportion of common parts among the products; in many

cases, there are no common parts. The difference between a car and a truck is

hard. Soft product variety is when

there are only small differences between products, such as the differences

between car models made on the same production line. There is a high proportion

of common parts among assembled products whose variety is soft. The variety

between different product categories tends to be hard; the variety between

different models within the same product category tends to be soft.

We can

use the three production quantity ranges to identify three basic categories of

production plants. Although there are variations in the work organization

within each category, usually depending on the amount of product variety, this

is nevertheless a reasonable way to classify factories for the purpose of our

discussion.

1 Low

Quantity Production

The type

of production facility usually associated with the quantity range of 1 to 100

units/year is the job shop, which

makes low quantities of specialized and customized products. The products are

typically complex, such as space capsules, aircraft, and special machinery. Job

shop production can also include fabricating the component parts for the

products. Customer orders for these kinds of items are often special, and

repeat orders may never occur. Equipment in a job shop is general purpose and

the labor force is highly skilled.

A job

shop must be designed for maximum flexibility to deal with the wide part and

product variations encountered (hard product variety). If the product is large

and heavy, and therefore difficult to move in the factory, it typically remains

in a single location, at least during its final assembly. Workers and

processing equipment are brought to the product, rather than moving the product

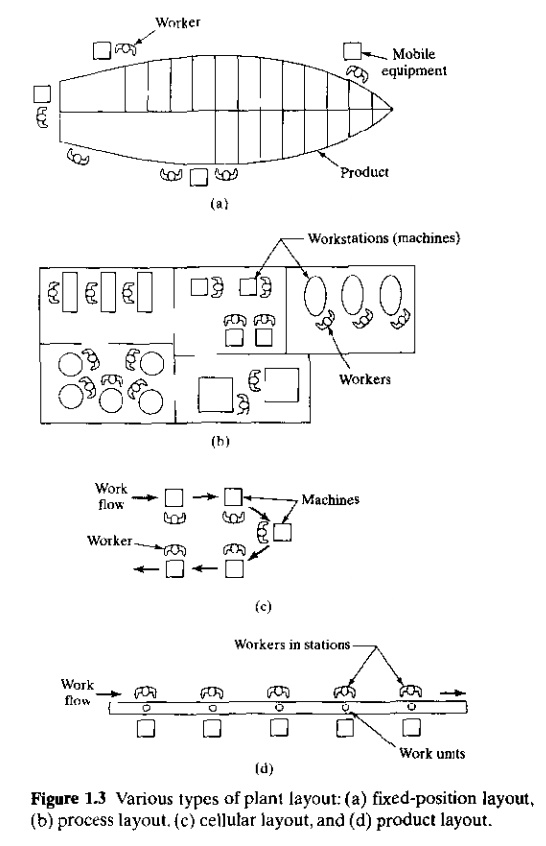

to the equipment. This type of layout is referred to as a fixed–position layout, shown in Figure 1.3(a). In the pure

situation, the product remains in a

single location during its entire fabrication. Examples of such products

include ships, aircraft, railway locomotives, and heavy machinery. In actual

practice, these items are usually built in large modules at single locations,

and then the completed modules are brought together for final assembly using

largecapacity cranes.

The

individual parts that comprise these large products are often made in factories

that have a process layout, in which

the equipment is arranged according to function or type. The lathes are in one

department, the milling machines are in another department, and so on, as in

Figure 1.3(b). Different parts, each requiring a different operation sequence,

are routed

through the departments in the particular order needed for their processing,

usually in batches. The process layout is noted for its flexibility; it can

accommodate a great variety of alternative operation sequences for different

part configurations. Its disadvantage is that the machinery and methods to

produce a part are not designed for high efficiency. Much material handling is

required to move parts between departments, so inprocess inventory can be high.

2 Medium

Quantity Production

In the

medium quantity range (100–10,000 units annually), we distinguish between two

different types of facility, depending on product variety. When product variety

is hard, the traditional approach is batch

production, in which a batch of one product is made, after which the

facility is changed over to produce a batch of the next product, and so on.

Orders for each product are frequently repeated. The production rate of the

equipment is greater than the demand rate for any single product type, and so

the same equipment can be shared among multiple products. The changeover

between production runs takes time. Called the setup time or changeover time,

it is the time to change tooling and to set up and reprogram the machinery.

This is lost production time, which is a disadvantage of batch manufacturing.

Batch production is commonly used in maketostock situations, in which items are

manufactured to replenish inventory that has been gradually depleted by demand.

The equipment is usually arranged in a process layout, Figure 1.3(b).

An

alternative approach to medium range production is possible if product variety

is soft. In this case, extensive changeovers between one product style and the

next may not be required. It is often possible to configure the equipment so

that groups of similar parts or products can be made on the same equipment

without significant lost time for changeovers. The processing or assembly of

different parts or products is accomplished in cells consisting of several

workstations or machines. The term cellular

manufacturing is often associated with this type of production. Each cell

is designed to produce a limited variety of part configurations; that is, the

cell specializes in the production of a given set of similar parts or products,

according to the principles of group

technology (Chapter 15). The layout is called a cellular layout, depicted in Figure 1.3(c).

3 High

Production

The high

quantity range (10,000 to millions of units per year) is often referred to as mass production.

The situation is characterized by a high demand rate for the product, and the production facility is dedicated to the

manufacture of that product.Two categories of mass production can be

distinguished: (1) quantity production and (2) flow line production. Quantity production involves the mass

production of single parts on single pieces of equipment. The method of

production typically involves standard machines (such as stamping presses)

equipped with special tooling (e.g., dies and material handling devices), in

effect dedicating the equipment to the production of one part type. The typical

layout used in quantity production is the process layout, Figure 1.3(b).

Flow line production involves

multiple workstations arranged in sequence, and the parts or assemblies are physically moved through the sequence to

complete the product. The workstations consist of production machines and/or

workers equipped with specialized tools. The collection of stations is designed

specifically for the product to maximize efficiency. The layout is called a product layout, and the workstations are

arranged into one long line, as in Figure 1.3(d), or into a series of connected

line segments. The work is usually moved between stations by powered conveyor.

At each station, a small amount of the total work is completed on each unit of

product.

The most

familiar example of flow line production is the assembly line, associated with

products such as cars and household appliances. The pure case of flow line

production is where there is no variation in the products made on the line.

Every product is identical, and the line is referred to as a single model production line. However,

to successfully market a

given

product, it is often necessary to introduce model variations so that individual

customers can choose the exact style and options that appeal to them. From a

production viewpoint, the model differences represent a case of soft product

variety. The term mixed–model production

line applies to those situations where there is soft variety in the products made on the line. Modern

automobile assembly is an example. Cars coming off the assembly line have

variations in options and trim representing different models (and, in many

cases, different nameplates) of the same basic car design.

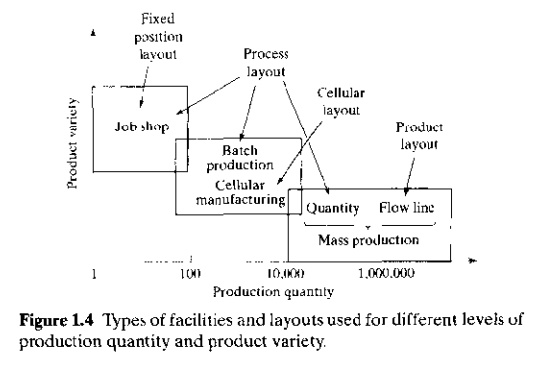

Much of

our discussion of the types of production facilities is summarized in Figure

1.4, which adds detail to Figure 1.2 by identifying the types of production

facilities and plant layouts used. As the figure shows, some overlap exists

among the different facility types.

Related Topics