Chapter: Automation, Production Systems, and Computer Integrated Manufacturing : Manufacturing Operations

Production Concepts and Mathematical Models

PRODUCTION CONCEPTS AND

MATHEMATICAL MODELS

A number of production concepts are

quantitative, or they require a quantitative approach to measure them. The

purpose of this section is to define some of these concepts. In subsequent chapters,

we refer back to these production concepts in our discussion of specific topics

in automation and production systems. The models developed in this section are

ideal, in the sense that they neglect some of the realities and complications

that are present in the factory. For example, our models do not include the

effect of scrap rates. In some manufacturing operations, the percentage of

scrap produced is high enough to adversely affect production rate, plant

capacity, and product costs. Most of these issues are considered in later

chapters as we focus on specific types of production systems.

1 Production Rate

The production rate for an

individual processing or assembly operation is usually expressed as an hourly

rate, that is, parts or products per hour. Let us consider how this rate is

determined for the three types of production: job shop production, batch

production, and mass production.

For any production operation,

the operation cycle time Tc

is defined as the time that one work unit spends being processed or assembled.

It is the time between when one work unit begins processing (or assembly) and

when the next unit begins. Tc

is the time an individual part spends at the machine, but not all of this time

is productive (recall the Merchant study, Section 2.2.2). In a typical

processing operation, such as machining, Tc

consists of: (1) actual machining operation time, (2) workpart handling time,

and (3) tool handling time per workpiece. As an equation, this can be

expressed:

where Tc=operation cycle time (min pc), To=time of the actual processing or assembly operation

(min pc), Th=handling time

(min pc), and Tth=tool

handling time (min pc). The tool handling time consists of time spent changing

tools when they wear out, time changing from one tool to the next, tool

indexing time for indexable inserts or for tools on a turret lathe or turret

drill, tool repositioning for a next pass, and so on. Some of these tool

handling activities do not occur every cycle; therefore, they must be spread over

the number of parts between their occurrences to obtain an average time per

workpiece.

where Tb=batch processing time (min), Tsu=setup time to prepare for the batch( min), Q=batch

quantity (pc), and Tc=operation

cycle time per work unit (min cycle). We assume that one work unit is completed

each cycle and so Tc also

has units of min pc. If more than one part is produced each cycle, then Eq.

(2.9) must be adjusted accordingly. Dividing batch time by batch quantity, we

have the average production time per work unit Tp for the given machine:

The average production rate

for the machine is simply the reciprocal of production time. It is usually

expressed as an hourly rate:

where Rp=hourly

production rate (pc hr), Tp=average

production time per minute (min pc), and the constant 60 converts minutes to

hours.

For job shop production when quantity Q=1, the production time per work

unit is the sum of setup and operation cycle times:

For job shop production when

the quantity is greater than one, then this reverts to the batch production

case discussed above.

For quantity type mass production, we can say that the production rate

equals the cycle rate of the machine (reciprocal of operation cycle time) after

production is underway and the effects of setup time become insignificant. That

is, as Q becomes very large, A Tsu QB S

0 and

where Rc=operation

cycle rate of the machine (pc hr), and Tc=operation

cycle time (min pc).

For flow line mass production, the production rate approximates the

cycle rate of the production line, again neglecting setup time. However, the

operation of production lines is complicated by the interdependence of the

workstations on the line. One complication is that it is usually impossible to

divide the total work equally among all of the workstations on the line;

therefore, one station ends up with the longest operation time, and this

station sets the pace for the entire line. The term bottleneck station is sometimes used to refer to this station. Also

included in the cycle time is the time to move parts from one station to the

next at the end of each operation. In many production lines, all work units on

the line are moved simultaneously, each to its respective next station. Taking

these factors into account, the cycle time of a production line is the sum of

the longest processing (or assembly) time plus the time to transfer work units

between stations. This can be expressed:

where Tc=cycle time of the production line (min cycle), Tr=time to transfer work

units between stations each cycle (min pc), and Max To=operation time at the bottleneck station (the maximum

of the operation times for all stations on the line, min cycle). Theoretically,

the production rate can be determined by taking the reciprocal of Tc as follows:

where Rc=theoretical

or ideal production rate, but let us call it the cycle rate to be more precise

(cycles hr), and Tc=ideal

cycle time from Eq. (2.14) (min cycle).

Production lines are of two

basic types: (1) manual and (2) automated. In the operation of automated

production lines, another complicating factor is reliability. Poor reliability

reduces the available production time on the line. This results from the interdependence

of workstations in an automated line, in which the entire line is forced to

stop when one station breaks down. The actual average production rate Rp is reduced to a value that

is often substantially below the ideal Rc

given by Eq. (2.15). We discuss reliability and some of its terminology in

Section 2.4.3. The effect of reliability on automated production lines is

examined in Chapters 18 and 19.

It is important to design the

manufacturing method to be consistent with the pace at which the customer is

demanding the part or product, sometimes referred to as the takt time (a German word for cadence or

pace). The takt time is the reciprocal of demand rate, but adjusted for the

available shift time in the factory. For example, if 100 product units were

demanded from a customer each day, and the factory operated one shift day, with

400 min of time available per shift, then the takt time would be 400 min 100

units=4.0 min work unit.

2 Production

Capacity

We mentioned production capacity in our

discussion of manufacturing capabilities (Section 2.3.3). Production capacity is defined as the maximum rate of output that a

production facility (or production line, work center, or group of work centers)

is able to produce under a given set of assumed operating conditions. The

production facility usually refers to a plant or factory, and so the term plant capacity is often used for this

measure. As mentioned before, the assumed operating conditions refer to the

number of shifts per day (one, two, or three), number of days in the week (or

month) that the plant operates, employment levels, and so forth.

The number of hours of plant

operation per week is a critical issue in defining plant capacity. For

continuous chemical production in which the reactions occur at elevated

temperatures, the plant is usually operated 24 hr day, 7 day wk. For an

automobile assembly plant, capacity is typically defined as one or two shifts.

In the manufacture of discrete parts and products, a growing trend is to define

plant capacity for the full 7day week, 24 hr day. This is the maximum time

available (168 hr wk), and if the plant operates fewer hours than the maximum,

then its maximum possible capacity is not being fully utilized.

Quantitative measures of

plant capacity can be developed based on the production rate models derived

earlier. Let PC=the production capacity of a given facility under

consideration. Let the measure of capacity=the number of units produced per

week. Let n=the number of machines or work centers in the facility. A work center is a manufacturing system in

the plant typically consisting of one worker and one machine. It might also be

one automated machine with no worker, or multiple workers working together on a

production line. It is capable of producing at a rate Rp unit hr, as defined in Section 2.4.1. Each work

center operates for H hr shift. Provision for setup time is included in Rp , according to Eq. (2.11).

Let S denote the number of shifts per week. These parameters can be combined to

calculate the production capacity of the facility:

where PC=production capacity of the facility

(output units wk), n=number of work centers producing in the facility, S=number

of shifts per period (shift wk), H=hr shift (hr), and Rp=hourly production rate of each work center (output

units hr). Although we have used a week as the time period of interest, Eq.

(2.16) can easily be revised to adopt other periods (months, years, etc.). As

in previous equations, our assumption is that the units processed through the

group of work centers are homogeneous, and therefore the value of Rp is the same for all units

produced.

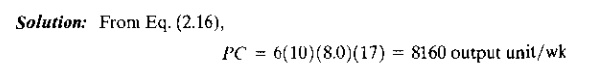

EXAMPLE 2.3 Production Capacity

The turret lathe section has

six machines, all devoted to the production of the same part. The section

operates 10 shift wk. The number of hours per shift averages 8.0. Average

production rate of each machine is 17 unit hr. Determine the weekly production

capacity of the turret lathe section.

If we include the possibility

that each work unit is routed through no operations, with each

operation requiring a new setup on either the same or different machine, then

the plant capacity equation must be amended as follows:

where no=number of distinct

operations through which work units are routed, and the other terms have the

same meaning as before.

Eq. (2.17) indicates the

operating parameters that affect plant capacity. Changes that can be made to

increase or decrease plant capacity over the short term are:

1. Change the number of shifts per week (S). For

example, Saturday shifts might be authorized to temporarily increase capacity.

2. Change the number of hours worked per shift

(H). For example, overtime on each regular shift might be authorized to

increase capacity.

Over the intermediate or longer term, the

following changes can be made to increase plant capacity:

3. Increase the number of work centers, n, in the

shop. This might be done by using equipment that was formerly not in use and

hiring new workers. Over the long term, new machines might be acquired.

Decreasing capacity is easier, except for the social and economic impact:

Workers must be laid off and machines decommissioned.

4. Increase the production rate, Rp by making improvements in

methods or process technology.

5. Reduce the number of operations no

required per work unit by using combined operations, simultaneous operations,

or integration of operations (Section 1.5.2: strategies 2, 3, and 4).

This capacity model assumes

that all n machines are producing 100% of the time, and there are no bottleneck

operations due to variations in process routings to inhibit smooth flow of work

through the plant. In real batch production machine shops where each product

has a different operation sequence, it is unlikely that the work distribution

among the productive resources (machines) can be perfectly balanced.

Consequently, there are some operations that are fully utilized while other

operations occasionally stand idle waiting for work. Let us examine the effect

of utilization.

3 Utilization and Availability

Utilization refers

to the amount of output of a production facility relative to its capacity. Expressing this as an equation,

where U=utilization of the facility, Q=actual

quantity produced by the facility during a given time period (i.e., pc wk), and

PC=production capacity for the same period (pc wk).

Utilization can be assessed

for an entire plant, a single machine in the plant, or any other productive

resource (i.e., labor). For convenience, it is often defined as the proportion

of time that the facility is operating relative to the time available under the

definition of capacity. Utilization is usually expressed as a percentage.

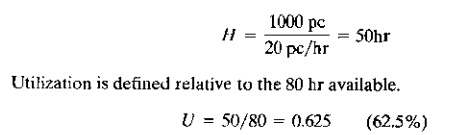

EXAMPLE 2.4 Utilization

A production machine operates 80 hr wk (two

shifts, 5 days) at full capacity. Its production rate is 20 unit hr. During a

certain week, the machine produced 1000 parts and was idle the remaining time.

(a) Determine the production capacity of the machine. (b) What was the

utilization of the machine during the week under consideration?

Solution: (a)

The capacity of the machine can be determined using the assumed 80hr week as

follows:

PC=80(20)=1600 unit wk

(b) tilization can be determined as the ratio

of the number of parts made by the machine relative to its capacity.

U=1000 1600=0.625 (62.5%)

The alternative way of

assessing utilization is by the time during the week that the machine was

actually used. To produce 1000 units, the machine was operated

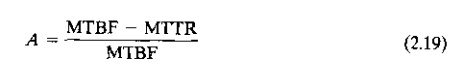

Availability is a

common measure of reliability for equipment. It is especially appropriate for

automated production equipment. Availability is defined using two other

reliability terms, mean time between failure

(MTBF) and mean time to repair

(MTTR). The MTBF indicates the average length of time the piece of equipment

runs between breakdowns. The MTTR indicates the average time required to

service the equipment and put it back into operation when a breakdown occurs.

Availability is defined as follows:

where A=availability,

MTBF=mean time between failures (hr), and MTTR=mean time to repair (hr).

Availability is typically expressed as a percentage. When a piece of equipment

is brand new (and being debugged), and later when it begins to age, its

availability tends to be lower.

EXAMPLE 2.5 Effect of Utilization and Availability on

Plant Capacity

Consider previous Example 2.3. Suppose the same

data from that example were applicable, but that the availability of the

machines A=90%, and the utilization of the machines U=80%. Given this

additional data, compute the expected plant output.

Solution: Previous Eq. (2.16) can

be altered to include availability and utilization as follows

where A=availability and U= utilization.

Combining the previous and new data, we have

Q=0.90(0.80)(6)(10)(8.0)(17)=5875

output unit wk

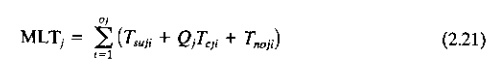

4 Manufacturing Lead Time

In the competitive environment of modern

business, the ability of a manufacturing firm to deliver a product to the

customer in the shortest possible time often wins the order. This time is

referred to as the manufacturing lead time. Specifically, we define manufacturing lead time (MLT) as the total time required to process a given part or

product through the plant. Let us

examine the components of MLT.

Production usually consists

of a series of individual processing and assembly operations. Between the

operations are material handling, storage, inspections, and other nonproductive

activities. Let us therefore divide the activities of production into two main

categories, operations and non-operation elements. An operation is performed on

a work unit when it is in the production machine. The non-operation elements

include handling, temporary storage, inspections, and other sources of delay

when the work unit is not in the machine. Let Tc=the operation cycle time at a given machine or

workstation, and Tno=the

non-operation time associated with the same machine. Further, let us suppose that the number of separate operations

(machines) through which the work unit must be routed to be completely

processed=no . If we assume batch production, then there are Q work

units in the batch. A setup is generally required to prepare each production

machine for the particular product, which requires a time=Tsu . Given these terms, we can define manufacturing

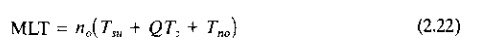

lead time as:

where MLTj=manufacturing lead time

for part or product j (min), Tsuji=setup

time for operation i (min), Qj=

quantity of part or product j in the batch being processed (pc),

Tcji=operation cycle time for operation i (min pc), Tnoji= non operation time associated with operation i (min), and i

indicates the operation sequence in the processing;

i=1, 2, p noj . The MLT equation does not

include the time the raw workpart spends in storage before its turn in the

production schedule begins.

To simplify and generalize

our model, let us assume that all setup times, operation cycle times, and

nonoperation times are equal for the noj machines. Further, let us

suppose that the batch quantities of all parts or products processed through

the plant are equal and that they are all processed through the same number of

machines, so that noj=no. With these simplifications, Eq.

(2.21) becomes:

where MLT=average manufacturing lead time for a

part or product (min).

In an actual batch production

factory, which this equation is intended to represent, the terms no,

Q, Tsu, Tc, and Tno would vary by product and by operation. These

variations can be accounted for by using properly weighted average values of

the various terms. The averaging procedure is explained in the Appendix at the

end of this chapter.

EXAMPLE 2.6 Manufacturing Lead Time

A certain part is produced in a batch size of

100 units. The batch must be routed through five operations to complete the

processing of the parts. Average setup time is 3 hr operation, and average

operation time is 6 min (0.1 hr). Average non operation time due to handling,

delays, inspections, etc., is 7 hours for each operation. Determine how many

days it will take to complete the batch, assuming the plant runs one 8hr shift

day.

Solution: The

manufacturing lead time is computed from Eq. (2.22)

MLT=5(3+100*0.1+7)=100 hours

At 8 hr day, this amounts to

100 8=12.5 days.

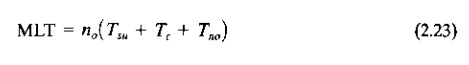

Eq. (2.22) can be adapted for

job shop production and mass production by making adjustments in the parameter

values. For a job shop in which the batch size is one (Q=1), Eq. (2.22) becomes

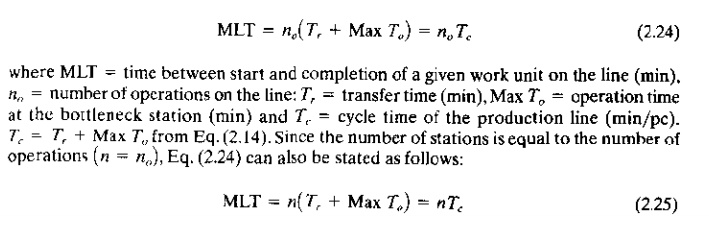

For mass production, the Q

term in Eq. (2.22) is very large and dominates the other terms. In the case of

quantity type mass production in which a large number of units are made on a

single machine A no=1B , the MLT simply becomes the operation cycle

time for the machine after the setup has been completed and production begins.

For flow line mass

production, the entire production line is set up in advance. Also, the

nonoperation time between processing steps is simply the transfer time Tr to move the part or

product from one workstation to the next. If the workstations are integrated so

that all stations are processing their own respective work units, then the time

to accomplish all of the operations is the time it takes each work unit to progress

through all of the stations on the line. The station with the longest operation

time sets the pace for all stations.

where MLT=time between start

and completion of a given work unit on the line (min), no=number of

operations on the line; Tr=transfer

time (min), Max To=operation

time at the bottleneck station (min) and Tc=cycle

time of the production line (min pc).

where the symbols have the same meaning as

above, and we have substituted n (number of workstations or machines) for number

of operations no .

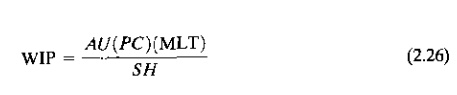

5 Work-in-Process

Work-in-process

(WIP) is the quantity of parts or products

currently located in the factory that are either being processed or are between

processing operations. WIP is inventory that is in the state of being transformed

from raw material to finished product. An approximate measure of work-in-process

can be obtained from the following, using terms previously defined:

where WIP=workinprocess in the facility (pc),

A=availability, U=utilization, PC=production capacity of the facility (pc wk),

MLT=manufacturing lead time, (wk), S=number of shifts per week (shift wk), and

H=hours per shift (hr shift). Eq. (2.26) states that the level of WIP equals

the rate at which parts flow through the factory multiplied by the length of

time the parts spend in the factory. The units for (PC) SH (e.g., pc wk) must

be consistent with the units for MLT (e.g., weeks).

Work-in-process represents an

investment by the firm, but one that cannot be turned into revenue until all processing

has been completed. Many manufacturing companies sustain major costs because

work remains in-process in the factory too long.

Related Topics