Chapter: Mechanical and Electrical : Thermal Engineering : Internal Combustion Engines

Lubrication System

Lubrication

System:

Does anyone know the importance of lubrication and

cooling systems in an engine?

The

lubrication and cooling system of an internal- combustion engine is very

important. If the lubricating system should fail, not only will the engine

stop, but many of the parts are likely to be damage beyond repair. Coolant

protects your engine from freezing or overheating.

What lubrication system does for an engine?

1. The job

of the lubrication system is to distribute oil to the moving parts to reduce

friction between surfaces which rub against each other.

2. An oil

pump is located on the bottom of the engine.

3. The pump

is driven by a worm gear off the main exhaust valve cam shaft.

4. The oil

is pumped to the top of the engine inside a feed line.

5. Small

holes in the feed line allow the oil to drip inside the crankcase.

6. The oil

drips onto the pistons as they move in the cylinders, lubricating the surface

between the piston and cylinder.

7. The oil

then runs down inside the crankcase to the main bearings holding the

crankshaft.

8. Oil is

picked up and splashed onto the bearings to lubricate these surfaces.

9. Along the

outside of the bottom of the crankcase is a collection tube which gathers up

the used oil and returns it to the oil pump to be circulated again.

Purpose of Lubrication System

Lubricate

Ø Reduces

Friction by creating a thin film(Clearance) between moving parts (Bearings and

journals)

Seals

Ø The oil

helps form a gastight seal between piston rings and cylinder walls (Reduces

Blow-By)

Ø Internal

oil leak (blow-by) will result in blue smoke at the tale pipe.

Cleans

Ø As it

circulates through the engine, the oil picks up metal particles and carbon, and

brings them back down to the pan.

Absorbs shock

Ø When

heavy loads are imposed on the bearings, the oil helps to cushion the load.

Viscosity:

Ø Viscosity

is a measure of oil’s resistance to flow.

Ø A low

viscosity oil is thin and flows easily

Ø A high

viscosity oil is thick and flows slowly.

Ø As oil

heats up it becomes more viscous (Becomes thin)

Proper lubrication of an engine is a complex

process.

Motor oil must perform many

functions under many different operating conditions. The primary functions of

oil are listed below:

1. Provide a

barrier between moving parts to reduce friction, heat buildup, and wear.

2. Disperse

heat. Friction from moving parts and combustion of fuel produce heat that must

be carried away.

3. Absorb

and suspend dirt and other particles. Dirt and carbon particles need to be

carried by the oil to the oil filter where they can be trapped.

4. Neutralize

acids that can build up and destroy polished metal surfaces.

5. Coat all

engine parts. Oil should have the ability to leave a protective coating on all

parts when the engine is turned off to prevent rust and corrosion.

6. Resist

sludge and varnish buildup. Oil must be able to endure extreme heat without

changing in physical properties or breaking down.

7. Stay

fluid in cold weather; yet remain thick enough to offer engine

What the cooling system does for an engine.

1. Although

gasoline engines have improved a lot, they are still not very efficient at

turning chemical energy into mechanical power.

2. Most of

the energy in the gasoline (perhaps 70%) is converted into heat, and it is the

job of the cooling system to take care of that heat. In fact, the cooling

system on a car driving down the freeway dissipates enough heat to heat two

average-sized houses!

3. The

primary job of the cooling system is to keep the engine from overheating by

transferring this heat to the air, but the cooling system also has several

other important jobs.

4. The

engine in your car runs best at a fairly high temperature.

5. When the

engine is cold, components wear out faster, and the engine is less efficient

and emits more pollution.

6. So

another important job of the cooling system is to allow the engine to heat up

as quickly as possible, and then to keep the engine at a constant temperature.

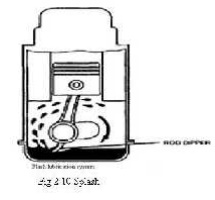

1Splash:

The splash system is no longer

used in automotive engines. It is widely used in small four-cycle engines for

lawn mowers, outboard marine operation, and so on. In the splash lubricating

system , oil is splashed up from the oil pan or oil trays in the lower part of

the crankcase. The oil is thrown upward as droplets or fine mist and provides

adequate lubrication to valve mechanisms, piston pins, cylinder walls, and

piston rings.

In the engine, dippers on the

connecting-rod bearing caps enter the oil pan with each crankshaft revolution

to produce the oil splash. A passage is drilled in each connecting rod from the

dipper to the bearing to ensure lubrication. This system is too uncertain for

automotive applications. One reason is that the level of oil in the crankcase

will vary greatly the amount of lubrication received by the engine. A high

level results in excess lubrication and oil consumption and a slightly low

level results in inadequate lubrication and failure of the engine.

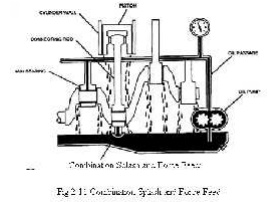

Combination

of Splash and Force Feed:

In a combination splash and force

feed , oil is delivered to some parts by means of splashing and other parts

through oil passages under pressure from the oil

pump. The oil from the pump enters the oil galleries.

From the

oil galleries, it

flows to the main

bearings and camshaft

bearings.

The main bearings have oil-feed holes or grooves that feed oil into drilled

passages in the crankshaft. The oil flows through these passages to the

connecting rod bearings. From there, on some engines, it flows through holes

drilled in the connecting rods to the piston- pin bearings. Cylinder walls are

lubricated by splashing oil thrown off from the connecting-rod bearings. Some

engines use small troughs under each connecting rod that are kept full by small

nozzles which deliver oil under pressure from the oil pump. These oil nozzles

deliver an increasingly heavy stream as speed increases.

At very

high speeds these oil streams are powerful enough to strike the

dippers directly. This

causes a much

heavier splash so

that adequate lubrication of the pistons and the connecting-rod bearings

is provided at higher speeds. If a combination system is used on an overhead

valve engine, the upper valve train is lubricated by pressure from the pump.

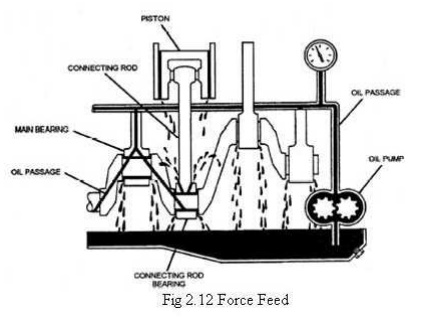

2.Force Feed :

A

somewhat more complete pressurization of lubrication is achieved in the force-

feed lubrication system. Oil is

forced by the oil pump from the crankcase to the main bearings and the camshaft

bearings. Unlike the combination system the connecting-rod bearings are also

fed oil under pressure from the pump. Oil passages are drilled in the crankshaft

to lead oil to the connecting-rod bearings.

The passages deliver oil from the

main bearing journals to the rod bearing journals. In some engines, these

opening are holes that line up once for every crankshaft revolution. In other

engines, there are annular grooves in the main bearings through which oil can

feed constantly into the hole in the crankshaft. The pressurized oil that

lubricates the connecting-rod bearings goes on to lubricate the pistons and

walls by squirting out through strategically drilled holes. This lubrication

system is used in virtually all engines that are equipped with semi floating

piston pins.

3.Full Force Feed:

In a full

force-feed lubrication system,

the main bearings,

rod bearings,

camshaft bearings, and the

complete valve mechanism are lubricated by oil under pressure. In addition, the

full force-feed lubrication system provides lubrication under pressure to the

pistons and the piston pins. This is accomplished by holes drilled the length

of the connecting rod, creating an oil passage from the connecting rod bearing

to the piston pin bearing. This passage not only feeds the piston pin bearings

but also provides lubrication for the pistons and cylinder walls. This system

is used in virtually all engines that are equipped with full-floating piston

pins.

Related Topics