Chapter: Mechanical and Electrical : Thermal Engineering : Internal Combustion Engines

Fuel Systems

FUEL

SYSTEMS

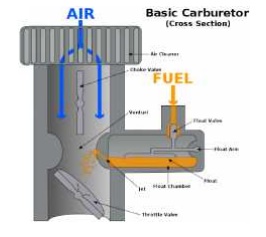

CARBURETOR

: (T.E R.K.R 598)

FUNCTION:

• A carburetor

is a device

that blends air and fuel for an internal combustion engine.

PRINCIPLE:

• The

carburetor worrks on Bernoulli's principle: the faster air mo ves, the lower

its static pressure, and the higher its dynamic pressure.

• The

throttle (accelerator) linkage does not directly control the flow of liquid

fuel. Instead, it actuates carburetor mechanisms which meter the flow of air

being pulled into the engine.

• The

speed of this fl ow, and therefore its pressure, determines the a mount of fuel

drawn into the airstream.

• When

carburetors are used in aircraft with piston engines, speci al designs and

features are needed to prevent fuel starvation during inverted flight. Later en

gines used an early form of fuel injection kn own as a pressure carburetor.

FUEL INJECTION: (A.E K.S

294-295)

Ø Fuel

injection is a system for admitting fuel into an internal combustio n engine.

Ø It has

become the prim ary fuel delivery system used in automotive en gines.

Ø The

primary differe nce between carburetors and fuel injection is that fuel injection atomizes the fuel by forcibly pumping it through a

small nozz le under high pressure, while a carburetor relies on suction created

by intake air accele rated through aVenturi tube to draw the fuel into the

airstream.

Ø Fuel is

transported from the fuel tank (via fuel lines) and pressuri sed using fuel pump(s). Maintaining the corr ect fuel pressure is done by a

fuel pressure regulator.

Ø Often a fuel rail is u sed to divide the fuel supply into the

requir ed number of cylinders.

The fuel injector injects liquid fuel into the intake air.

FUEL INJECTOR

Ø When

signalled by the engine control unit the fuel injector opens and sprays the

pressurised fuel into the engine.

Ø The

duration that the injector is open (called the pulse width) is proportional to

the amount of fuel delivered.

Ø Depending

on the system design, the timing of when injector opens is either relative each

individual cylinder (for a sequential fuel injection system), or injectors for

multiple cylinders may be signalled to open at the same time (in a batch fire

system).

Direct

injection

Ø In a

direct injection engine, fuel is injected into the combustion chamber as

opposed to injection before the intake valve (petrol engine) or a separate

pre-combustion chamber (diesel engine).

Ø Direct

fuel injection costs more than indirect injection systems: the injectors are

exposed to more heat and pressure, so more costly materials and

higher-precision electronic management systems are required.

Multiport

fuel injection

Ø Multiport

fuel injection injects fuel into the intake ports just upstream of each

cylinder's intake valve, rather than at a central point within an intake

manifold.

Ø The intake is only slightly wet, and typical fuel pressure runs between 40-60 psi.

Related Topics