Chapter: Mechanical and Electrical : Thermal Engineering : Internal Combustion Engines

Ignition System

IGNITION SYSTEM

Basically Convectional Ignition systems are of 2 types : (a) Battery or Coil Ignition System, and (b) Magneto Ignition System. Both these conventional, ignition systems work on mutual electromagnetic induction principle. Battery ignition system was generally used in 4-wheelers, but now-a-days it is more commonly used in 2-wheelers also (i.e. Button start, 2- wheelers like Pulsar, Kinetic Honda; Honda-Activa, Scooty, Fiero, etc.). In this case 6 V or 12 V batteries will supply necessary current in the primary winding. Magneto ignition system is mainly used in 2-wheelers, kick start engines. (Example, Bajaj Scooters, Boxer, Victor, Splendor, Passion, etc.). In

this case magneto will produce and supply current to the

primary winding. So in magneto ignition system magneto replaces the battery. Battery

or Coil Ignition System

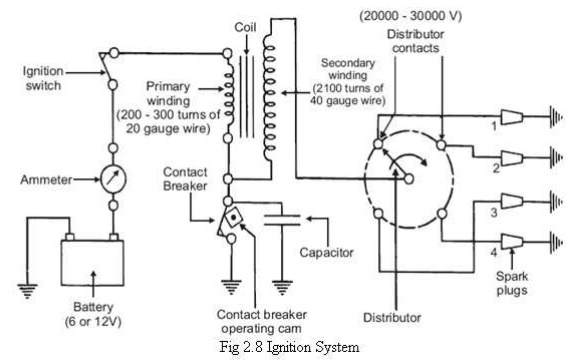

Figure

shows line diagram of battery ignition system for a 4-cylinder petrol engine.

It mainly consists of a 6 or 12 volt battery,

ammeter, ignition switch, auto-transformer (step up transformer), contact

breaker, capacitor, distributor rotor, distributor contact points, spark plugs,

etc. Note that the Figure 4.1 shows the ignition system for 4-cylinder petrol

engine, here there are 4-spark plugs and contact breaker cam has 4-corners. (If

it is for 6-cylinder engine it will have 6-spark plugs and contact breaker cam

will be a hexagon).

The ignition system is divided into 2-circuits: i.

Primary Circuit :

a. It consists of 6 or 12 V battery, ammeter, ignition switch,

primary winding it has

200-300

turns of 20 SWG (Sharps Wire Gauge) gauge wire, contact breaker, capacitor.

(ii) Secondary Circuit:

It consists of secondary winding.

Secondary Ignition Systems winding consists of about 21000 turns of 40

(S WG) gauge wire. Bottom end of which is connected to bottom end of primary

and top end of secondary winding is connected to centre of distributor rotor.

Distributor rotors rotate and make contacts with contact points and are

connected to spark plugs which are fitted in cylinder heads (engine earth).

(iii) Working : When the

ignition switch is closed and engine in cranked, as soon as the contact breaker

closes, a low voltage current will flow through the primary winding. It is also

to be noted that the contact beaker cam opens and closes the circuit 4-times

(for 4 cylinders) in one revolution. When the contact breaker opens the

contact, the magnetic field begins to collapse. Because of this collapsing

magnetic field, current will be induced in the secondary winding. And because

of more turns (@ 21000 turns) of secondary, voltage goes unto 28000-30000 volts.

This high voltage current is brought to centre of the distributor rotor.

Distributor rotor rotates and supplies this high voltage current to proper

stark plug depending upon the engine firing order. When the high voltage

current jumps the spark plug gap, it produces the spark and the charge is

ignited-combustion starts-products of combustion expand and produce power. Magneto

Ignition System In this case magneto will produce and supply the

required current to the primary winding. In this case as shown, we can

have rotating magneto with fixed coil or rotating coil with fixed magneto for

producing and supplying current to primary, remaining arrangement is same as

that of a battery ignition system.

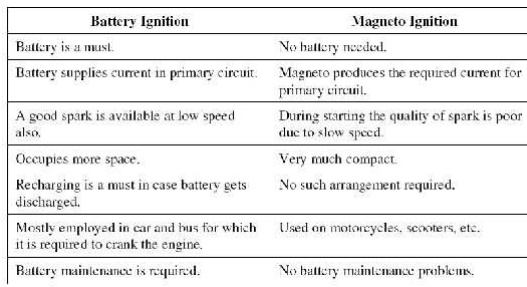

Comparison between Battery and Magneto Ignition

System:

Related Topics