Chapter: Mechanical : Metrology and Measurements : Linear and Angular Measurements

Linear Measuring Instruments

LINEAR MEASURING

INSTRUMENTS

Linear measurement applies to

measurement of lengths, diameter, heights and thickness including external and

internal measurements. The line measuring instruments have series of accurately

spaced lines marked on them e.g. Scale. The dimensions to be measured are

aligned with the graduations of the scale. Linear measuring instruments are

designed either for line measurements or end measurements. In end measuring

instruments, the measurement is taken between two end surfaces as in

micrometers, slip gauges etc.

The

instruments used for linear measurements can be classified as:

1. Direct

measuring instruments

2. Indirect

measuring instruments

The

Direct measuring instruments are of two types:

1. Graduated

2. Non

Graduated

The graduated instruments include rules,

vernier calipers, vernier height gauges, vernier depth gauges, micrometers,

dial indicators etc.

The non graduated instruments include

calipers, trammels, telescopic gauges, surface gauges, straight edges, wire

gauges, screw pitch gauges, radius gauges, thickness gauges, slip gauges etc.

They

can also be classified as

1. Non

precision instruments such as steel rule, calipers etc.,

2. Precision

measuring instruments, such as vernier instruments, micrometers, dial gauges

etc.

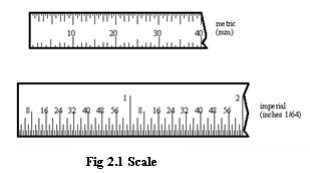

SCALES

·

The most common tool for crude

measurements is the scale (also known as rules, or rulers).

·

Although plastic, wood and other

materials are used for common scales, precision scales use tempered steel

alloys, with graduations scribed onto the surface.

·

These are limited by the human eye.

Basically they are used to compare two dimensions.

·

The metric scales use decimal divisions,

and the imperial scales use fractional divisions.

·

Some scales only use the fine scale

divisions at one end of the scale. It is advised that the end of the scale not

be used for measurement. This is because as they become worn with use, the end

of the scale will no longer be at a `zero' position.

·

Instead the internal divisions of the

scale should be used. Parallax error can be a factor when making measurements

with a scale.

CALIPERS

Caliper is an instrument used for

measuring distance between or over surfaces comparing dimensions of work pieces

with such standards as plug gauges, graduated rules etc. Calipers may be

difficult to use, and they require that the operator follow a few basic rules,

do not force them, they will bend easily, and invalidate measurements made. If

measurements are made using calipers for comparison, one operator should make

all of the measurements (this keeps the feel factor a minimal error source).

These instruments are very useful when dealing with hard to reach locations

that normal measuring instruments cannot reach. Obviously the added step in the

measurement will significantly decrease the accuracy.

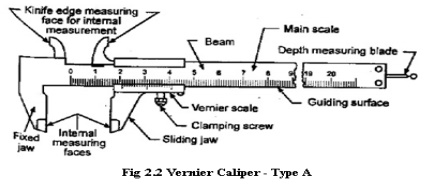

VERNIER CALIPERS

The vernier instruments generally used

in workshop and engineering metrology have comparatively low accuracy. The line

of measurement of such instruments does not coincide with the line of scale.

The accuracy therefore depends upon the straightness of the beam and the

squareness of the sliding jaw with respect to the beam. To ensure the

squareness, the sliding jaw must be clamped before taking the reading. The zero

error must also be taken into consideration. Instruments are now available with

a measuring range up to one meter with a scale value of 0.1 or 0.2 mm.

Types

of Vernier Calipers

According to Indian Standard IS:

3651-1974, three types of vernier calipers have been specified to make external

and internal measurements and are shown in figures respectively. All the three

types are made with one scale on the front of the beam for direct reading.

Type A: Vernier

has jaws on both sides for external and internal measurements and a

blade for depth measurement.

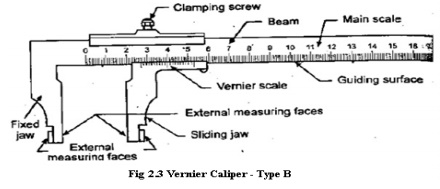

Type B: It

is provided with jaws on one side for external and internal measurements.

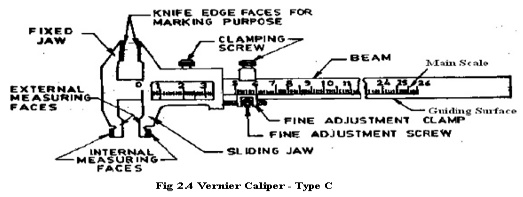

Type C: It has

jaws on both

sides for making

the measurement and

for marking

Operations

Errors

in Calipers

The degree of accuracy obtained in

measurement greatly depends upon the condition of the jaws of the calipers and

a special attention is needed before proceeding for the measurement. The

accuracy and natural wear, and warping of Vernier caliper jaws should be tested

frequently by closing them together tightly and setting them to 0-0 point of

the main and Vernier scales.

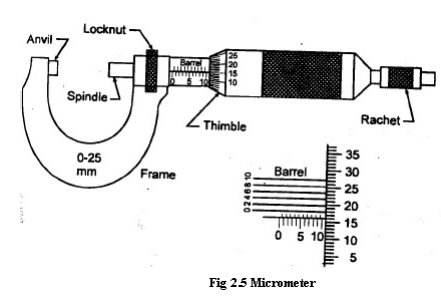

MICROMETERS

There

are two types in it.

(i) Outside

micrometer — To measure external dimensions.

(ii)

Inside micrometer — To measure internal

dimensions.

An outside micrometer is shown. It consists of two

scales, main scale and thimble scale. While the pitch of barrel screw is 0.5 mm

the thimble has graduation of 0.01 mm. The least count of this

micrometer is 0.01 mm.

The micrometer requires the use of an

accurate screw thread as a means of obtaining a measurement. The screw is

attached to a spindle and is turned by movement of a thimble or ratchet at the

end. The barrel, which is attached to the frame, acts as a nut to engage the

screw threads, which are accurately made with a pitch of 0.05mm. Each

revolution of the thimble advances the screw 0.05mm. On the barrel a datum line

is graduated with two sets of division marks.

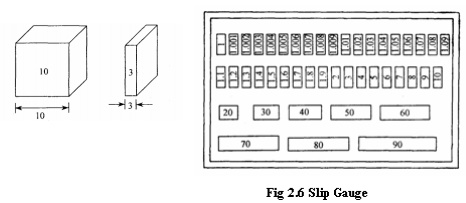

SLIP GAUGES

These may be used as reference standards for

transferring the dimension of the unit of length from the primary standard to

gauge blocks of lower accuracy and for the verification and graduation of

measuring apparatus. These are high carbon steel hardened, ground and lapped

rectangular blocks, having cross sectional area 0f 30 mm 10mm. Their opposite

faces are flat, parallel and are accurately the stated distance apart. The

opposite faces are of such a high degree of surface finish, that when the

blocks are pressed together with a slight twist by hand, they will wring

together. They will remain firmly attached to each other. They are supplied in

sets of 112 pieces down to 32 pieces. Due to properties of slip gauges, they

are built up by, wringing into combination which gives size, varying by steps

of 0.01 mm and the overall accuracy is of the order of 0.00025mm. Slip gauges

with three basic forms are commonly found, these are rectangular, square with

center hole, and square without center hole.

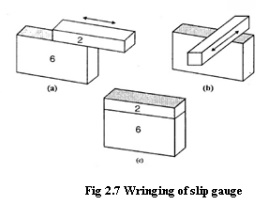

Wringing or Sliding is

nothing but combining the faces of slip gauges one over the other. Due

to adhesion property of slip gauges, they will stick together. This is because

of very high degree of surface finish of the measuring faces.

Classification of Slip Gauges

Slip

gauges are classified into various types according to their use as follows:

1) Grade

2

2) Grade

1

3) Grade

0

4) Grade

00

5) Calibration

grade.

1) Grade

2:

It is a workshop grade slip gauges used

for setting tools, cutters and checking dimensions roughly.

2)

Grade 1:

The

grade I is used for precise work in tool rooms.

3)

Grade 0:

It

is used as inspection grade of slip gauges mainly by inspection department.

4)

Grade 00:

Grade 00 mainly used in high precision

works in the form of error detection in instruments.

5)

Calibration grade:

The actual size of the slip gauge is

calibrated on a chart supplied by the manufactures.

Manufacture

of Slip Gauges

The following additional operations are

carried out to obtain the necessary qualities in slip gauges during

manufacture.

i. First

the approximate size of slip gauges is done by preliminary operations.

ii. The

blocks are hardened and wear resistant by a special heat treatment process.

iii. To

stabilize the whole life of blocks, seasoning process is done.

iv. The

approximate required dimension is done by a final grinding process..

v. To

get the exact size of slip gauges, lapping operation is done.

vi.Comparison

is made with grand master sets.

Slip

Gauges accessories

The application slip gauges can be

increased by providing accessories to the slip gauges. The various accessories

are

· Measuring

jaw

· Scriber

and Centre point.

· Holder

and base

1. Measuring

jaw:

It

is available in two designs specially made for internal and external features.

2.

Scriber and Centre point:

It

is mainly formed for marking purpose.

3.

Holder and base:

Holder is nothing but a holding device

used to hold combination of slip gauges. Base in designed for mounting the

holder rigidly on its top surface.

Related Topics