Chapter: Mechanical : Metrology and Measurements : Linear and Angular Measurements

Snap Gauge and its types

SNAP

GAUGE

Snap

gauges are used for checking external dimensions. They are also called as gap

gauges.

The different types of snap gauges are:

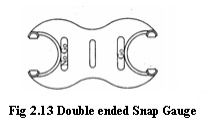

1. Double Ended Snap Gauge

This gauge is having

two ends in the form of anvils. Here also, the GO anvil is made to lower limit

and NOGO anvil is made to upper limit of the shaft. It is also known as solid

snap gauges

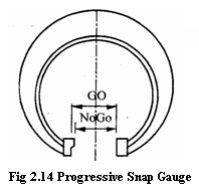

2. Progressive Snap Gauge

This type of snap gauge

is also called caliper gauge. It is mainly used for checking large diameters up

to 100mm. Both GO and NOGO anvils at the same end. The GO anvil should be at

the front and NOGO anvil at the rear. So, the diameter of the shaft is checked

progressively by these two ends. This type of gauge is made of horse shoe

shaped frame with I section to reduce the weight of the snap gauges.

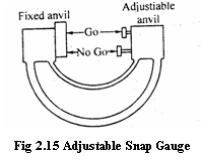

3. Adjustable Snap Gauge

Adjustable snap gauges

are used for checking large size shafts made with horseshoe shaped frame of I

section. It has one fixed anvil and two small adjustable anvils. The distance

between the two anvils is adjusted by adjusting the adjustable anvils by means

of setscrews. This adjustment can be made with the help of slip gauges for

specified limits of size.

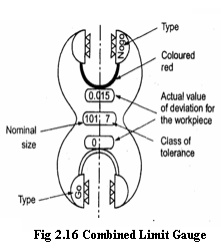

4. Combined Limit Gauges

A spherical projection

is provided with GO and NOGO dimension marked in a single gauge. While using GO

gauge the handle is parallel to axes of the hole and normal to axes for NOGO

gauge.

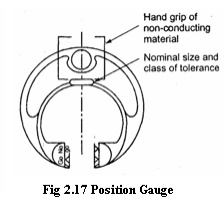

5. Position Gauge

It is designed for

checking the position of features in relation to another surface. Other types

of gauges are also available such as contour gauges, receiver gauges, profile

gauges etc.

Related Topics