Chapter: Mechanical : Metrology and Measurements : Linear and Angular Measurements

Bevel protractors

BEVEL PROTRACTORS

Bevel

protractors are nothing but angular measuring instruments.

Types

of bevel protractors:

The different types of

bevel protractors used are:

1) Vernier

bevel protractor

2) Universal

protractor

3) Optical

protractor

VERNIER BEVEL

PROTRACTOR:

Working principle

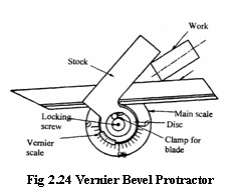

A vernier bevel

protractor is attached with acute angle attachment. The body is designed its

back is flat and no projections beyond its back. The base plate is attached to

the main body and an adjustable blade is

attached to the

circular plate containing Vernier scale. The main scale is graduated in degrees

from 0┬░ to 90┬░ in both the directions. The adjustable can be made to rotate

freely about the center of the main scale and it can be locked at any position.

For measuring acute angle, a special attachment is provided. The base plate is

made fiat for measuring angles and can be moved throughout its length. The ends

of the blade are beveled at angles of 45┬░ and 60┬░. The main scale is graduated

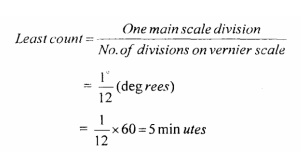

as one main scale division is 1┬░ and Vernier is graduated into 12 divisions on

each side of zero. Therefore the least count is calculated as

Thus, the bevel

protractor can be used to measure to an accuracy of 5 minutes.

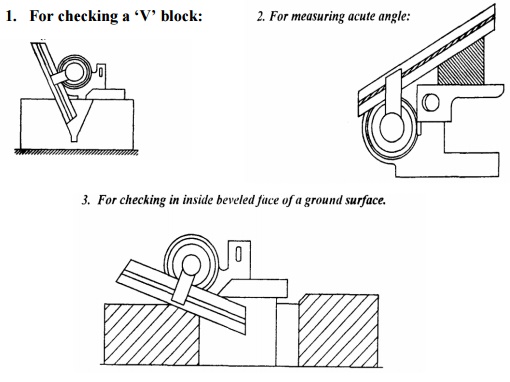

Applications of bevel protractor

The bevel protractor can be used in the following

applications.

AUTO- COLLIMATOR

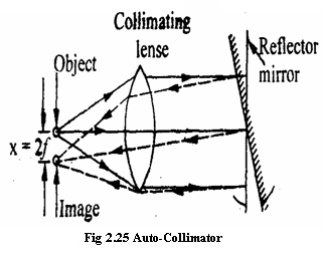

Auto-collimator is an

optical instrument used for the measurement of small angular differences,

changes or deflection, plane surface inspection etc. For small angular

measurements, autocollimator provides a very sensitive and accurate approach.

An auto-collimator is essentially an infinity telescope and a collimator

combined into one instrument.

Basic

principle

If a light source is

placed in the flows of a collimating lens, it is projected as a parallel beam

of light. If this beam is made to strike a plane reflector, kept normal to the

optical axis, it is reflected back along its own path and is brought to the

same focus. The reflector is tilted through a small angle ŌĆś0ŌĆÖ. Then

beam the is deflected parallel twice the angle and is brought to focus in the same

plane as the light source.

The distance of focus

from the object is given by

WORKING

OF AUTO-COLLIMATOR:

There

are three main parts in auto-collimator.

1. Micrometer

microscope.

2. Lighting

unit and

3. Collimating

lens.

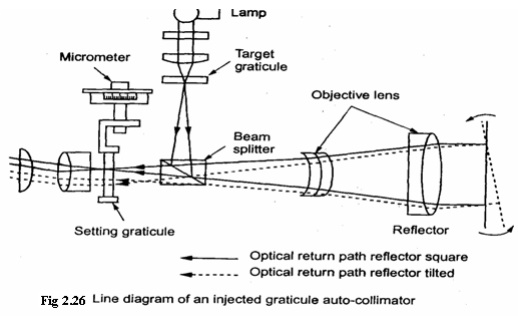

Figure shows a line

diagram of a modern auto-collimator. A target graticule is positioned

perpendicular to the optical axis. When the target graticule is illuminated by

a lamp, rays of light diverging from the intersection point reach the objective

lens via beam splitter. From objective, the light rays are projected as a

parallel rays to the reflector.

A flat reflector placed in front of the objective

and exactly normal to the optical axis reflects the parallel rays of light back

along their original paths. They are then brought to the target graticule and

exactly coincide with its intersection. A portion of the returned light passes

through the beam splitter and is visible through the eyepiece. If the reflector

is tilted through a small angle, the reflected beam will be changed its path at

twice the angle. It can also be brought to target graticule but linearly

displaced from the actual target by the amount 2╬Ėx

f. linear displacement of the graticule image in the plane tilted angle of

eyepiece is directly proportional to the reflector. This can be measured by

optical micrometer. The photoelectric auto- collimator is particularly suitable

for calibrating polygons, for checking angular indexing and for checking small

linear displacements.

APPLICATIONS

OF AUTO-COLLIMATOR

Auto-collimators

are used for

1) Measuring

the difference in height of length standards.

2) Checking

the flatness and straightness of surfaces.

3) Checking

square ness of two surfaces.

4) Precise

angular indexing in conjunction with polygons.

5) Checking

alignment or parallelism.

6) Comparative

measurement using master angles.

7) Measurement

of small linear dimensions.

8) For

machine tool adjustment testing.

Related Topics