Chapter: Mechanical : Metrology and Measurements : Linear and Angular Measurements

Sine bar

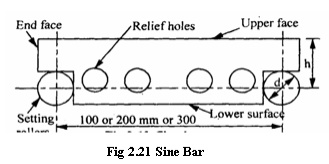

SINE BAR

Sine bars are always used along with

slip gauges as a device for the measurement of angles very precisely. They are

used to

1) Measure

angles very accurately.

2) Locate

the work piece to a given angle with very high precision.

Generally, sine bars

are made from high carbon, high chromium, and corrosion resistant steel. These

materials are highly hardened, ground and stabilized. In sine bars, two

cylinders of equal diameter are attached at lie ends with its axes are mutually

parallel to each other. They are also at equal distance from the upper surface

of the sine bar mostly the distance between the axes of two cylinders is 100mm,

200mm or 300mm. The working surfaces of the rollers are finished to 0.2┬Ąm

R value. The cylindrical holes are provided to reduce the weight of the sine

bar.

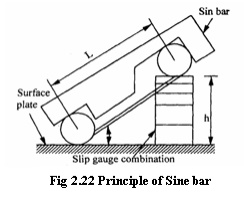

Working principle of

sine bar

The working of sine bar

is based on trigonometry principle. To measure the angle of a given

specimen, one roller of the sine bar is placed on the surface plate and another

one roller is placed over the surface of slip gauges. Now, ŌĆśh be the he slip

gauges and ŌĆśLŌĆÖ becenters,thenthe angledistancecalculatedas between

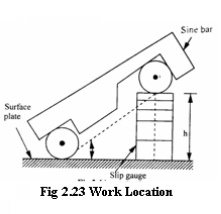

Use of Sine Bar

Locating anyŌĆÖ

work to a

given angle

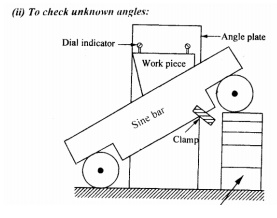

1) Before checking the unknown angle of the

specimen, first the angle (0) of given specimen is found approximately by bevel

protractor.

2) Then

the sine bar

is set at

angle of 0

and clamped on the angle plate.

3) Now, the work is placed on the sine bar

and the dial indicator set at one end of the work is moved across the work

piece and deviation is noted.

4) Slip gauges are adjusted so that the dial

indicator reads zero throughout the work surface.

Limitations

of sine bars

1) Sine

bars are fairly reliable for angles than 15┬░.

2) It

is physically difficult to hold in position.

3) Slight

errors in sine bar cause larger angular errors.

4)

A difference of deformation occurs at

the point of roller contact with the surface plate and to the gauge blocks.

5) The

size of parts to be inspected by sine bar is limited.

Sources

of error in sine bars

The

different sources of errors are listed below:

1) Error

in distance between roller centers.

2) Error

in slip gauge combination.

3) Error

in checking of parallelism.

4) Error

in parallelism of roller axes with each other.

5) Error in flatness of the upper surface of sine bar.

Related Topics