Chapter: Mechanical : Automobile Engineering : Engine Auxiliary Systems Ignition System

Introduction of Ignition System

Introduction of Ignition System

·

For petrol engine - Battery ignition system , Magneto ignition

system Injection system

·

For diesel engine - Fuel supply system.

Battery

ignition system:

Battery

ignition system has the following

elements

·

Primary Ignition Circuit(low voltage)

·

Battery

·

Ignition switch

·

Primary windings of coil

·

Contact breaker

·

capacitor

·

Secondary Ignition Circuit ( high voltage)

·

Secondary windings of coil

·

Distributor cap and rotor (if the vehicle is so

equipped)

·

Spark plug wires &

·

Spark plugs

IGNITION SYSTEM – Magneto

System Ignition Switch Distribution Contact Breaker Coil Magneto Condenser

Power Generation Spark Generation Magneto Unit Rotor Arm

IGNITION SYSTEM –

Dynamo/Alternator System Dynamo/ Alternator Distributor Contact Breaker Coil

Ignition Switch Secondary Windings Primary Windings Condenser Battery

Ignition Switch Coil Packs IGNITION SYSTEM –

Electronic Systems Control Unit Timing Sensor Timing Disc Engine Speed Sensing

Unit Alternator Battery

In all spark ignition engines

which work on the Gasoline either 2-Stroke or 4-Stroke cycle principle and

utilize a carburetor or fuel injection system, the combustion of the air-fuel

mixture is initiated by an electric spark.

The term ‘Spark

Ignition’ means that a brief electric arc is produced between the electrodes of a

spark plug, the energy for which is derived from an external power source. In

most cases this power source is the vehicle battery, which is constantly being

supplemented by the alternate while the vehicle is mobile.

A different method of ignition is

employed in diesel engines. This is called ‘compression ignition’

and relies on the fact that when air compressed, its temperature rises. In

diesel engines,

compression ratio of between 16:1 and 25:1 are common, and at

the end of a compression the temperature of the trapped air is sufficiently

high to ignite the diesel fuel that is sprayed into the cylinder at the

appropriate time.

The functions of ignition system

The functions of the coil ignition systems in general use on

motor vehicle may be divided into three areas. These are:

·

Production of the high voltage necessary to

produce a spark at the plug gap.

·

Distribute the spark to all the cylinders at

proper time based on the firing order.

·

Varying the timing of the spark depending on the

various operating conditions of the engine like cranking time, varying speed

and load, so that the best performance is obtained from the engine under all

operating conditions.

Mechanism of Ignition

It must be remembered that vehicle battery voltages are

usually 12 volt or 24 volt and this value is too low to produce a heavy spark

at the plug gap in a cylinder under compression. For this reason one of the

major functions of the battery ignition system is to raise the battery voltage

to the required level and then apply it to spark plugs.

This process is correctly initiated in the primary circuit and

completed in the secondary winding of the ignition coil. Depending on the type

of engine and the conditions existing in the cylinders, a voltage of between

5,000 to 20,000 volts is required and this is called the ionizing voltage

or firing voltage.

This firing voltage forces the electrons to jump between the

electrodes of the spark plug in the gap to produce the required spark. The

electric spark has sufficient heat energy to ignite the air-fuel mixture which

later continues to burn itself.

The conventional coil ignition

system

Inductive ignition systems: that uses an ignition coil

to perform the step up transformer action and to increase the electrical

voltage. The ignition coils of the inductive ignition systems operate on the

principle of electromagnetic induction (EMI) irrespective of whether it is

triggered by contact breakers or by electronic triggering units.

Note:

As a reminder of the principle of EMI, a voltage will be

induced into a coil whenever the following factors are present:

(a)

a magnetic field

(b)

a set of conductors

(c)

a relative movement between the magnetic field and

conductors.

The

factors affecting the operation of the Ignition system.

` The factors that determine the value of the

voltages induced into the ignition coil windings during the ignition cycle are:

(a) The

strength of the magnetic field.

The stronger the magnetic field produced in the

coil primary winding, the greater the possibility of producing a high secondary

voltage.

(b)

The number of conductors on the secondary winding

being cut by the magnetic field. This

isimportant when considering the

voltages produced in both coil windings during the ignition cycle.

(c) The speed

of relative movement between the magnetic field and the conductors. The faster

the magnetic field can be made to cut the conductors, the higher will be the

value of voltage induced into the coil windings.

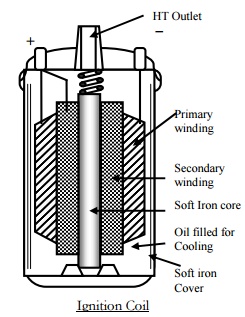

Construction

of the Ignition coil

The source of the high voltage pulses of current produced in

the inductive ignition system is in the ignition coil. The coil stores the

energy in the magnetic field around the primary winding and at the required

instant of ignition, transforms it into a pulse of high voltage current in the

secondary

winding. From here it is delivered to the correct

spark plug via the high tension (HT) cables.

This

‘Inductive

storage device’ may vary in design between certain manufacturers, but in

general the most common construction is as shown in figure below.

This

coil contains a rod shaped, laminated soft iron core at its centre, and the

soft iron cover surrounds both primary and secondary windings. Both of these

soft iron components are used to intensify and maximize the effect of the

primary magnetic field and thus, the energy stored. The iron core must be

laminated to minimize the effects of eddy currents that are produced during

operation and so keep to a minimum the heat developed. The outer soft iron cover

is slotted to allow circulation of the oil filling which is used for cooling

purposes.

Around the laminated core, the secondary winding is wounded.

This consists of many turns of very fine insulated copper wire (generally in

the vicinity of 20,000 turns). One end of this winding is connected to the HT

outlet of the coil via the laminated iron core which it used as the pick-up

point for this connection. The other end is connected to the positive (+) low

tension primary terminal.

Over the top of the secondary winding the primary winding is

wounded with the insulation. The primary winding consisting of a few hundred

turns of relatively heavy insulated copper wire. The ends of the primary

winding are connected to the two low tension, or primary terminals. A reason

for placing the primary winding over the secondary is that it is in this coil,

which caries the full primary circuit current (approximately 2 ampere in

standard systems), the secondary winding generates the heat and by placing it

thus, the cooling oil is given ready access to it.

A ceramic insulator at the base of the coil supports the core

and winding and at the top is a plastic-type insulator which provides a

location point for the high-tension and primary terminals. This top insulator

is sealed into the outer case to prevent the loss of coolant oil or the energy

of moisture.

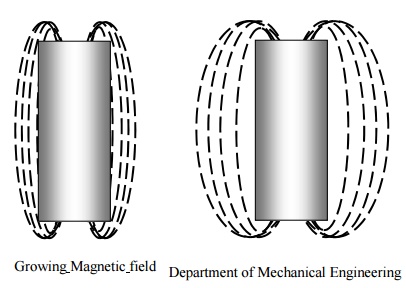

Operation of an Ignition coil

Electromagnetic induction is the effect of creating the

voltage in a conductor by means of relative movement between the conductor and

a magnetic field. In the ignition coil the conductors remain stationary and the

magnetic field is moved across them. To develop these necessary conditions, the

first requirement in the ignition oil is the production of a magnetic field.

This is the function of the primary winding.

When

the ignition switch is closed, the primary winding of the coil is connected to

the positive terminal of the vehicle battery. Now, if the primary circuit is

completed through the contact breaker points a current will flow in the

circuit, creating a magnetic field in the coil around the soft iron core. This

magnetic field grows outwards from the core until it has reached maximum value

and the core is fully magnetized and ceases to grow further.

To provide the very high voltage necessary to create a spark

across the plug gap, the secondary winding has a very large number of turns.

NOTE: The ratio of the number of secondary turns to the number of primary turns

is very large – approximately 100:1. The effect of this high

ration is to produce a very high voltage in the secondary winding when the

magnetic field is collapsed rapidly across it as the contact breaker points are

opened.

To understand the operation of the ignition coil, it is

necessary to have the knowledge of the effect of winding insulated wire into

the form of a coil and then passing a current through it. In earlier chapters

of this course, an explanation was given of how a magnetic field forms around a

wire when current flows through it.

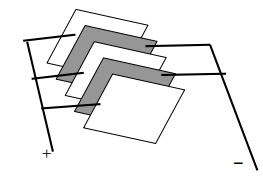

Construction

The

construction of a capacitor is quite simple. It is made of two strips of

metallised paper, separated by a thin dielectric (insulator), generally of

waxed paper or plastic, both rolled tightly together and fitted into a metal

container. An insulated flexible lead is attached to one of the metallised

plates and brought out for connection to the insulated side of the contacts.

The other metallised plate is attached to the metal container which has

facilities for connecting it to a good earth either inside or outside the

distributor, thus effectively connecting the capacitor across, or in parallel,

with the points.

As

a general statement it can be said that a capacitor is a device which has

the ability to store an electrical

charge. When a capacitor is

‘charged’, each plate will hold an equal

but opposite charge. That is the

plate connected to

the negative side

of the circuit

will acquire a negative charge,

and the plate connected to the positive side of the circuit, a positive

charge. Once these opposite charges are

stored on the plates, they will attract each other through the separating

dielectric, and thus tend to prevent the charge escaping or leaking away.

NOTE:

The loss of electrical charge from a capacitor is termed the capacitor’s

leakage. Among the tests applied to a capacitor is a test for

leakage, which must be below a certain rate of loss.

Removing

the charge from a capacitor is called discharging it. This is accomplished by

connecting a conductor across its plates. The excess electrons are attracted

from the negatively charged plate to the positively electrons are attracted

from the negatively charged plate to the positively charged plate. The electron

flow continues until such time as both charges equalize, i.e. there is no

potential difference between the plates.

The

factors affecting the capacity of a capacitor:

(a)

The area of the plates holding the charges and the

number of plates used.

(b)

The distance the plates are separated, i.e. the

thinner the dielectric, the greater the attractive force between the charges,

and therefore the higher the capacity.

(c)

The type of dielectric, e.g. plastic, mica, paper,

air, etc.

Unit

of Capacitor

The amount of charge a capacitor

can hold is termed its capacitance (symbol C) which is measured in a unit

called the farad (symbol F). Since the farad is a large quantity and it is

difficult to have such a big capacitor in real time, the capacitors are generally

measured by micro farad (Symbol µF)

Automotive capacitors are in the

vicinity of 0.20 to 0.30 microfarads (one microfarad = 10-6 farads,

or 1 millionth of a farad).

The

operation of a capacitor in an ignition circuit is relatively simple, but tends

to appear complex because of the number of events, or changes, that occur

simultaneously. The following explanation presents these changes as a logical,

sequential set of events.

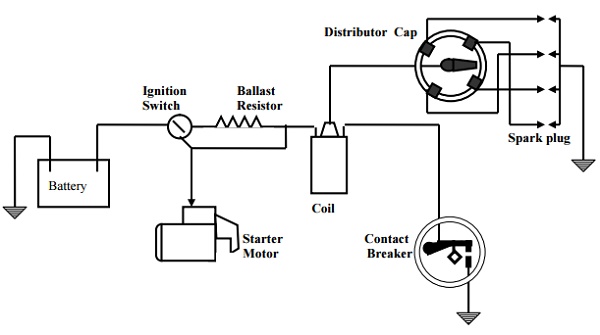

CIRCUIT

OF THE IGNITION CIRCUIT

A simple circuit shown above can illustrate the position of

the major components of an ignition system. With the

ignition switch ‘on’: when the breaker contacts initially close, a

current

commences

to flow in the primary circuit and the magnetic field builds up relatively

slowly, due to the self induced voltage that is developed at this time

During this ‘closed circuit period’ of the ignition

cycle, the capacitor is in parallel with the

breaker

contacts which are closed at this time. As the distributor shaft continues its

rotation the cam lobe lift the breaker gently to open the contacts.

It takes a certain number of degrees of distributor shaft

rotation and therefore a measurable period of time for this to occur.

When the contacts are open and instantly a resistance is

presented to the primary circuit because of this contact gap. The primary

current is interrupted and the magnetic field is starting to collapse. The

current produced by the self induced voltage has to enter the plates of the

capacitor. Since the high resistance will be induced across the contacts due to

their separation and it will naturally take the low resistance path.

Capacitor function

When the contacts gap is slowly widening and the self induced

voltage is rapidly rising towards the 200-300 volt level. The capacitor is

rapidly charging up. As the capacitor reaches the

fully

charged state, the contacts have opened to such a degree that even this high

voltage cannot jump the gap and so the primary circuit

currents comes to an ‘instant halt’.

This sudden stopping of the primary current, produced by the

action of the capacitor, gives an extremely fast collapse of the magnetic

field. The mutually induced voltage, generated in the secondary winding at this

instant will be very high. Since the secondary winding has about 100 times as

many turns as the primary winding, the secondary voltage will be about 100

times higher than the primary voltage (200 to 300 volts).

The

secondary voltage at this instant is fed out through the HT circuit to the

correct spark plug where it ionizes the plug gap and forms a spark which

ignites the air-fuel mixture. For the period of time of spark duration the

capacitor remains fully charged. After the energy of the secondary circuit has

been expended in the HT spark, the capacitor discharges back through the

battery, ignition switch and coil primary to the opposite plate of the

capacitor, thus recharging it in the reverse direction. The capacitor then

discharges back again to recharge itself in the original direction – but at a

lower value. It continues this oscillating cycle of charge and discharge until

all of the stored energy is dissipated across the resistance of the primary

circuit. The distributor cam continues its rotation, the points close again and

the whole cycle is repeated.

Related Topics