Chapter: Mechanical : Automobile Engineering : Engine Auxiliary Systems Ignition System

Fuel Injection system for C I engines

Fuel Injection system for C I

engines

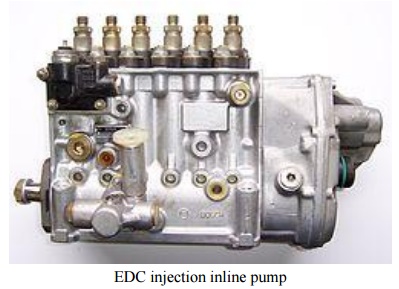

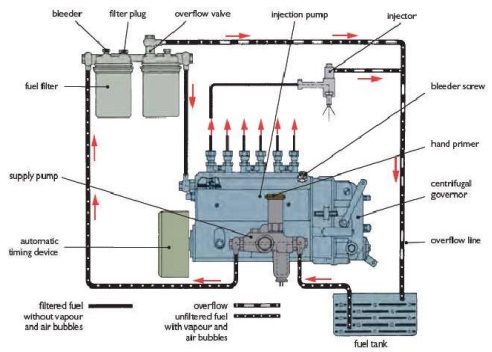

Fuel system components FUEL INJECTION PUMP - Fuel injection

pump sucks fuel from the tank , pressurizes the fuel to approx. 600 - 1000 bar

and sends it to the injectors. Inline FIP - Has separate pumping chambers for

each cylinder Rotary FIP (Distributor pump) - Has one pumping chamber and the

pump distributes to each cylinder as per sequence- firing order INJECTORS -

Inject the high pressure fuel in to each cylinder. FUEL FILTER - Filters the

fuel from dirt & sediments, since the Fuel injection pump requires clean

fuel.

Injection system In the C.I. engine the fuel is injected into

the combustion chamber, it the has to mix thoroughly with the air, ignite and

burn all at the same time. To insure this happens, two types of combustion

chamber have been developed. Direct Injection Indirect Injection

1. Electronic Diesel Control

Electronic Diesel Control

is a diesel engine fuel injection control system for the precise of metering

and delivery in fuel into the combustion chamber of modern diesel engines used trucks

and cars.

The mechanical fly-weight governors of inline and distributor diesel fuel

injection

pumps used to control fuel delivery under a variety of engine loads and

conditions could no longer deal with the ever increasing demands for

efficiency, emission control, power and fuel consumption.

These demands are now primarily fulfilled by the Electronic

Control, the system which provides greater ability for precise measuring, data

processing, operating environment flexibility and analysis to ensure efficient

diesel engine operation. The EDC replaces the mechanical control governor with

an electro-magnetic control device.

2. Components in Electronically

controlled Diesel Supply;

The

EDC is divided into these main groups of components.

· Electronic sensors for registering

operating conditions and

changes. A wide

array

of

physical inputs is converted into electrical signal outputs.

·

Actuators or solenoids which convert the control

unit's electrical output signal into mechanical control movement.

·

ECM (Electronic Control Module ) or Engine ECU

(Electronic Control Unit) with microprocessors which process information from

various sensors in accordance with programmed software and outputs required

electrical signals into actuators and solenoids.

i. Electronic sensors;

·

Injection pump speed sensor - monitors pump

rotational speed

·

Fuel rack position sensor - monitors pump fuel

rack position

·

Charge air pressure sensor - measures pressure

side of the turbocharger

·

Fuel pressure sensor

·

Air cleaner vacuum pressure sensor

·

Engine position sensor

·

Temperature sensors - measure various operating

temperatures

·

Intake temperature

·

Charge air temperature

·

Coolant temperature

·

Fuel temperature

·

Exhaust temperature (Pyrometer)

·

Ambient temperature

·

Vehicle speed sensor - monitors vehicle speed

·

Brake pedal sensor - operates with cruise control,

exhaust brake, idle control

·

Clutch pedal sensor - operates with cruise

control, exhaust brake, idle control

·

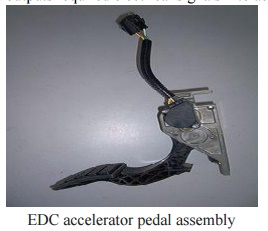

Accelerator pedal sensor.

ii.Electronic Control Unit;

The ECU collects and processes signals from various on-board

sensors. AnECU electronic module contains microprocessors, memory units, analog

to digital converters and output interface units. Depending upon the

parameters, a number of different maps can be stored in the onboard memory.

This allows the ECU to be tailored to the specific engine and

vehicle requirements, depending on the application. The operating software of

the ECU can be adapted for a wide variety of engines and vehicles without the

necessity of hardware modification.

The ECU is usually located in the

cab or in certain cases, in a suitable position in the engine bay where

additional environmental conditions might require cooling of the ECU as well as

a requirement for better dust, heatand vibrations insulation .

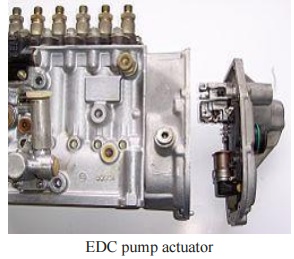

iii. Actuators and Solenoids

Electro-magnetic actuators are

usually located on the fuel pump to transfer electrical signals into mechanical

action in this case fuel rack actuator and or fuel stop solenoid which means

that depending on requests from control unit full fuel or no fuel quantity.

·

Injectors

·

Boost-pressure actuator

·

Intake-duct switchoff

·

Throttle-valve actuator

·

Exhaust-gas recirculation actuator

·

Auxiliary heating

·

A/C compressor

·

Radiator fan

·

Electronic shutoff valve

·

Rail-pressure control valve

·

Diagnosis lamp

Working Principle;

The injection of fuel or the quantity of injected fuel has a

decisive influence on engine starting, idling, power and emissions. The engine

ECU is programmed ("mapped") with relevant data to where the fuel

rack position has an equivalent signal for the amount of fuel being injected.

The driver requests the torque or engine speed requirements

via accelerator pedal potentiometer thereby sending a signal to the engine ECU

which then, depending on its mapping and data collected from various

sensors, calculates in real time the quantity of injected fuel required, thus

altering the fuel rack to the required position. The driver can also input

additional commands such as idle speed increase to compensate e.g. for PTO

operation which can be either variably set or has a preset speed which can be

recalled.

The road speed function can be used to evaluate

vehicle speed and possibly activate a speed limiter (Heavy Vehicles), or

maintain or restore a set speed (cruise control). Further functions can include

exhaust brake operation which, when activated, will result in the fuel pump

rack position being set to zero delivery or idle. The engine ECU can also

interface with various other vehicle systems e.g. traction control and carries

out self monitoring duties and self diagnostic functions to keep the system

working at an optimal level. To ensure the safe operation in case of failure,

the limp home mode functions are also integrated into the system, for e.g.

should the pump speed sensor fail the ECU can use an alternator speed signal

function for engine RPMs counter as a backup signal.

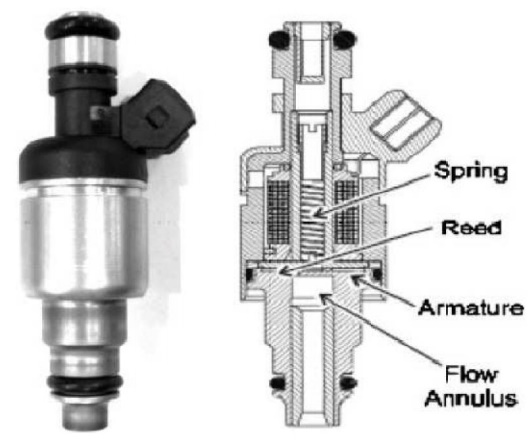

3. Fuel Injector:

Fuel injection is a system for admitting fuel into an internal

combustion engine. It has become the primary fuel delivery system used in

automotive engines, having replaced carburetors during the 1980s and 1990s. A

variety of injection systems have existed since the earliest usage of the

internal combustion engine.

The primary difference between carburetors and fuel injection

is that fuel injection atomizes the fuel by forcibly pumping it through a small

nozzle under high pressure, while a carburetor relies on suction created by

intake air accelerated through a Venturi tube to draw the fuel into the

airstream.

Modern fuel injection systems are designed

specifically for the type of fuel being used. Some systems are designed for

multiple grades of fuel (using sensors to adapt the tuning for the fuel

currently used). Most fuel injection systems are for gasoline or diesel

applications.

Related Topics