Chapter: Mechanical : Automobile Engineering : Engine Auxiliary Systems Ignition System

CRDI - Common rail fuel injection system

CRDI - Common rail fuel injection system

Common rail

direct fuel injection is a modern

variant of direct fuel injection system for petrol and diesel engines. On diesel engines,

it features a high-pressure (over 1,000 baror 100 MPa or 15,000 psi) fuel rail

feeding individual solenoid valves, as opposed to low-pressure fuel pump

feeding unit injectors (or pump nozzles). Third-generation common rail diesels

now feature piezoelectric injectors for increased precision, with fuel

pressures up to 3,000 bar (300 MPa; 44,000 psi). In gasoline engines, it is

used in gasoline direct injection engine technology.

Working Principle;

Solenoid or piezoelectric valves make possible fine electronic

control over the fuel injection time and quantity, and the higher pressure that

the common rail technology makes available provides better fuel atomisation. To

lower engine noise, the engine's electronic control unit can inject a small

amount of diesel just before the main injection event ("pilot" injection),

thus reducing its explosiveness and vibration, as well as optimising injection

timing and quantity for variations in fuel quality, cold starting and so on.

Some advanced common rail fuel systems perform as many as five injections per

stroke. Common rail engines require a very short (< 10 seconds) to no

heating-up time[ depending on ambient temperature, and produce lower

engine noise and emissions than older systemsDiesel engines have historically

used various forms of fuel injection. Two common types include the unit

injection system and the distributor/inline pump systems (See diesel engine

andunit injector for more information). While these older systems provided

accurate fuel quantity and injection timing control, they were limited by

several factors:

·

They were cam driven, and injection pressure was

proportional to engine speed. This typically meant that the highest injection

pressure could only be achieved at the highest engine speed and the maximum

achievable injection pressure decreased as engine speed decreased. This

relationship is true with all pumps, even those used on common rail systems.

With unit or distributor systems, the injection pressure is tied to the

instantaneous pressure of a single pumping event with no accumulator, and thus

the relationship is more prominent and troublesome.

·

They were limited in the number and timing of

injection events that could be commanded during a single combustion event.

While multiple injection events are possible with these older systems, it is

much more difficult and costly to achieve.

For the typical distributor/inline system, the start of

injection occurred at a pre-determined pressure (often referred to as: pop

pressure) and ended at a pre-determined pressure. This characteristic resulted

from "dummy" injectors in the cylinder head which opened and closed

at pressures determined by the spring preload applied to the plunger in the

injector. Once the pressure in the injector reached a pre-determined level, the

plunger would lift and injection would start.

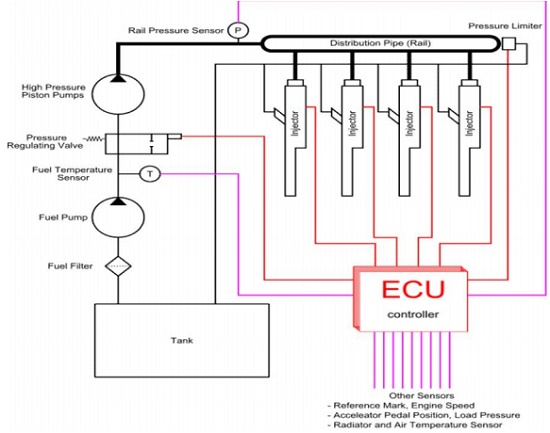

In common rail systems, a high-pressure pump stores a

reservoir of fuel at high pressure — up to

and above 2,000 bars (200 MPa; 29,000 psi). The term "common rail"

refers to the fact that all of the fuel injectors are supplied by a common fuel

rail which is nothing more than a pressure accumulator where the fuel is stored

at high pressure.

This accumulator supplies multiple fuel injectors with

high-pressure fuel. This simplifies the purpose of the high-pressure pump in

that it only needs to maintain a commanded pressure at a target (either

mechanically or electronically controlled). The fuel injectors are typically

ECU-controlled. When the fuel injectors are electrically activated, a hydraulic

valve (consisting of a nozzle and plunger) is mechanically or hydraulically

opened and fuel is sprayed into the cylinders at the desired pressure.

Since the fuel pressure energy is stored remotely and the

injectors are electrically actuated, the injection pressure at the start and

end of injection is very near the pressure in the accumulator (rail), thus

producing a square injection rate. If the accumulator, pump and plumbing are

sized properly, the injection pressure and rate will be the same for each of

the multiple injection events.

Related Topics