Chapter: Pharmaceutical Drug Analysis: Infrared Spectrophotometry

Infrared Spectrophotometry: Instrumentation

INSTRUMENTATION

The infrared spectrophotometers are based on either

single monochromation or double monochromation :

(a)

Single-Monochromator Infrared Spectrophotometer, and

(b) Double-Monochromator

Infrared Sepctrophotometer.

The optical diagrams, components used and their modes of

operation shall be discussed briefly in this context under different heads.

1. SINGLE MONOCHROMATOR INFRARED SPECTROPHOTOMETERS

The important features of an infrared spectrophotometer

are as follows :

(i) Infrared

sources,

(ii)

Monochromators,

(iii)

Detectors, and

(iv) Mode of

Operation.

1.1. Infrared Sources

The most common infrared sources are electrically heated

rods of the following types :

(a) Sintered

mixtures of the oxides of Zirconium (Zr), Yttrium (Y), Erbium (Er) etc., also

known as

‘Nernst Glower’,

(b) Silicon

Carbide ‘Globar’, and

(c) Various

ceramic (clay) materials.

It is quite evident that the infrared output from all

these different sources invariably varies in intensity over a definite

frequency range, therefore, a compensating variable slit is usually programmed

to operate in unison with the scanning over the individual frequencies.

1.2. Monochromators

Three types of substances are

normally employed as monochromators, namely :

(i) Metal Halide Prisms : Various metal

halide prisms, such as : KBr (12-25 μ m), LiF (0.2-6 μ m) and CeBr (15-38 μ m) have been used earlier, but they have become more or

less obsolescent nowadays.

(ii) NaCl Prism (2-15 μ m) : Sodium chloride prism are of

use for the whole of the region from 4000-650 cm–1. First, it offers

low resolution at 4000-2500 cm–1, and secondly, because of its

hygroscopic nature the optics have got to be protected at 20 °C above the

ambient temperature.

(iii) Gratings : In general, gratings are

commonly employed in the design of the instruments and offer better resolution

at higher frequency than the prisms. They offer much better resolution at low

frequency, viz., typical rulings are

240 lines per nm for the 4000-1500 cm–1 region and 120 lines per nm

for the 1500-650 cm–1 region.

1.3. Detectors

There are ion all three

different types of detectors that are used in the infrared region :

(a) Thermocouples (or Thermopiles) : The

underlying principle of a thermocouple is that if two dissimilar metal wires

are joined head to tail, then a difference in temperature between head and tail

causes a current to flow in the wires. In the infrared spectrophotometer this

current shall be directly proportional to the intensity of radiation falling on

the thermocouple. Hence, the thermo-couples are invariably employed in the

infrared region, and to help in the complete absorption of ‘available energy’

the ‘hot’ junction or receiver is normally blackened.

(b) Golay Detector : In this specific

instance the absorption of infrared radiation affords expansion of an inert gas

in a cell-chamber. One wall of the cell-chamber is provided with a flexible

mirror and the resulting distortion alters the intensity of illumination

falling on a photocell from a reflected beam of light. Thus, the current from

the photocell is directly proportional to the incident radiation.

(c) Bolometers : These are based on the

principle that make use of the increase in resistance of a metal with increase

in temperature. For instance, when the two platinum foils are appropriately

incorporated into a Wheatstone bridge, and radiation is allowed to fall on the

foil, a change in the resistance is observed ultimately. This causes an

out-of-balance current that is directly propor-tional to the incidental

radiation. Just like the thermocouples, they are used in the infrared region

1.4. Mode of Operation

The schematic layout of a single-monochromator infrared

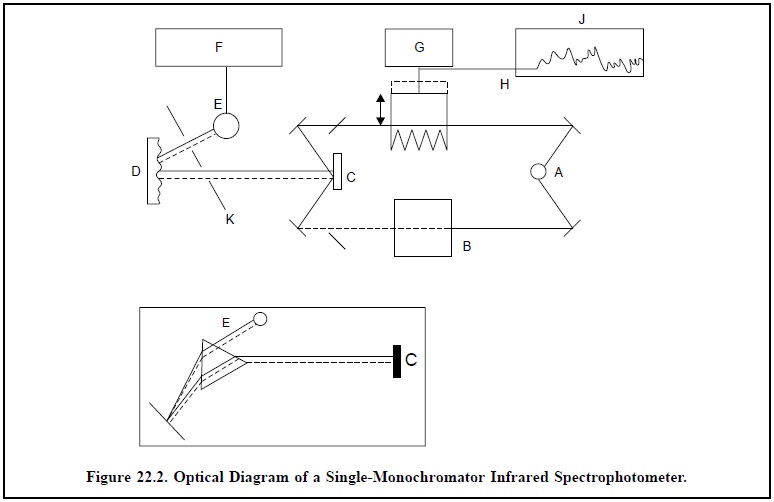

spectrophotometer has been duly depicted in Figure 22.2.

The various vital components of Figure 22.2 are as

follows :

A = Infrared source,

B = Sample beam,

C = Chopper—a rotating segmented mirror,

D = Monochromator grating,

E = Detector thermopile,

F = Amplifier,

G= Servo-motor,

H = An optical Wedge,

I= Prism,

J= Ink-pen recorder, and

K= Slits.

The sequential steps observed in the mode of operation

are as stated below :

(i) The light

from infrared source A is split equally into two beams ; one of which B is made

to pass through the sample i.e., the

sample beam while the other serves as reference beam.

The main objective of such a double beam operation is to

measure the difference in intensities between the two beams at each wave

length.

(ii) The two

beams are subsequently reflected on a rotating segmented mirror called chopper

C. The chopper rotating ≈ 10 times per second helps the

sample beam and the reference beam to be reflected alternatively to the

monochromator grating D.

(iii) Thus, the

grating rotates slowly and transmits individual frequencies to the detector

thermopile (E), that consequently converts the infrared (thermal) energy to the

corresponding electrical energy.

(iv) When a

sample has absorbed a certain quantum of light of specific frequency the

detector shall be receiving alternatively from the chopper an intense beam (due

to reference beam) and a relatively weak beam (due to sample beam). It will

generate a pulsating or alternating current (AC) flowing from the detector to

the amplifier F.

(v) This

out-of-balance signal received by the amplifier, is coupled to a small

servo-motor G, that drives an optical wedge (H) into the reference beam until

the detector receives light of equal intensity from sample and reference beams.

(vi) The

slightest movement of the wedge (or attenuator) is further coupled to a ink-pen

recorder J, so that movement of the former, both ‘in’ and ‘out’ of the

reference beam, is adequately recorded on the printed chart at various

absorption bands.

This specific type of the ‘double-beam optical-null recording spectrophotometer’ is termed so

because it critically balances out by the help of optical means the

differential between the two beams.

The ‘inset diagram’ in Figure 22.2 shows the use of a ‘prism’ in place of the ‘grating’. However, underlying

principle being identical, a rotating mirror affords the scanning of individual

frequencies.

2. DOUBLE-MONOCHROMATOR INFRARED SPECTROPHOTOMETER

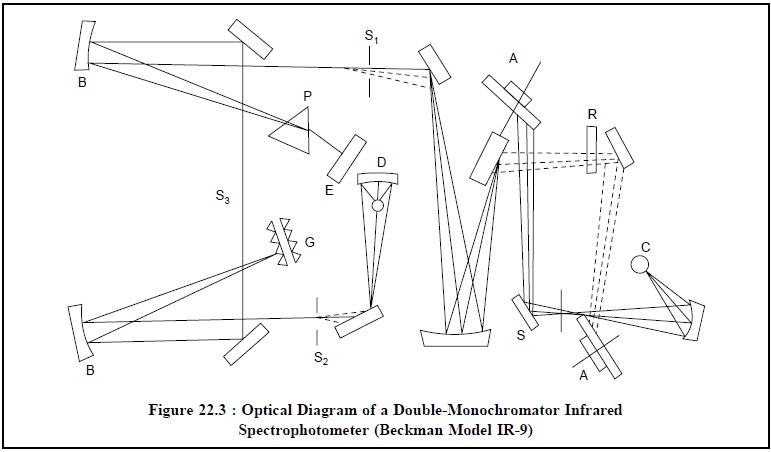

The schematic optical diagram of a double-beam infrared

spectrophotometer has been shown in Fig-ure 22.3 as per Beckman Model IR-9.

The various components of a double-monochromator infrared

spectrophotometer shown in Figure 22.3 are as follows below :

A = Rotating mirror,

B = Collimating mirror,

C = Infrared source,

S = Sample beam,

R = Reference beam,

D = Detector,

S1 = Entrance, slit,

S2 = Exit slit,

S3 = Intermediate slit,

E = Littrow mirror,

G = Monochromator Gratings, and

P = Prism.

The various steps that may be followed sequentially to

operate a double-monochromator infrared spectrophotometer are described below :

(i) The light

from the infrared source C is made to split into two beams one of which passes

through the sample (i.e., the sample

beam) while the other caters as the reference beam. This sort of dou-ble-beam

arrangement facilitates in measuring difference in intensities between the two beams at each wavelength,

(ii) In this

instance two monochromators have been employed in series with an intermediate

slit (S3) as shown in Figure 22.3,

(iii) The

optical train affords as much as twice the dispersion and the ultimate

resolution is fairly comparable to any single-monochromator instrument (Figure

22.2),

(iv) All stray

radiant energy is virtually eliminated,

(v) In Figure

22.3, (Beckman Model IR-9) one of the two prism monochromators has been

replaced with a dual grating, and

(vi) Finally,

the detector picks up light of equal intensity from sample and reference beams.

1.5. Experimental Profile of Infrared Spectroscopy : Quantitative Analysis

In usual practice, there are two methods that are frequently employed for the determination of

the transmittance ratio in quantitative analysis namely :

(a) Emperical

ratio method, and

(b) Base-line

method.

The above two

methods shall be discussed briefly with the help of certain typical examples as

detailed below :

1.5.1. Emperical Ratio Method

This particular method is often employed in a situation

where the absorption bands of the analyte are found to be very close to those

of the main constituent or the internal standard.

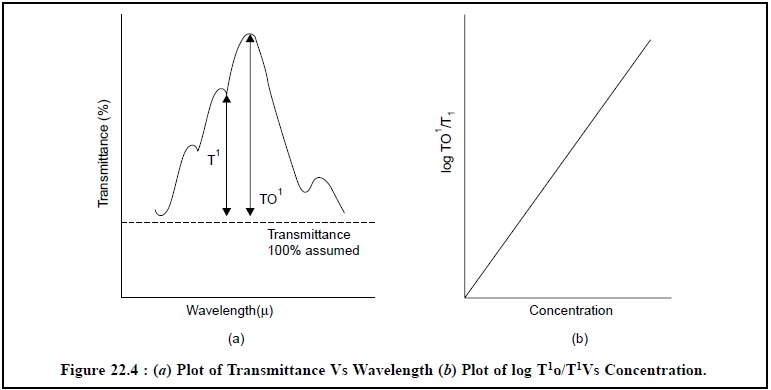

The quantitative analysis of pharmaceutical substances

may be achieved by emperical-ratio method either by plotting percentage

transmittance against wavelength or by plotting the log T1o/T1

against concen-tration as illustrated in Figure 22.4.

1.5.2. Base-Line Method

It essentially involves the selection of an absorption

band of an analyte which does not remain very close to the bands of other

constituents present in the matrix.

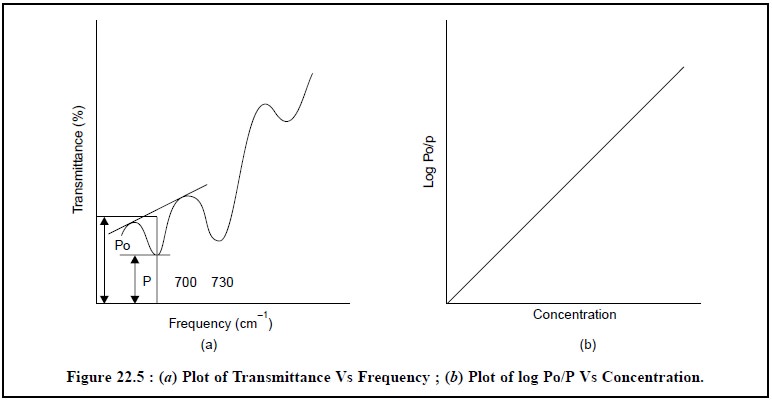

Figure 22.5 depicts the absorption bands of the sodium

salt of Penicillin G at 703 cm–1.

The value of the incident radiant energy Po may be

achieved by drawing a straight line tangent to the spectral absorption curve at

the position of the analyte’s absorption band. Consequently the transmittance P

is usually measured at the point of maximum absorption. Finally, the value of

log Po/P is plotted against the concentration as shown in Figure 22.5.

It is, however, pertinent to mention here that the

application of both emperical ratio method and base-line method help in

eliminating to a great extent the errors caused due to changes in source

intensity and adjustment of the optical system.

1.6. Determination of the Absorption Spectrum of a Solid Compound (or a Pharmaceu-tical Substance)

The determination of the absorption spectrum of a solid

pharmaceutical substance is invariably ac-complished by any one of the two following techniques namely :

(a) Mull

Technique, and

(b) Potassium

Bromide Disc Technique.

These two

different techniques shall be described below :

1.6.1. Mull Technique

Procedure : Take about 15-20 mg of sample

in a previously cleaned small agate mortar and powder it thoroughly (about 200 mesh). Add to it 2 drops of purified

paraffin (commonly known as Nujol) or any other suitable mulling liquid and

continue the trituration until a very smooth paste of uniform consistency is

achieved. Now, transfer the slurry to a sodium chloride window, placing it

carefully into the cavity made by the spacer. Consequently, place the other

window on top and thus assemble the cell. With the help of a clean piece of

tissue-paper wipe out the excess paste that has squeezed out from the cell

windows. Finally, intro-duce the cell in the respective cell-compartment.

Salient Features : The salient features of Mull

Technique are as follows :

(i) Particle

size of the sample has got to be reduced below 200 mesh or 3 μ m so as to avoid scattering of radiation thereby causing

poor absorption spectrum.

(ii) Hydrogen

bonding and crystal forces usually influence the trace obtained.

(iii) Paraffin

itself gives rise to strong band either at 1460-1380 cm–1 or at

2820-2850 cm–1.

1.6.2. Potassium Bromide Disc

Technique

Procedure : For a window of diameter 1.3

cm, take 100 mg of spectroscopic grade KBr in a previ-ously cleaned agate

pestle and mortar and grind it thoroughly with 0.05-0.5 mg of the sample. Now,

carefully place the sample mixture into the pressing chamber of the mould in

such a manner that it is held between the polished surfaces of the bottom and

top pressing dies. Subsequently, attach the chamber to the vacuum line and

switch-on the vacuum pump ; initially applying a slight negative pressure so as

to compact the powder and then gradually increasing it to ≤ 15 mm Hg for 30 seconds. Finally, enhance the pressing

force to 100,000 lb/in2 or 10-12 tons/in2 for a period of

1-2 minutes. Carefully, release the pressure and dismantle the dies. Now,

remove the window from the mould and keep it in position onto the sample

holder.

Salient Features : The salient features of

KBr-disc technique are stated below :

(i) There

exists a possibility of interaction between vibrations of the sample and the

potassium halide lattice,

(ii) It is

considered to be the most suitable method for other screening of very minute

quantities of substances being eluted from the columns in Gas Liquid

Chromatography (GLC). In actual prac-tice, about 300 mg of the spectroscopic

grade KBr is placed in a short column immediately after the detector.

Consequently, the solid is powdered, pressed into a disc in the normal

procedure and ultimately the absorption spectrum of the trapped substance is

studied,

(iii) It enjoys

the advantage of producing spectra absolutely free from any solvent peaks

(unlike Mull Technique) and hence it is employed extensively in routine

analysis.

Internal Standard for KBr-Disc

Technique : In

quantitative analysis it is essential to examine absolutely uniform discs of identical weights. To achieve this,

known weights of both KBr and analyte are required in the preparation of the

KBr-disc and finally from the absorption data a calibration-curve may be

obtained. In this process, it is a must to weigh the discs and also to measure

their thickness at different points on their surface with the help of a dual

micrometer. In order to overcome this tedious process of measuring disc

thickness carefully the use of an internal standard has been introduced.

Potassium thiocyanate (KSCN) is considered to be the choicest internal standard. In usual

prac-tice, it must be preground, dried and subsequently reground, and used at a

concentration of 0.2% (w/w) along with the dried spectroscopic grade KBr. The

mixture of KBr-KSCN is stored over P2O5.

Procedure : A standard calibration curve

is plotted by thoroughly mixing together about 10% (w/w) of the analyte with the KBr-KSCN mixture and then grinding the

same intimately. Now, the ratio of the thiocyanate absorption at 2125 cm–1

to a selected band absorption of the analyte is plotted against the percent

concentration of the sample. Likewise, an identical disc is prepared with the

unknown sample and the same KBr-KSCN mixture. Finally, its absorbance ratio is

determined and the concentration (of unknown sample) is read off directly from

the standard calibration curve.

1.7. Calibration of Infrared Spectrophotometers

The wavelength (or wave number) scale calibration of

infrared spectrophotometers is usually carried out with the aid of a strip of

polystyrene film fixed on a frame. It consists of several sharp absorption

bands, the wavelengths of which are known accurately and precisely. Basically,

all IR-spectrophotometers need to be calibrated periodically as per the

specific instructions so as to ascertain their accuracy and precision.

Related Topics