Chapter: Power Quality : Harmonics

Harmonics sources from industrial loads

Harmonics sources from industrial

loads:

Modern

industrial facilities are characterized by the widespread application of

nonlinear loads. These loads can make up a significant portion of the total

facility loads and inject harmonic currents into the power system, causing

harmonic distortion in the voltage. This harmonic problem is compounded by the

fact that these nonlinear loads have a relatively low power factor. Industrial

facilities often utilize capacitor banks to improve the power factor to avoid

penalty charges. The application of power factor correction capacitors can

potentially magnify harmonic currents from the nonlinear loads, giving rise to

resonance conditions within the facility. The highest voltage distortion level

usually occurs at the facility’s low-voltage bus where the capacitors are

applied. Resonance conditions cause motor and transformer overheating, and

misoperation of sensitive electronic equipment.

Nonlinear

industrial loads can generally be grouped into three categories: three-phase

power converters, arcing devices, and saturable devices. Sections 4.6.1 to

4.6.3 detail the industrial load characteristics.

1. Three-phase power converters

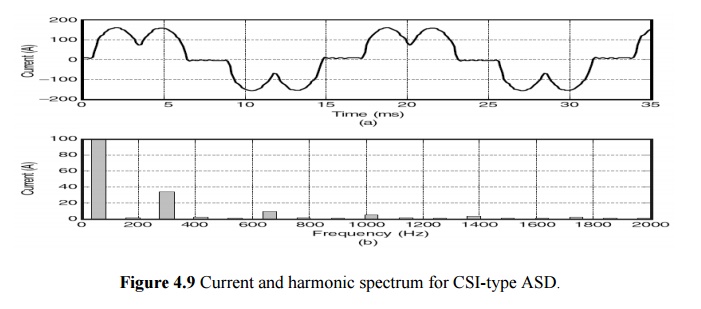

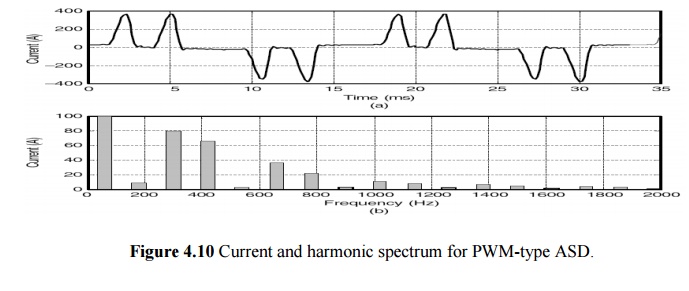

Three-phase electronic power converters differ from single-phase converters mainly because they do not generate third-harmonic currents. This is a great advantage because the third-harmonic current is the largest component of harmonics. However, they can still be significant sources of harmonics at their characteristic frequencies, as shown in Fig. 4.9. This is a typical current source type of adjustable-speed drive. The harmonic spectrum given in Fig. 4.9 would also be typical of a dc motor drive input current. Voltage source inverter drives (such as PWM-type drives) can have much higher distortion levels as shown in Fig. 4.10.

The input

to the PWM drive is generally designed like a three-phase version of the

switch-mode power supply in computers. The rectifier feeds directly from the ac

bus to a large capacitor on the dc bus. With little intentional inductance, the

capacitor is charged in very short pulses, creating the distinctive “rabbit

ear” ac-side current waveform with very high distortion. Whereas the

switch-mode power supplies are generally for very small loads, PWM drives are

now being applied for loads up to 500 horsepower (hp). This is a justifiable

cause for concern from power engineers.

2. DC drives.

Rectification

is the only step required for dc drives. Therefore, they have the advantage of relatively simple control

systems. Compared with ac drive systems, the dc drive offers a wider speed

range and higher starting torque. However, purchase and maintenance costs for

dc motors are high, while the cost of power electronic devices has been

dropping year after year. Thus, economic considerations limit use of the dc

drive to applications that require the speed and torque characteristics of the

dc motor.

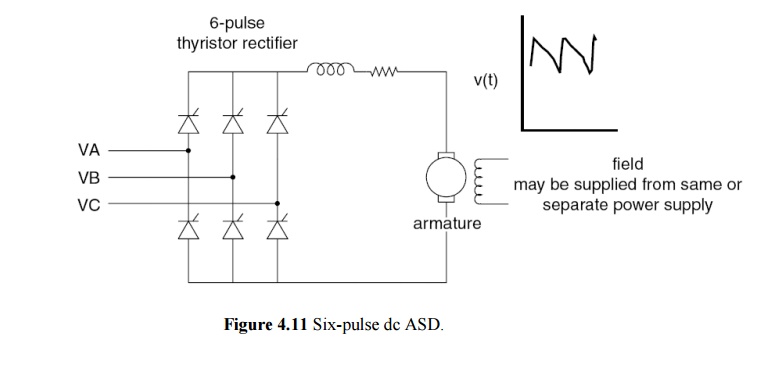

Most dc

drives use the six-pulse rectifier shown in Fig. 4.11. Large drives may employ

a 12-pulse rectifier. This reduces thyristor current duties and reduces some of

the larger ac current harmonics. The two largest harmonic currents for the

six-pulse drive are the fifth and seventh.

They are also the most troublesome in terms of system response. A 12-pulse rectifier in this application can be expected to eliminate about 90 percent of the fifth and seventh harmonics, depending on system imbalances. The disadvantages of the 12-pulse drive are that there is more cost in electronics and another transformer is generally required.

3. AC drives.

In ac

drives, the rectifier output is inverted to produce a variable-frequency ac voltage for the motor. Inverters are

classified as voltage source inverters (VSIs) or current source inverters (CSIs).

A VSI requires a constant dc (i.e., low-ripple) voltage input to the inverter

stage. This is achieved with a capacitor or LC

filter in the dc link. The CSI requires a constant current input; hence, a

series inductor is placed in the dc link.

AC drives

generally use standard squirrel cage induction motors. These motors are rugged,

relatively low in cost, and require little maintenance. Synchronous motors are

used where precise speed control is critical.

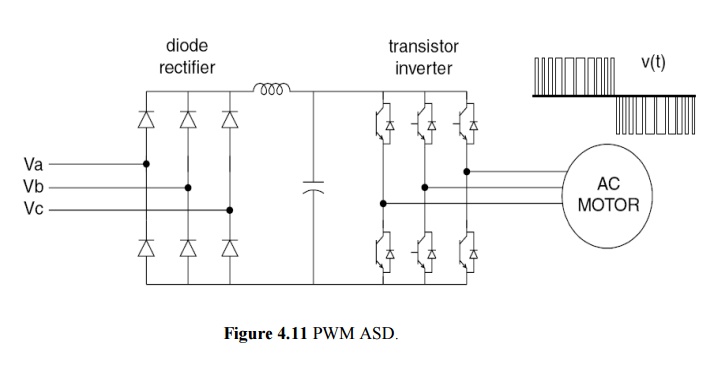

A popular

ac drive configuration uses a VSI employing PWM techniques to synthesize an ac

waveform as a train of variable-width dc pulses (see Fig. 4.11). The inverter

uses either SCRs, gate turnoff (GTO) thyristors, or power transistors for this

purpose. Currently, the VSI PWM drive offers the best energy efficiency for

applications over a wide speed range for drives up through at least 500 hp.

Another advantage of PWM drives is that, unlike other types of drives, it is

not necessary to vary rectifier output voltage to control motor speed. This

allows the rectifier thyristors to be replaced with diodes, and the thyristor

control circuitry to be eliminated.

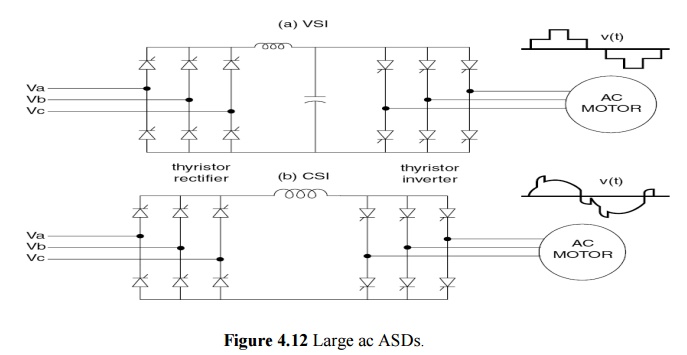

Very high

power drives employ SCRs and inverters. These may be 6- pulse, as shown in Fig.

4.12, or like large dc drives, 12-pulse. VSI drives (Fig. 4.12a) are limited to applications that do

not require rapid changes in speed. CSI drives (Fig. 4.12b) have good acceleration/deceleration characteristics but require

a motor with a leading power factor (synchronous or induction with capacitors)

or added control circuitry to commutate the inverter thyristors. In either

case, the CSI drive must be designed for use with a specific motor. Thyristors

in current source inverters must be protected against inductive voltage spikes,

which increases the cost of this type of drive.

4. Impact of operating condition.

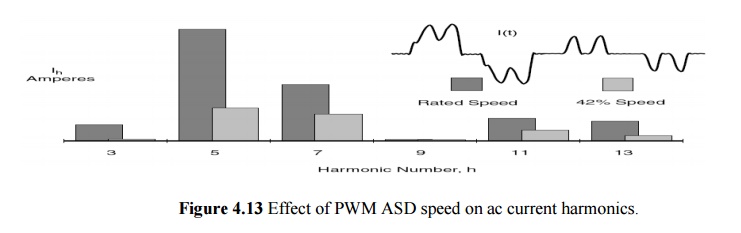

The

harmonic current distortion in adjustable-speed drives is not constant. The waveform changes significantly for different

speed and torque values. Figure 4.13 shows two operating conditions for a PWM

adjustablespeed drive. While the waveform at 42 percent speed is much more

distorted proportionately, the drive injects considerably higher magnitude

harmonic currents at rated speed. The bar chart shows the amount of current

injected. This will be the limiting design factor, not the highest THD.

Engineers should be careful to understand the basis of data and measurements

concerning these drives before making design decisions

5. Arcing devices

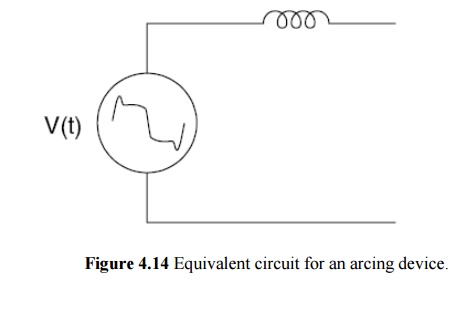

This

category includes arc furnaces, arc welders, and discharge-type lighting

(fluorescent, sodium vapor, mercury vapor) with magnetic

(rather

than electronic) ballasts. As shown in Fig. 4.14, the arc is basically a

voltage clamp in series with a reactance that limits current to a reasonable

value.

The

voltage-current characteristics of electric arcs are nonlinear. Following arc

ignition, the voltage decreases as the arc current increases, limited only by

the impedance of the power system. This gives the arc the appearance of having

a negative resistance for a portion of its operating cycle such as in

fluorescent lighting applications.

In

electric arc furnace applications, the limiting impedance is primarily the

furnace cable and leads with some contribution from the power system and

furnace transformer. Currents in excess of 60,000 A are common.

The

electric arc itself is actually best represented as a source of voltage

harmonics. If a probe were to be placed directly across the arc, one would

observe a somewhat trapezoidal waveform. Its magnitude is largely a function of

the length of the arc. However, the impedance of ballasts or furnace leads acts

as a buffer so that the supply voltage is only moderately distorted. The arcing

load thus appears to be a relatively stable harmonic current source, which is

adequate for most analyses. The exception occurs when the system is near

resonance and a Thevenin equivalent model using the arc voltage waveform gives

more realistic answers.

6. Saturable devices

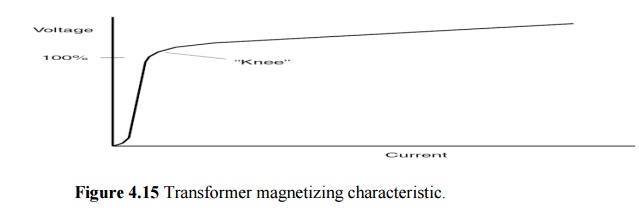

Equipment

in this category includes transformers and other electromagnetic devices with a

steel core, including motors. Harmonics are generated due to the nonlinear

magnetizing characteristics of the steel (see Fig. 4.15).

Power

transformers are designed to normally operate just below the “knee” point of

the magnetizing saturation characteristic. The operating flux density of a

transformer is selected based on a complicated optimization of steel cost,

no-load losses, noise, and numerous other factors. Many electric utilities will

penalize transformer vendors by various amounts for no-load and load losses,

and the vendor will try to meet the specification with a transformer that has

the lowest evaluated cost. A high-cost penalty on the no-load losses or noise

will generally result in more steel in the core and a higher saturation curve

that yields lower harmonic currents.

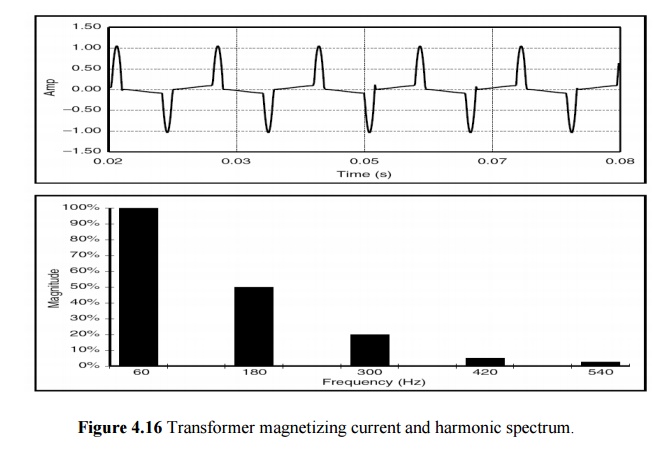

Although

transformer exciting current is rich in harmonics at normal operating voltage

(see Fig. 4.16), it is typically less than 1 percent of rated full load

current. Transformers are not as much of a concern as electronic power

converters and arcing devices which can produce harmonic currents of 20 percent

of their rating, or higher. However, their effect will be noticeable,

particularly on utility distribution systems, which have hundreds of

transformers. It is common to notice a significant increase in triplen harmonic

currents during the early morning hours when the load is low and the voltage

rises. Transformer exciting current is more visible then because there is

insufficient load to obscure it and the increased voltage causes more current

to be produced. Harmonic voltage distortion from transformer over excitation is

generally only apparent under these light load conditions.

Some

transformers are purposefully operated in the saturated region. One example is

a triplen transformer used to generate 180 Hz for induction furnaces.

Motors

also exhibit some distortion in the current when overexcited, although it is

generally of little consequence. There are, however, some fractional

horsepower, single-phase motors that have a nearly triangular waveform with

significant third-harmonic currents.

Related Topics