Chapter: Mechanical : Advanced IC Engines : Engine Exhaust Emission Control

HC emission and Smoke

HC emission:

Hydrocarbons

(HC) are the consequence of incomplete combustion of hydrocarbon fuel. The

level of unburned hydrocarbons (HC) in the exhaust gases specified in terms of

total hydrocarbon concentration expressed in parts per million carbon atoms.

Engine exhaust gases contain a wide variety of hydrocarbon compounds.

HC is

basically divided into two classes namely methane and non-methane hydrocarbons.

Below table shows classifications of hydrocarbons according to their relative

reactivity which is the scale of 0 to 100based on their NO2

formation relatively to HC.

Smoke

Formations of smoke and affecting factors:

Engine

Exhaust smoke is the result of incomplete combustion. Smoke from exhaust is a

visible indicator of the combustion process within the engine. It is generated

at any volume in the engine where mixture is rich. The fuel air ratio greater

than 1.5 and pressures developed in diesel engine produced soot. Once soot is

formed, it can burn if it finds sufficient O2 otherwise it comes out

with exhaust. It becomes visible if it is dense. The size of the soot particles

effect the appearance of smoke. The soot particles agglomerate into bigger

particles which have an objectionable darkening effect on diesel exhaust.

Measurement of smoke:

The main

purpose of smoke measurement is to quantify the black smoke from diesel engine.

As visibility is the main criterion in evaluating the intensity of smoke,

development or principle of the smoke meter depends on the light obstruction by

the smoke.

Even

though there are several smoke measuring types, two basic and main types are

discussed in this lecture.

1. Hartridge

smoke meter.

2. Bosch

smoke meter.

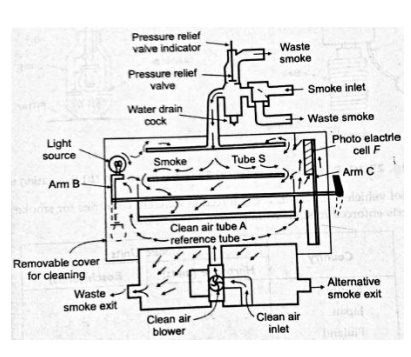

Hartridge smoke meter:

The

arrangement is shown in the figure. This consists of two optically identical

tubes, one containing clean air and other the moving sample of the smoke. The

clean air tube is taken as reference. A light source and photo-electric cell

mounted facing each other on swinging arms. Movement of the change-over knob

alters their position from 0-100, indicating the light absorbed by the smoke in

hartridge units. A small fan blows air into the clean air-tube. The air flow

the open ends of the tube across the surfaces of the light source and the

photo-electric cell, to provide cooling and to protect them against sooting by

the smoke.

The

sampling probe is connected either to a tapping on the exhaust pipe. The smoke

meter is switched on and control lever set to bring the clean air tube between

light and cell. The smoke meter dial should read zero otherwise the meter is to

adjusted to read zero. The control lever valve, the meter gives continuous and

direct reading of the smoke density.

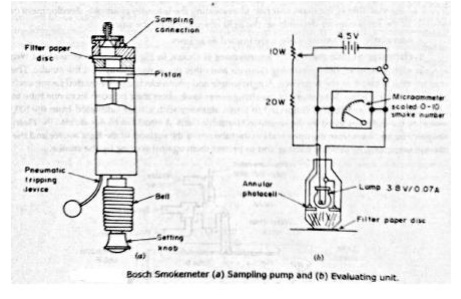

Bosch smoke meter:

The bosch

meter is widely accepted for measuring the diesel engine smoke. This concists

of sampling pump and evaluating unit shown in the figure given below. The

sampling pump is used to draw nearly 300CC of exhaust gas by means of spring

operated pump and released by pneumatic operation of a diaphragm. The gas

sample is drawn is through the filter paper darkening to give precise

assessment of the intensity of the spot. The intensity of the spot is measured

on a scale of 10 arbitary units called arbitrary units, called Bosch smoke units

for white to black.

Related Topics