Chapter: Aquaculture Principles and Practices: Grey Mullets and Milkfish

Fry collection and induced spawning of Milkfish

Fry collection and induced spawning

As in the case of major grey mullet species, the milkfish do not mature and spawn naturally in confined waters. They seem to spawn in the sea near the coast and the small larvae (12–15mm in length) occur periodically along the sandy coasts and in the estuaries. The collection and rearing of fry from these areas for sale to farmers has become an industry of importance, employing a large number of people in Indonesia, the Philippines and Taiwan.

There seem to be some differences in the periods of availability of larvae and fry along the coasts of these countries. In the Philippines and Taiwan, the season for collection extends from March or April to August, but the peak season in the Philippines is May/June and in Taiwan it is April/May. In Indonesia there are two seasons, one from March to May and the second from September to December.The peak period for collection is October/November.

Fry collection methods

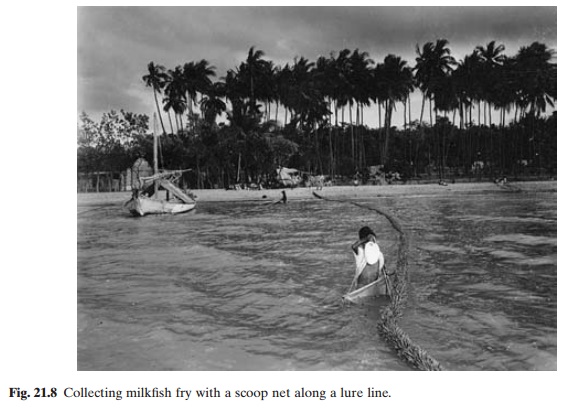

The most common collecting equipment comprises different types of dip nets, such as the triangular scissor net in the Philippines and the scoop net in Taiwan. Dip nets are particularly suited for areas with large concentrations of fry. Seines, drag nets and traps are also used by some fishermen. In traditional methods of fry capture in Indonesia special fry-congregating devices are used, such as rock walls or lure lines made of fibre ropes strung with plaited strips of coconut and banana leaves (fig. 21.8). In areas where the concentration of fry is low, such lure lines may be deployed in a circle with one end tied to a post. When fry are observed under the lure, the fishermen reduce the circle by pulling the free end of the line and dip out the fry with small dip nets made of coarse cloth. The best collections are made at creek mouths, the leeward side of sandbars in estuarine areas, etc., at high tides during full and new moon periods.

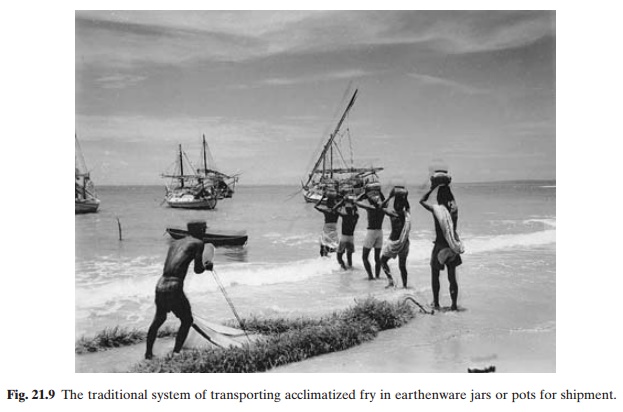

The fry captured are between 10 and 30mm in length and need to be handled carefully. In Indonesia and the Philippines they are transferred to earthenware jars and acclimatized to lower salinity conditions by gradually diluting the water with fresh water. In Taiwan, the fry are stored temporarily in wooden buckets or cement troughs in sea water. They are packed in plastic bags containing water of lower salinity (10–15ppt) and filled with oxygen for transport. In the Philippines, fry used to be transported in earthenware jars of 15–30l capacity, each containing 1500–3500 fry sorted according to size (fig. 21.9). Now, plastic bags filled with oxygen are commonly used in the Philippines as well. Flat bamboo baskets coated with cement or tar are the traditional containers for fry transport in Indonesia. Each basket carries about 20000–40000 fry in dilute sea water, with daily changes of water. During long-distance transport or storage, the fry are fed on slightly roasted rice flour or wheat flour twice a day, and occasionally on mashed hard-boiled eggs.

Induced spawning

Attempts have been made to develop a hatchery technology for the production of milkfish fry, in order to meet the increasing demands created by intensified farming techniques. The sexes can be distinguished by external characteristics. Females are distinguishable by the presence of three visible pores in the urogenital region, whereas the males show only two pores externally (Chaudhuri et al., 1976).

Mature females collected from the sea with ova of about 0.7–0.8mm diameter can be induced to spawn by the administration of carp pituitary homogenate and semi-purified salmon gonadotropin (SG-G 100) in combination with HCG (Vanstone et al., 1977; Chaudhuri et al., 1978; Kuo et al., 1979; Liao et al., 1979). The average number of eggs spawned annually is estimated to be 2 million/kg body weight. The eggs can be fertilized with milt from untreated males. Where necessary, the free flow of milt is induced by the injection of androgen or salmon pituitary preparations.

Even though the fertilized eggs, which have a diameter of 1.1–1.25mm, can be hatched in salt water (30–34ppt) containers in 25–28.5 hours at temperatures of 26.4–29.9°C, it has been difficult to rear the post-larvae to the fry stage in any significant numbers. Survival rates under experimental conditions of 9–47 per cent have been reported during a 21-day rearing period (Liao et al., 1979). Fed initially on fertilized oyster eggs for 14 days and thereafter on a combination of copepods, Artemia nauplii, flour and prepared feed, the fry could be grown to a mean size of 14.5mm in 20 days.

A system of propagation that appears to hold great possibilities is spawning in open waters. It has been shown that milkfish can attain sexual maturity and spawn in cages installed in protected bays. Floating cages filled with fine-meshed hapa nets to retain spawned milkfish eggs have been successfully used by research institutions for large-scale spawning. The eggs are collected from the cages with a specially designed conical egg-sweeping net, with a rigid frame. This device is reported to have been very successful in the recovery of fertilized eggs and thereby in the production of hatchery-produced fry.

Rearing of fry

Considerable attention is paid to fry rearing in the Philippines. Although fry can be introduced into rearing ponds after a brief period of acclimatization in small nursery pools, as done elsewhere, many Philippine farms maintain separate nursery and transition ponds for fry rearing. They normally represent about 3–5 per cent of the farm area. The typically shallow nursery ponds ranging in size from 1000 to 4000m2 are located close to transition ponds which are meant for stunting the fry for later (off-season) stocking. They usually average about 1ha in area. The nursery ponds are provided with catching ponds, sluice gates and a canal system for easy water distribution and transfer of stock. When the nurseries form a unit of the production farm, their preferred location is in the centre of the farm to facilitate transfer to fingerlings. Milk-fish fry are usually grown to fingerling size in ponds with rich growths of the benthic biological complex predominated by blue-green algae (Myxophyceae), generally referred to as lablab. It includes large populations of bacteria, diatoms, green algae (Chlorophyceae) and animal components like protozoans, flat worms, larvae and adults of molluscs, polychaete worms, copepods and larval forms of decapods and insects. In recent years, many farmers have adopted the practice of raising mainly planktonic organisms as food for milkfish fry. In shallow ponds, the distinction between benthic growths and plankton is seldom precise. When plankton is the main source of food, the ponds are generally made deeper for better growth of phyto- and zooplanktonic organisms.

Methods of increasing planktonic growth by fertilization and water management are fairly standard and have been described. The production and maintenance of the benthic algal complex involves considerable skill and attention. The preparation of the ponds starts about two months before the fry are introduced. The ponds are drained completely during low tides. The bottom is levelled, raked with a wooden rake or ploughed to bring the sub-surface soil nutrients to the surface and to eradicate weeds. The pond bottom is levelled in such a way that it slopes gradually towards the deepest portion of the pond at the sluice gate. Often a shallow diagonal canal is made from the gate to the opposite corner to serve as a refuge for fry and fingerlings during hot days, and to facilitate transfer or harvesting of the stock. The pond is then dried and exposed to the sun for two or three days until the layer of surface soil cracks, after which some water is let in. In order to get rid of any predatory fish or other pests burrowing in the mud, this process of drying and draining may be repeated a few times. Besides eradicating pests and predators, drying also helps in the mineralization of organic matter in the soil. The water gates of the pond are protected with fine-meshed screens to prevent the entry of fish or other organisms from outside.

The ponds are then treated with chicken manure at the rate of 2 tons/ha. Water is let in just to cover the pond bottom and 150kg/ha of 16–20–0 NPK fertilizer, or half that quantity of 18–46–0 NPK fertilizer per ha, are added after two or three days. In order to speed up the breakdown of chicken manure, urea may be added at the rate of 25kg/ha. Within a week lablab growth starts.The water level in the pond is then gradually increased to 25–30cm in a period of one to one and a half months, increasing the level by 3–5cm each time. Sudden increases in water level can result in the detachment of lablab from the bottom.

The maintenance of this benthic complex requires proper water management and grazing levels. If overgrowth of the complex occurs, it has to be controlled by additional stocking of fry. Detached lablab is not allowed to accumulate and disintegrate in the ponds, and is removed and dried for later use as feed for milkfish. Organisms that feed on or disturb the growth of lablab are detected and eradicated as far as possible to maintain the algal pasture at an optimum abundance. Further applications of NPK fertilizers are made, if necessary, at intervals of one to two weeks to maintain the growth of lablab.

Lowering the salinity in the ponds by admixture with fresh water induces growths of filamentous algae which are known in the Philippines as ‘lumut’. This is avoided, not only because the fry are not able to feed on them, but also because they become entangled in the filaments.

If the fry are to be reared on plankton, the pond water is maintained at a depth of 75– 100cm, and chemical fertilizers are applied at the same rate as for lablab growth. The fertilizer is placed on a platform from which it can dissipate into the pond. In a few days a plankton bloom develops and the visibility under water is about 15–40cm. In case of poor growth, a further application of fertilizer is made. If there is an excessive growth of plankton, fertilization is not suspended but a part of the pond water is replaced.

Fry can be stocked directly in the nursery ponds if the salinity of the water in which they are transported is approximately the same as the salinity of the pond water. If there is a difference of over 5ppt, it is considered preferable to acclimatize them before transfer.

The density of fry in the nurseries is generally 30–50 per m2. Nursery management involves the maintenance of suitable conditions for the growth of fry and its natural food (lablab). In order to avoid salinity increases during the summer months, some exchange of water may be needed. It is reported that the growth of milkfish fry is retarded at salinities above 45ppt. Favourable temperatures for growth are above 23°C. If the growth of natural food is not adequate for the stock, artificial feeds like rice bran or dried lumut are provided. In about one and a half to two months, the fry have grown to a weight of 1–3g and are then either stocked in the rearing ponds or transferred to transition or stunting ponds.

The transition or stunting pond, as the name implies, is meant to hold the fingerlings in a stunted condition for stocking later, during the off-season for fry. The stocking density in the transition ponds is about 10–15 fingerlings/m2, and they subsist on lablab or plankton for one to two months. Fertilization may be carried out to increase natural food production, but this may not be enough to keep the fish in a healthy but stunted condition. Supplementary daily feeding with rice bran at the rate of 5 per cent of the body weight may be required,if the fingerlings have to be held for prolonged periods (up to six months or more), or if they become too thin.

In Taiwan, where overwintering of fry is required, the fry are kept in shallow (20–40cm deep) ponds with 1.5m deep wintering ditches protected on the windward side by windbreaks of thatched bamboo frames. For producing stunted fingerlings, fry are stocked at the rate of 300000–500000 per ha and fed on benthic algae and rice bran, peanut meal or soybean meal. These wintering ponds may also be used for overwintering undersized fish from the previous harvest.

Related Topics