Chapter: Mechanical : Dynamics of Machines : Force Analysis

Flywheel

FLYWHEEL

A flywheel used in machines serves as a reservoir, which stores energy

during the period when the supply of energy is more than the requirement, and

releases it during the period when the requirement of energy is more than the

supply.

In case of steam engines, internal combustion engines, reciprocating

compressors and pumps, the energy is developed during one stroke and the engine

is to run for the whole cycle on the energy produced during this one stroke.

For example, in internal combustion engines, the energy is developed only

during expansion or power stroke which is much more than the engine load and no

energy is being developed during suction, compression and exhaust strokes in

case of four stroke engines and during compression in case of two stroke engines.

The excess energy developed during power stroke is absorbed by the flywheel and

releases it to the crankshaft during other strokes in which no energy is

developed, thus rotating the crankshaft at a uniform speed. A little

consideration will show that when the flywheel absorbs energy, its speed

increases and when it releases energy, the speed decreases. Hence a flywheel

does not maintain a constant speed, it simply reduces the fluctuation of speed.

In other words, a flywheel controls the speed variations caused by the

fluctuation of the engine turning moment during each cycle of operation.

In

machines where the operation is intermittent like *punching machines, shearing

machines, rivetting machines, crushers, etc., the flywheel stores energy from

the power source during the greater portion of the operating cycle and gives it

up during a small period of the cycle. Thus, the energy from the power source

to the machines is supplied practically at a constant rate throughout the

operation.

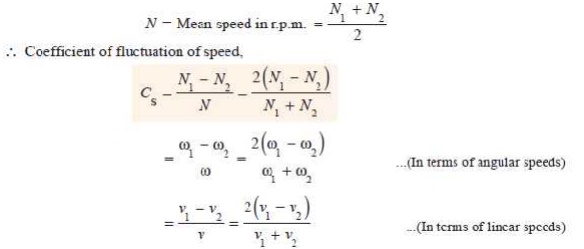

COEFFICIENT OF FLUCTUATION OF SPEED

The difference between the maximum and minimum speeds during a cycle is

called the maximum fluctuation of speed . The ratio of the maximum

fluctuation of speed to the mean speed is called the coefficient

of fluctuation of speed.

Let N1 and N2 = Maximum and minimum speeds in r.p.m.

during the cycle, and

The coefficient of fluctuation of speed is a limiting factor in the

design of flywheel. It varies depending upon the nature of service to which the

flywheel is employed.

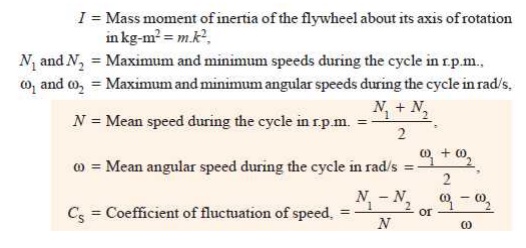

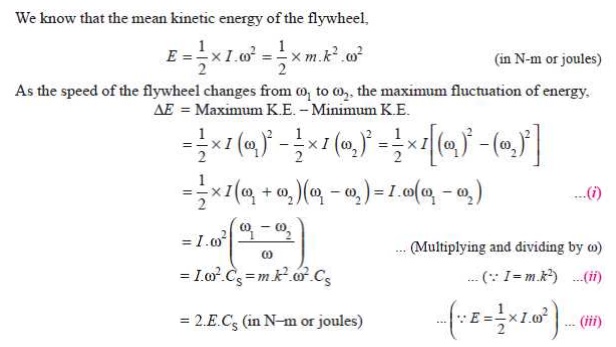

ENERGY STORED IN A FLYWHEEL

A flywheel is shown in Fig. 16.5. We have discussed in Art. 16.5 that

when a flywheel absorbs energy, its speed increases and when it gives up

energy, its speed decreases.

Let

m = Mass of the flywheel

in kg,

k = Radius of gyration of the flywheel

in metres,

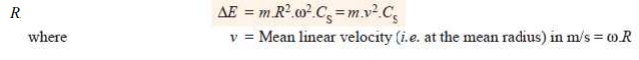

The radius

of gyration (k) may be taken equal to

the mean radius of the rim (R),

because the thickness of rim is very small as compared to the diameter of rim.

Therefore, substituting k = R, in equation (ii), we have

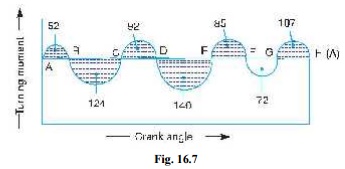

Q. The

turning moment diagram for a multicylinder engine has been drawn to a scale 1

m m = 600 N -m vertically and 1 m m = 3┬░ horizontally. The intercepted areas between the output torque curve and the mean

resistance line, taken in order from

one end, are as follows :

+ 52, ŌĆō 124, + 92, ŌĆō 140, + 85, ŌĆō 72 and + 107 m m2, when the engine is running at a speed of 600 r.p.m. If the total fluctuation of speed is not to exceed (-+) 1.5% of the mean, find the necessary mass of the flywheel of radius 0.5 m.

Solution. Given : N = 600 r.p.m. or Žē = 2 ŽĆ ├Ś 600 / 60 = 62.84 rad / s ; R

= 0.5 m

Since the

total fluctuation of speed is not to exceed (-+) 1.5% of the mean

speed, therefore Žē 1 ŌĆō Žē 2 = 3% Žē = 0.03 Žē

Let the

total energy at A = E, then referring to Fig. 16.7,

Energy at

B = E + 52 ...(Maximum

energy)

Energy at

C = E + 52 ŌĆō 124 = E ŌĆō 72

Energy at

D = E ŌĆō 72 + 92 = E + 20

Energy at

E = E + 20 ŌĆō 140 = E ŌĆō 120 ...(Minimum energy)

Energy at

F = E ŌĆō 120 + 85 = E ŌĆō 35

Energy at

G = E ŌĆō 35 ŌĆō 72 = E ŌĆō 107

Energy at

H = E ŌĆō 107 + 107 = E = Energy at A

We know

that maximum fluctuation of energy,

ŌłåE = Maximum energy ŌĆō Minimum energy

= (E + 52) ŌĆō (E ŌĆō 120) = 172 = 172 ├Ś 31.42

= 5404 N-m

Let m =

Mass of the flywheel in kg. We know that maximum fluctuation of energy (Ōłå E ),

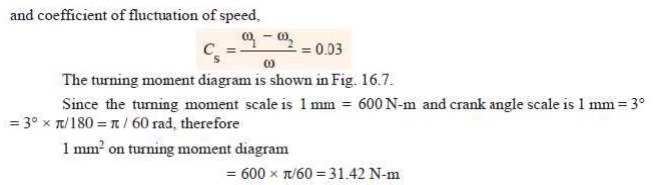

Q. A shaft fitted with a flywheel rotates at 250

r.p.m. and drives a machine. The

torque of machine varies in a cyclic manner over a period of 3 revolutions. The torque rises from 750 N-m to 3000 N-m uniformly during 1/2 revolution and remains constant for the

following revolution. It then falls

uniformly to 750 N-m during the next

1/2 revolution and remains constant for one revolution, the cycle being repeated thereafter.

Determine the power required to drive the

machine and percentage fluctuation in speed, if the driving torque applied to

the shaft is constant and the mass of the flywheel is 500 kg with radius of

gyration of 600 m m.

Solution. Given : N = 250 r.p.m. or Žē = 2ŽĆ ├Ś 250/60 = 26.2 rad/s ; m = 500 kg ; k

= 600 mm = 0.6 m

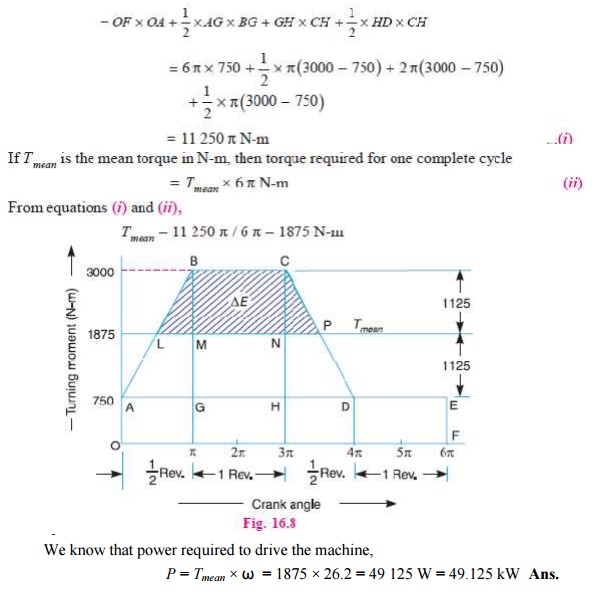

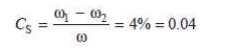

The turning moment diagram for the complete

cycle is shown in Fig. 16.8. We know that the torque required for one complete

cycle

= Area of figure OABCDEF

=Area OAEF + Area ABG + Area BCHG + Area CDH

Power

required to drive the machine

We know that power required to drive the

machine,

P = Tmean ├Ś Žē = 1875 ├Ś 26.2 = 49 125 W = 49.125 kW

Ans.

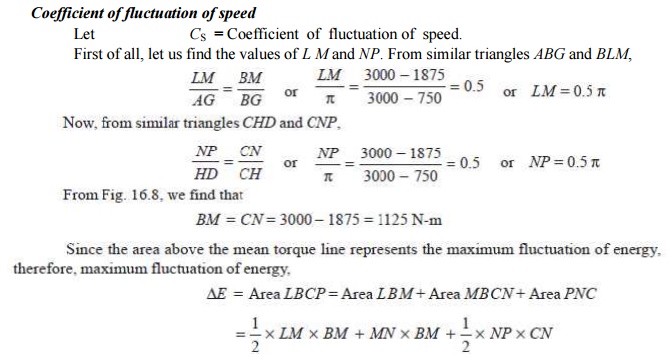

Coefficient

of fluctuation of speed

Let CS = Coefficient of fluctuation of speed.

First of

all, let us find the values of L M

and NP. From similar triangles ABG and BLM,

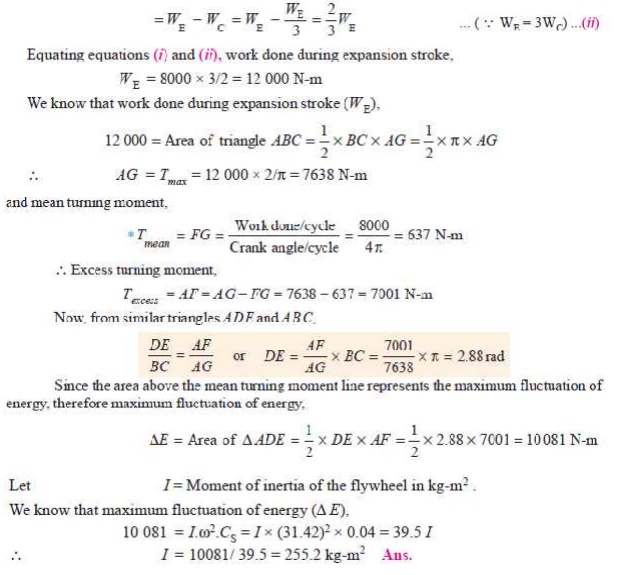

Solution. Given : P = 20 kW = 20 ├Ś 10 3 W; N = 300 r.p.m. or Žē = 2ŽĆ ├Ś 300/60 = 31.42 rad/s

Since the total fluctuation of speed (Žē 1 ŌĆō Žē 2) is not to exceed ┬▒ 2 per cent of the mean speed ), therefore

Žē 1 ŌĆō Žē 2 = 4% Žē

and

coefficient of fluctuation of speed,

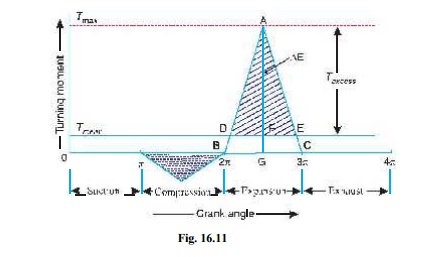

The

turning moment-crank angle diagram for a four stroke engine is shown in Fig.

16.11. It is assumed to be triangular during compression and expansion strokes,

neglecting the suction and exhaust strokes.

We know

that for a four stroke engine, number of working strokes per cycle,

n = N/2 =

300 / 2 = 150

Ōł┤ Work

done/cycle =P ├Ś 60/ n = 20 ├Ś 10 3 ├Ś 60/150 = 8000 N-m ------------(i)

Since the

work done during suction and exhaust strokes is negligible, therefore net work

done per cycle (during compression and expansion strokes)

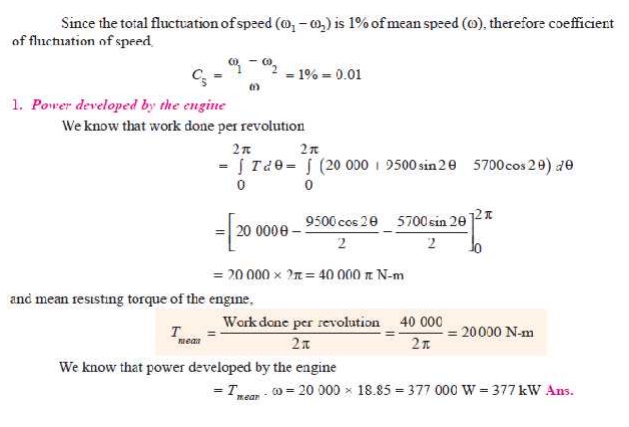

Q. The turning moment curve for an engine is

represented by the equation, T = (20 000 + 9500 sin 2╬Ė ŌĆō 5700 cos 2╬Ė ) N-m, where ╬Ė is the angle moved by the crank from inner dead

centre. If the resisting torque is constant, find:

1. Power developed by the engine ; 2. Moment of inertia of flywheel in

kg-m2, if the total fluctuation

of speed is not exceed 1% of mean speed which is 180 r.p.m; and 3. Angular acceleration of the flywheel

when the crank has turned through 45┬░ from inner dead centre.

Solution.

Given : T

= (20 000 + 9500 sin 2╬Ė ŌĆō 5700 cos 2╬Ė ) N-m ; N = 180 r.p.m. or

Žē = 2ŽĆ ├Ś 180/60

= 18.85 rad/s

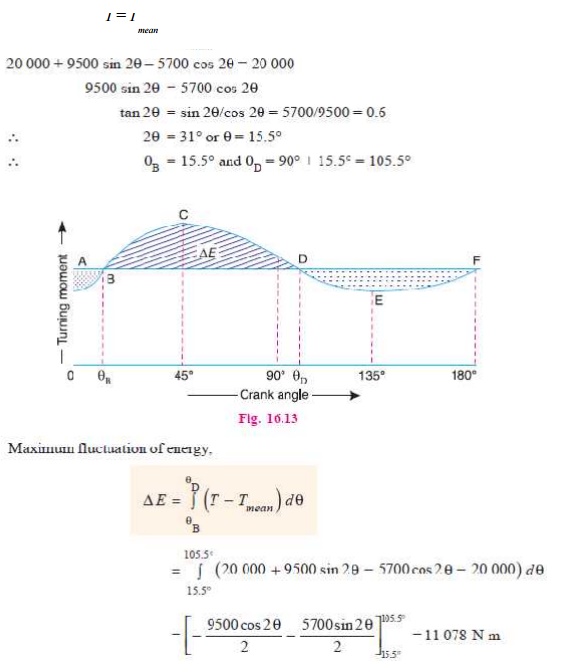

2. Moment

of inertia of the flywheel

Let I = Moment of inertia of the flywheel in kg-m2.

The

turning moment diagram for one stroke (i.e.

half revolution of the crankshaft) is shown in Fig. 16.13. Since at points B and D, the torque exerted on the crankshaft is equal to the mean

resisting torque on the flywheel, therefore,

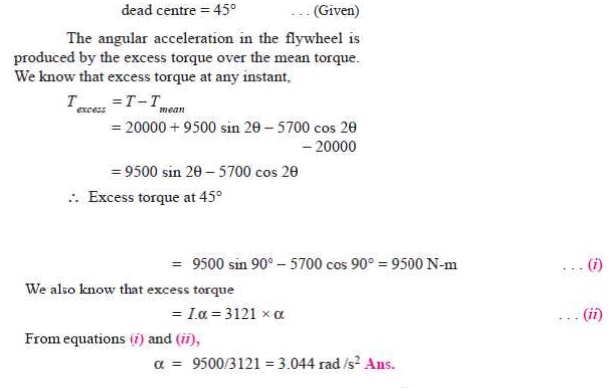

3. Angular acceleration of the flywheel

Let ╬▒ = Angular acceleration of the flywheel, and ╬Ė = Angle turned by the crank from inner

DIMENSIONS OF THE FLYWHEEL RIM

Consider a

rim of the flywheel as shown in Fig. 16.17.

Let D = Mean diameter of rim in metres,

R = Mean

radius of rim in metres,

A =

Cross-sectional area of rim in m2,

Žü =

Density of rim material in kg/m3,

N = Speed

of the flywheel in r.p.m.,

Žē = Angular velocity of the flywheel in rad/s,

v = Linear velocity at the mean

radius in m/s

Žā = Tensile stress or hoop stress in N/m2 due to the

centrifugal force.

Consider a small element of the rim as shown shaded in Fig. 16.17. Let

it subtends an angle ╬┤╬Ė at the centre of the flywheel.

Volume of the small element

= A ├Ś R.╬┤╬Ė Ōł┤ Mass of the small element

dm = Density ├Ś volume = Žü .A .R.╬┤╬Ė

and

centrifugal force on the element, acting radially outwards, dF =

dm.Žē 2.R = Žü .A .R2.Žē 2.╬┤╬Ė

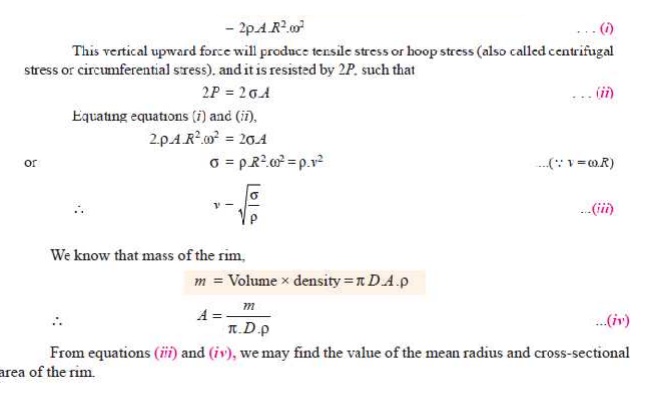

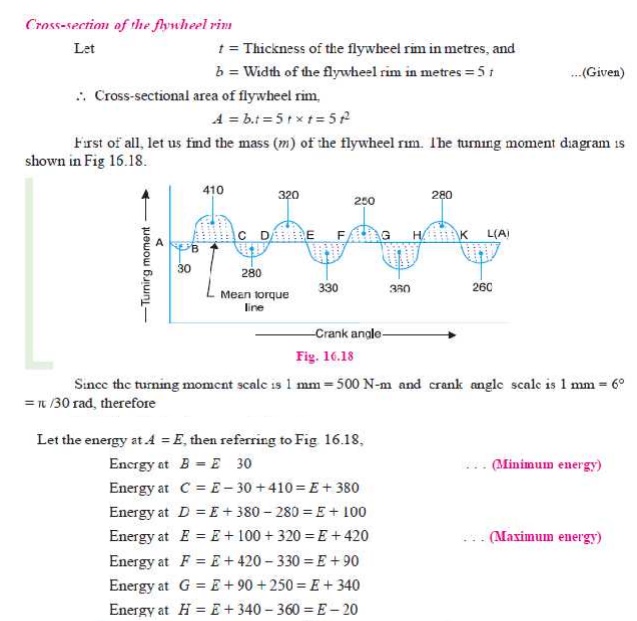

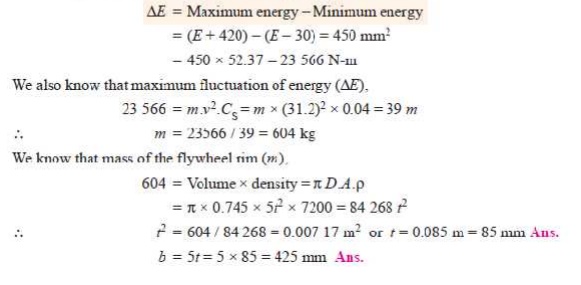

Q.The turning moment diagram for a multi-cylinder

engine has been drawn to a scale of 1 mm to 500 N-m torque and 1 mm to 6┬░

of crank displacement. The intercepted areas between output torque curve and

mean resistance line taken in order from one end, in sq. mm are ŌĆō 30, + 410, ŌĆō

280, + 320, ŌĆō 330, + 250, ŌĆō 360, + 280, ŌĆō 260 sq. mm, when the engine is

running at 800 r.p.m.The engine has a stroke of 300 mm and the fluctuation of

speed is not to exceed ┬▒ 2% of the mean speed. Determine a suitable diameter

and cross-section of the flywheel rim for a limiting value of the safe

centrifugal stress of 7 MPa. The material density may be assumed as 7200 kg/m3.

The width of the rim is to be 5 times the thickness.

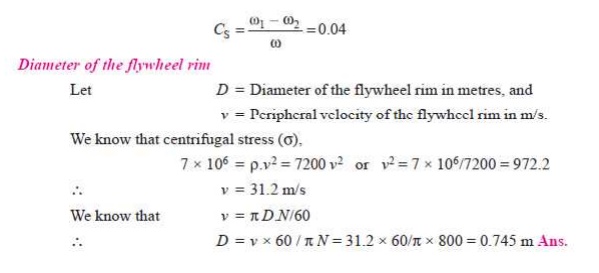

Solution. Given : N = 800 r.p.m. or Žē = 2ŽĆ ├Ś 800 / 60 = 83.8 rad/s; *Stroke = 300 mm ; Žā = 7 MPa =

7 ├Ś 10 6 N/m2 ; Žü = 7200

kg/m3

Since the fluctuation of speed is ┬▒ 2% of mean speed, therefore total fluctuation of speed,

Žē 1 ŌĆō Žē 2 = 4% Žē = 0.04 Žē

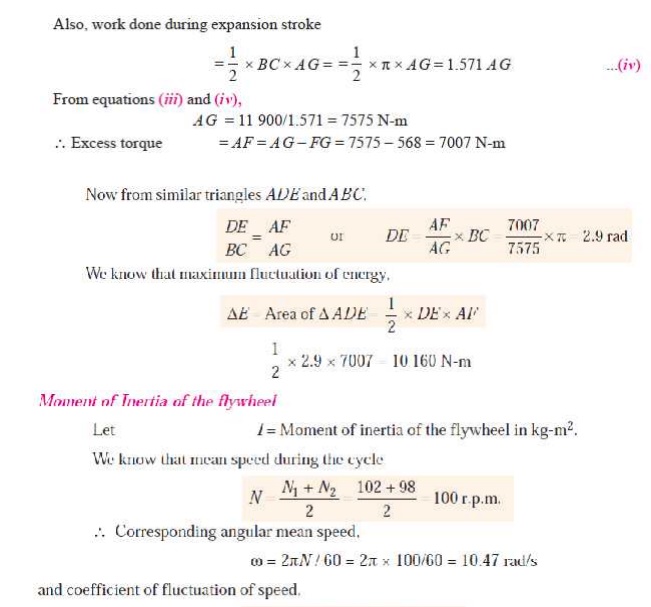

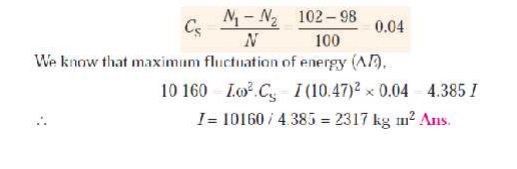

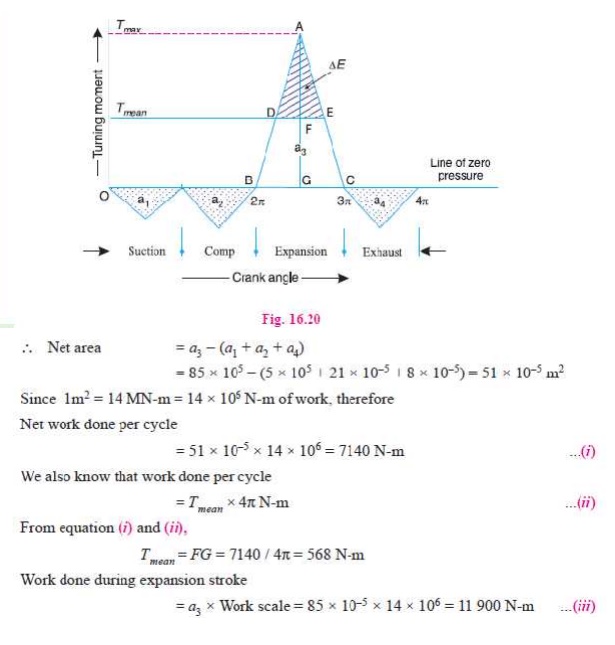

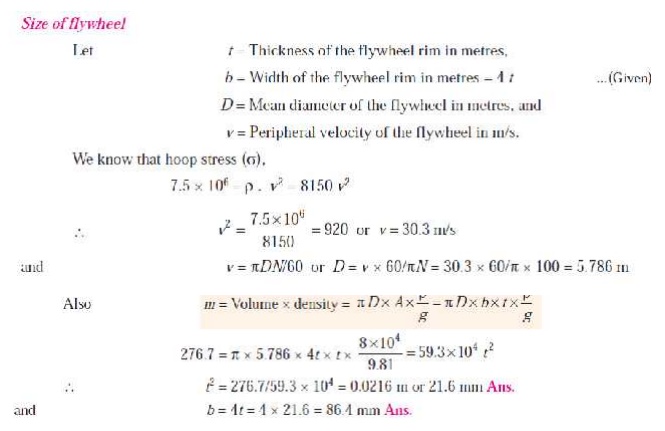

Q. The turning moment diagram of a four stroke engine may be assumed for the sake of simplicity to be represented by four triangles in each stroke. The areas of these triangles are as follows: Suction stroke = 5 ├Ś 10 ŌĆō5 m2; Compression stroke = 21 ├Ś 10 ŌĆō5 m2; Expansion stroke = 85 ├Ś 10 ŌĆō5 m2; Exhaust stroke = 8 ├Ś 10 ŌĆō5 m2.

All the areas excepting expression stroke are negative. Each m2 of area represents 14 MN-m of work.

Assuming the resisting torque to be constant, determine

the moment of inertia of the flywheel to keep the speed between 98 r.p.m. and

102 r.p.m. Also find the size of a rim-type flywheel based on the minimum

material criterion, given that density of flywheel material is 8150 kg/m3

; the allowable tensile stress of the flywheel material is 7.5 MPa. The rim

cross-section is rectangular, one side being four times the length of the

other.

Solution. Given: a1 = 5 ├Ś 10 ŌĆō5 m2; a2

= 21 ├Ś 10 ŌĆō5 m2; a3 = 85 ├Ś 10 ŌĆō5 m2; a4 = 8 ├Ś 10 ŌĆō5 m2; N2 = 98 r.p.m.; N1 = 102 r.p.m.; Žü = 8150 kg/m3; Žā = 7.5 MPa

= 7.5 ├Ś 10 6 N/m2

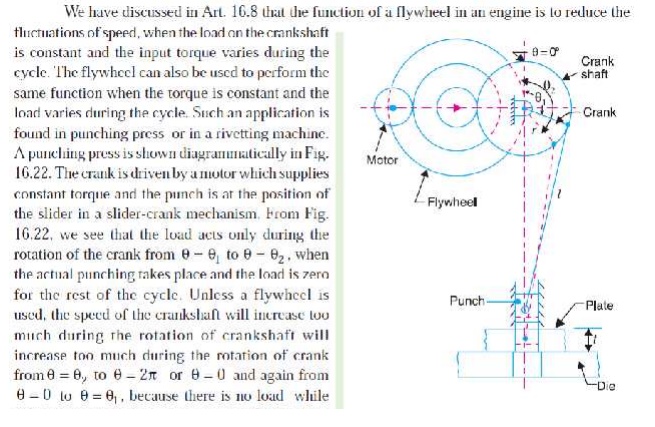

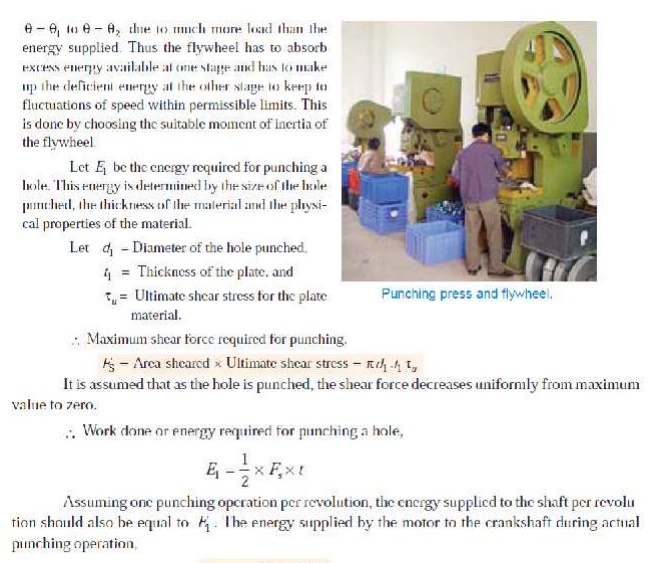

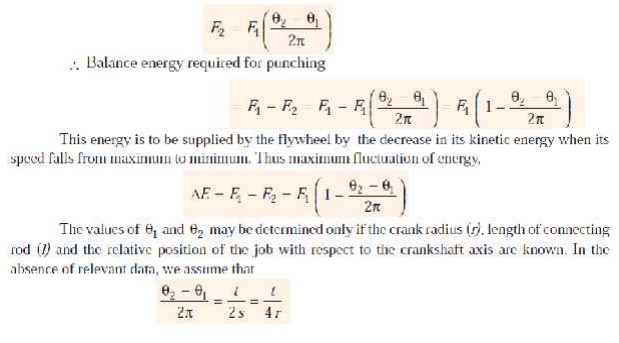

FLYWHEEL IN PUNCHING PRESS

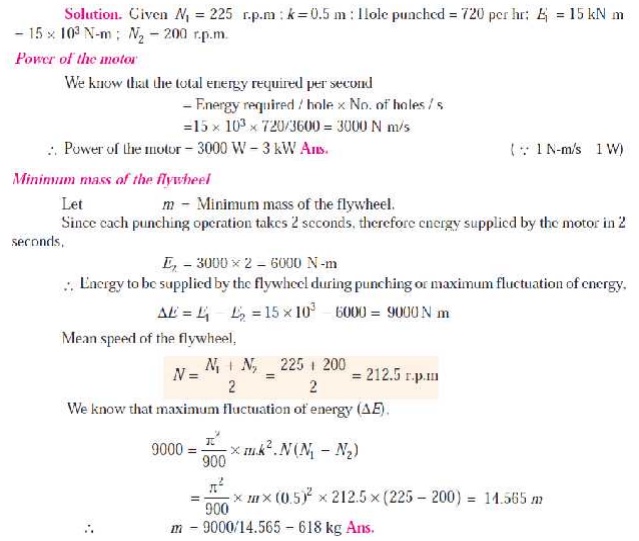

Q. A punching press is driven by a constant torque

electric motor. The press is provided with a flywheel that rotates at maximum speed of

225 r.p.m. The radius of gyration of the flywheel is 0.5 m. The press punches

720 holes per hour; each punching operation takes 2 second and requires 15 kN-m

of energy. Find the power of the motor and the minimum mass of the flywheel if

speed of the same is not to fall below 200 r. p. m.

Q. A machine punching 38 mm holes in 32 mm thick

plate requires 7 N -m of energy per sq. mm of sheared area, and punches one hole in

every 10 seconds. Calculate the power of the motor required. The mean speed of

the flywheel is 25 metres per second. The punch has a stroke of 100 mm.

Find the mass of the flywheel required, if the

total fluctuation of speed is not to exceed 3% of the mean speed. Assume that

the motor supplies energy to the machine at uniform rate.

Solution. Given : d = 38 mm ; t = 32 mm ; E1 = 7 N-m/mm2 of sheared area ; v

= 25 m/s ; s = 100 mm ; v1 ŌłÆ v2 = 3% v = 0.03 v

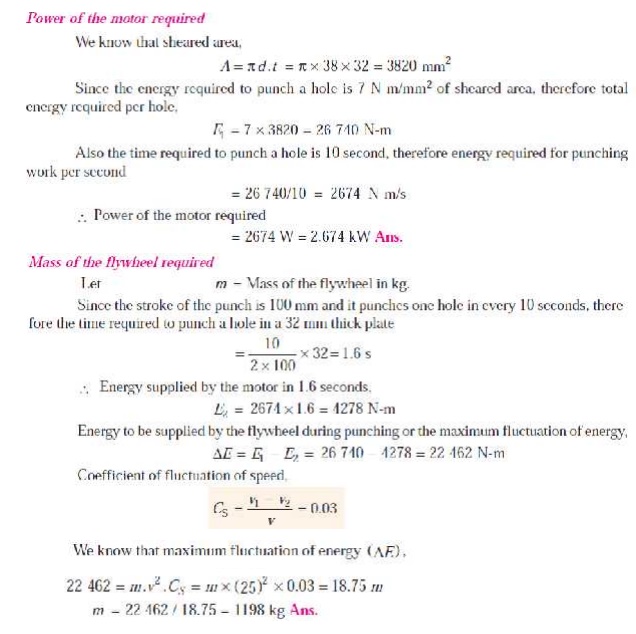

Q. A riveting machine is driven by a constant

torque 3 kW motor. The moving parts including the flywheel are equivalent to 150 kg

at 0.6 m radius. One riveting operation takes 1 second and absorbs 10 000 N-m

of energy. The speed of the flywheel is 300 r.p.m. before riveting. Find the

speed immediately after riveting. How many rivets can be closed per minute?

Solution. Given : P = 3 kW ; m

= 150 kg ; k = 0.6 m ; N1 = 300 r.p.m. or Žē1 = 2ŽĆ ├Ś 300/60 = 31.42 rad/s

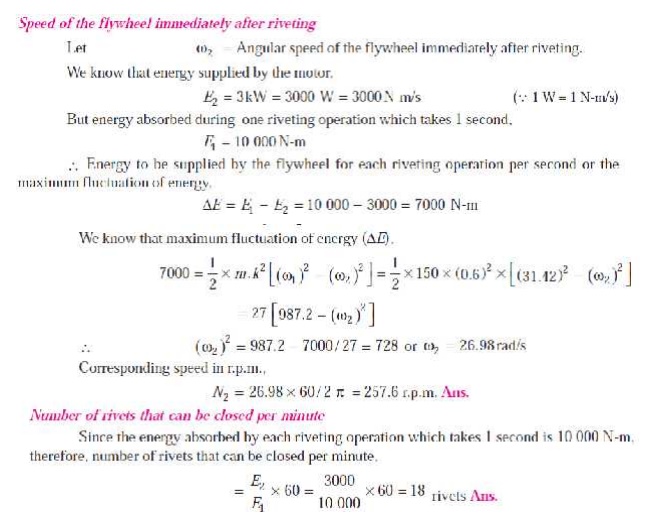

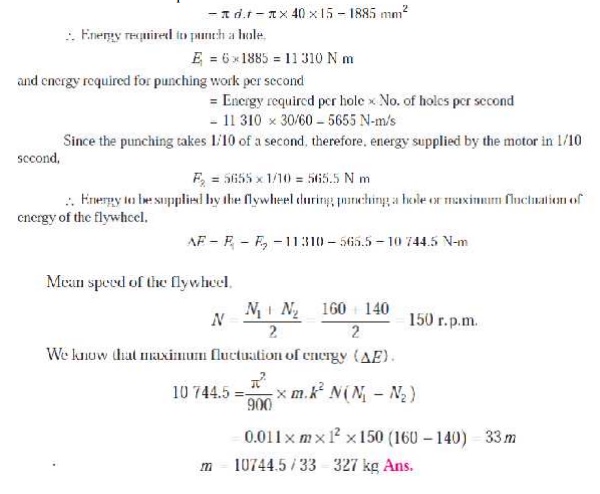

Q. A punching press is required to punch 40 mm

diameter holes in a plate of 15 mm thickness at the rate of 30 holes per minute. It

requires 6 N-m of energy per mm 2 of sheared area. If the punching

takes 1/10 of a second and the r.p.m. of the flywheel varies from 160 to 140,

determine the mass of the flywheel having radius of gyration of 1 metre.

Solution. Given: d = 40 mm; t

= 15 mm; No. of holes = 30 per

min.; Energy required = 6 N-m/mm2;

Time = 1/10 s = 0.1 s; N1 = 160

r.p.m.; N2 = 140 r.p.m.; k = 1m

We know

that sheared area per hole

CAM DYNAMICS:

Mechanism

provides a non-linear I/O relationship. Different mechanism like single or

multi-degree of freedom, intermittent motion mechanisms and linkages etc. have

different I/O Relationship. When we can not obtain a certain functions from the

well known mechanisms, we use a cam mechanism. It is a one degree of freedom

mechanism of two moving links. One is cam and the other is follower.

Rigid and elastic body cam system.

Analysis of eccentric cam

Problems on Cam ŌĆōfollower system.

Related Topics