Chapter: Business Science : Enterprise Resource Planning

Evolution of Enterprise Resource Planning

Evolution of Enterprise Resource Planning

Enterprise

resource planning (ERP) has evolved as a strategic tool, an outcome of over

four decades. This is because of continuous improvements done to the then

available techniques to manage business more efficiently and also with

developments and inventions in information technology field.

1 Pre Material Requirement Planning (MRP) stage

Prior to

1960s businesses generally relied on traditional ways of managing inventories

to ensure smooth functioning of the organizations. These theories are popularly

known as ‘Classical Inventory Management

or Scientific Inventory Control Methods’. Most popularly used among them

were Economic Order Quantity (EOQ); Bill of Material (BOM) etc. However these

systems had very limited scope.

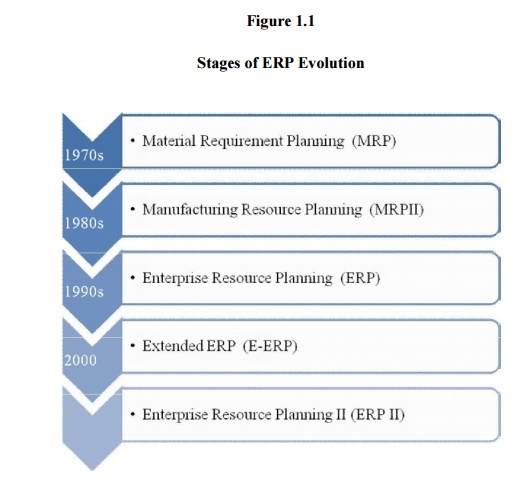

ERP

system has evolved from the Material Planning System of 1980’s. There are

various phases through which this evolution process has gone through. The

various phases of development of resource planning system in relation to time

and evolution of concept of ERP.

Figure 1.1

Stages of ERP Evolution

2. Material Requirement Planning (MRP)

MRP was

the fundamental concept of production management and control in the mid-1970s

and considered as the first stage in evolution of ERP. Assembly operations

involving thousands of parts such as automobile manufacture led to large

inventories. The need to bring down the large inventory levels associated with

these industries led to the early MRP systems that planned the order releases.

Such planned order releases ensured proper time phrasing and accurate planning

of the sub-assembly items, taking into account complex sub-assembly to assembly

relationships characterized by the Bill of Materials.

Example:

A typical

example is a bicycle manufacture. To manufacture 100 units of bicycles, one

needs 200 wheels, 100 foot-pedals, and several thousands of spokes. On a given

day, a plant may have 40 units of complete bicycles in stock, 57 units of

wheels, 43 units of foot-pedals and 879 units of spokes. If the plant is to

assemble 20 units of bicycles for the next 4 days of production, wheels and

spokes-is a non trivial problem. If the independent demand of the spare parts

is also to be taken into account, one can visualize the complexity of it.

A typical

automobile plant with hundreds, if not thousands of parts, has to face problems

that are in order of magnitude even more difficult. MRP systems address this

need. Using the processing power of computers, databases to store lead-times

and order quantities and algorithms to implement Bill-of-Material (BOM)

explosion, MRP systems brought considerable order into the chaotic process of

material planning in a discrete manufacturing operation.

Essentially

MRP addresses a single task in manufacturing alone. Material requirement

planning (MRP) system was adopted by firms for creation and maintenance of

master data and bill of material across all products and part within an

organization. MRP on the other hand was an outgrowth of bill of material (BOM)

processing, which is purchase order management that utilizes parts list

management and parts development.

3 Manufacturing Resources Planning II (MRP- II)

A natural

evolution from the first generation MRP systems was the manufacturing planning

systems MRP II that addressed the entire manufacturing function and not just a

single task within the manufacturing function. MRP II went beyond computations

of the materials requirement to include loading and scheduling. MRP II systems

could determine whether a given schedule of production was feasible, not merely

from material availability but also from other resource point of view.

Typically,

the resources considered from MRP II systems would include production

facilities, machine capacities and precedence sequences. The increased

functionality enabled MRP II systems provided a way to run the system in a

loop. First it was used to check the feasibility of a production schedule

taking into account the constraints; second to adjust the loading of the

resources, if possible, to meet the production schedules; third to plan the

materials using the traditional MRP II systems. Both MRP system and MRP II

systems were fairly successful in industry. Due to the power of information

systems-databases, algorithms and their integration, organizations did find

real support for efficiently managing the manufacturing function in the

eighties.

4 Enterprise Resource Planning (ERP)

The

nineties saw unprecedented global competition, customer focus and shortened

product life cycles. To respond to these demands corporations had to move

towards agile (quick moving) manufacturing of products, continuous improvements

of process and business process reengineering. This called for integration of

manufacturing with other functional areas including accounting, marketing,

finance and human resource development.

Activity-based

costing would not be possible without the integration of manufacturing and

accounting. Mass customization of manufacturing needed integration of marketing

and manufacturing. Flexible manufacturing with people empowerment necessitated

integration of manufacturing with the HRD function. In a sense the 1990s truly

called integration of all the functions of management. ERP systems are such

integrated information systems build to meet the information and decision needs

of an enterprise spanning all the functions of management4.

5 Extended ERP (E-ERP)

Further developments

in the enterprise resource planning system concept have led to evolution of

extended ERP (E- ERP) or web - enabled ERP. With globalization on one hand and

massive development in the internet technology on the other, need for web based

IT solution was felt. Thus E- ERP is development in the field of ERP which

involves the technology of Internet and World Wide Web (WWW) to facilitate the

functions of an organization around the web.

6 Enterprise Resource Planning II (ERP- II)

ERP II is

the advanced step of E-ERP. It is the software package which has strengthened

the original ERP package by included capabilities like customer relationship

management, knowledge management, workflow management and human resource

management. It is a web friendly application and thus addresses the issue of

multiple office locations.

7 ERP – A Manufacturing Perspective

ERP

systems evolved out of MRP and MRP II systems. MRP systems addressed the single

task of materials requirements planning. MRP II extended the scope to the

entire manufacturing function. The manufacturing industry traditionally had a

better climate to use computers. First of all the manufacturing community being

dominated by engineers had no computer phobia. Second the extensive use of

Computer Aided Drafting (CAD), Computer Aided Design (CAD) and Computer Aided

Manufacturing (CAM) had prepared the manufacturing function to use computers

well, in fact exceptionally well. In fact manufacturing engineers contributed

significantly to the theoretical computer science by way of contributions in

the areas of graphics, computational geometry, significant visualization,

feature recognition etc.

Large

corporations like General Motors (GM), Ford, Hewlett Packard (HP), and Digital

primarily viewed themselves as manufacturing companies until the 1980s.

Naturally complex MRP systems were considered the ultimate in enterprise

information systems. The investments in hardware and software to manage such

complex manufacturing solutions gave these systems a visibility unparalleled in

the industry. Compared to these systems accounting systems, financial systems

or personnel information systems were relatively inconsequential to the

organization.

With the

globalization of operations and the proliferation of computer networks, it was

important that the manufacturing organizations extend their information system

across the supply chain.

The

supplier’s information system spread across continents with complex

combinations of hardware and software need to be integrated. Similarly the

dealer-distributor network had to be integrated with the manufacturing

information systems. The reduction in product life cycle necessitated a quick

response manufacturing system that had its ears tuned to the market.

This

forced manufacturing information systems to have a tighter integration with

marketing information systems. The manufacturing flexibility had translated

into mass customization calling for further integration of information systems.

The opening up of several world economies including that of the Asian giants

like China and India, the emergence of trade blocks and consolidated markets

such as European Union paved the need for accounting and finance functions to

be tightly integrated with manufacturing functions. It was not sufficient

anymore just to manufacture and sell but organizations had to arrange for

finance, comply with complex trade restrictions, barriers, and quotas.

The

balance sheets needed to account for multiple currencies, multiple export

import rules and regulations, multiple accounting codes, practices, accounting

periods. This necessitated further

integration

of accounting and financial information systems with manufacturing systems. In

fact with large capacities built around the world particularly in Asian countries,

outsourcing and contract manufacturing became viable alternative even in the

high-tech industries like semi conductor manufacturing.

Suddenly

the need was for an Enterprise Information System that looks beyond the

manufacturing function to address inbound logistics, outbound logistics,

manufacturing, materials managements, project management, quality management,

accounting, finance, sales and personnel management. It was nearly impossible

to integrate individual modules of information systems. What was necessary was

a system that addressed the enterprise needs from the design stage. ERP systems

were the natural choice in this changed scenario.

Related Topics