Chapter: Environmental Biotechnology: Phytotechnology and Photosynthesis

Effluent treatment

Effluent treatment

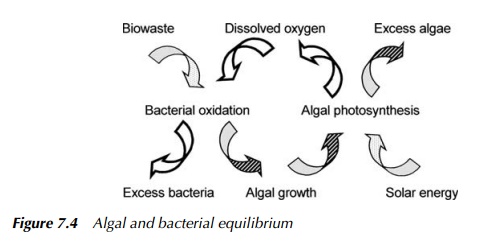

Algal effluent treatment systems work on the basis of functional

eutrophication and rely on a dynamic equilibrium between the autotrophic algae

themselves and the resident heterotophic bacteria, which establishes a

two-stage biodegradation/assimilation process, as shown in Figure 7.4. In

effect this is an ecological microcosm in which organic contaminants present in

the wastewater are biolog-ically decomposed by the aerobic bacteria, which make

use of oxygen provided by algal photosynthesis, while the algae grow using the

nutrients produced by this bacterial breakdown, and photosynthesise producing

more oxygen.

Though the process is

self-sustaining, it is also self-limiting and left to pro-ceed unchecked, will

result in the well-appreciated characteristic eutrophic stages leading to the

eventual death of all component organisms, since true climactic balance is

never achieved in the presence of continuously high additional nutri-ent

inputs. The removal of excess algal and bacterial biomass is, therefore, an

essential feature, vital to maintaining the system’s efficiency.

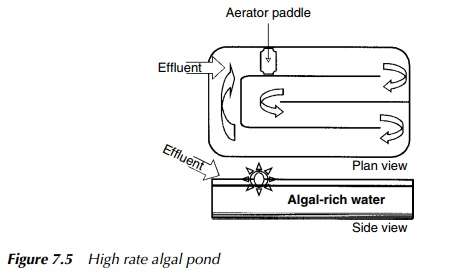

Of all the engineered algal

systems for effluent, the high rate algal pond (HRAP) is one of the most

efficient and represents a good illustration of this use of phytotechnology.

Figure 7.5 shows a typical example.

The system consists of a

bioreactor cell in the form of a relatively shallow reservoir, typically

between 0.2 – 0.6 metres deep, with a length to width ratio of 2:1 or more, the

idea being to produce a large surface area to volume ratio. The void is divided

with internal baffles forming walls, to create a channel through which the

effluent flows. A mechanically driven paddle at the end nearest to the effluent

input both aerates and drives the wastewater around the system.

These ponds are not sensitive to fluctuations in daily feed, either

in terms of quantity or quality of effluent, providing that it is fundamentally

of a kind suitable for this type of treatment. Consequently, they may be fed on

a continuous or intermittent basis. The main influences which affect the

system’s performance are the composition of the effluent, the efficiency of

mixing, the retention time, the availability and intensity of light, pond depth

and temperature. The latter two factors are particularly interesting since they

form logical constraints on the two groups of organisms responsible for the

system’s function, by affecting the autotrophe’s ability to photosynthesise and

the heterotrophe’s to respire. While a deeper cell permits greater resident

biomass, thus elevating the numbers of micro-organisms available to work on the

effluent, beyond a certain limit, the law of diminishing returns applies in

respect of light available to algae in the lower reaches. Warmer temperatures

increase metabolic activity, at least within reason,and the rate of

straightforward chemical reactions doubles per 10 ◦C rise, but at the same

time, elevated water temperatures have a reduced oxygen-carrying capacity which

affects the bacterial side of the equilibrium mentioned earlier. As with so

much of environmental biotechnology, a delicate balancing act is required.

After a suitable retention

period, which again depends on the character of the effluent, the design and

efficacy of the treatment pond and the level of clean-up required, the water is

discharged for use or returned to watercourses. Obviously, after a number of

cycles, algal and bacterial growth in a functionally eutrophic environment

would, as discussed earlier in the section, begin to inhibit, and then

eventually arrest, the biotreatment process. By harvesting the algal biomass,

not only are the contaminants, which to this point have been merely

biologically iso-lated, physically removed from the system, but also a local

population depression is created, triggering renewed growth and thus optimised

pollutant uptake. The biomass recovered in this way has a variety of possible

uses, of which compost-ing for ultimate nutrient reclamation is without doubt

the most popular, though various attempts have also been made to turn the algal

crop into a number of different products, including animal feed and insulating

material.

Related Topics