Chapter: Environmental Engineering : Water Treatment

Demineralization : Principles,Equipment, Operation, Advantages And Limitations

DEMINERALIZATION

Softening alone is insufficient for most high-pressure boiler

feedwaters and for many process streams, especially those used in the

manufacture of electronics equipment. In addition to the removal of hardness,

these processes require removal of all dissolved solids, such as sodium,

silica, alkalinity, and the mineral anions (Cl¯ , SO4²¯ , NO3¯

).

Demineralization of water is the

removal of essentially all inorganic salts by ion exchange. In this process,

strong acid cation resin in the hydrogen form converts dissolved salts into

their corresponding acids, and strong base anion resin in the hydroxide form

removes these acids. Demineralization produces water similar in quality to

distillation at a lower cost for most fresh

Principles

of Demineralization

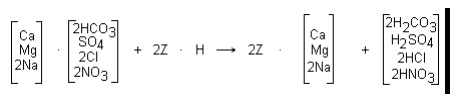

A demineralizer system consists

of one or more ion exchange resin columns, which include a strong acid cation

unit and a strong base anion unit. The cation resin exchanges hydrogen for the

raw water cations as shown by the following reactions:

A measure of the total concentration of the strong acids in

the cation effluent is the free mineral acidity (FMA). In a typical service run,

the FMA content is stable most of the time, as shown in Figure 8-8. If cation

exchange were 100% efficient, the FMA from the exchanger would be equal to the

theoretical mineral acidity (TMA) of the water. The FMA is usually slightly

lower than the TMA because a small amount of sodium leaks through the cation

exchanger. The amount of sodium leakage depends on the regenerant level, the

flow rate, and the proportion of sodium to the other cations in the raw water.

In general, sodium leakage increases as the ratio of sodium to total cations

increases.

As a cation exchange unit nears exhaustion, FMA in the

effluent drops sharply, indicating that the exchanger should be removed from

service. At this time the resin should be regenerated with an acid solution, which

returns the exchange sites to the hydrogen form. Sulfuric acid is normally used

due to its affordable cost and its availability. However, improper use of

sulfuric acid can cause irreversible fouling of the resin with calcium sulfate.

To prevent this occurrence, the sulfuric acid is usually

applied at a high flow rate (1 gpm per square foot of resin) and an initial

concentration of 2% or less. The acid concentration is gradually increased to

6-8% to complete regeneration.

Some installations use hydrochloric acid for regeneration.

This necessitates the use of special materials of construction in the

regenerant system. As with a sodium zeolite unit, an excess of regenerant

(sulfuric or hydrochloric acid) is required up to three times the theoretical dose.

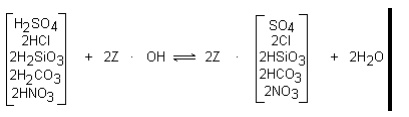

To complete the demineralization

process, water from the cation unit is passed through a strong base anion

exchange resin in the hydroxide form. The resin exchanges hydrogen ions for

both highly ionized mineral ions and the more weakly ionized carbonic and

silicic acids, as shown below:

The above reactions indicate that demineralization completely

removes the cations and anions from the water. In reality, because ion exchange

reactions are equilibrium reactions, some leakage occurs. Most leakage from

cation units is sodium. This sodium leakage is converted to sodium hydroxide in

the anion units. There-fore, the effluent pH of a two bed cation-anion demineralizer system is slightly alkaline.

The caustic produced in the anions causes a small amount of silica leakage. The

extent of leakage from the anions depends on the chemistry of the water being

processed and the regenerant dosage being used.

Demineralization using strong anion resins removes silica as

well as other dissolved solids. Effluent silica and conductivity are important

parameters to monitor during a demineralizer service run. Both silica and

conductivity are low at the end of the fast rinse, as shown in Figure 8-9.

When silica breakthrough occurs at the end of a service run,

the treated water silica level increases sharply. Often, the conductivity of

the water decreases momentarily, then rises rapidly. This temporary drop in

conductivity is easily explained. During the normal service run, most of the

effluent conductivity is attributed to the small level of sodium hydroxide

produced in the anion exchanger. When silica breakthrough occurs, the hydroxide

is no longer available, and the sodium from the cation exchanger is converted

to sodium silicate, which is much less conductive than sodium hydroxide. As

anion resin exhaustion progresses, the more conductive mineral ions break

through, causing a subsequent increase in conductivity.

When the end of a demineralizer run is detected, the unit must

be removed from service immediately. If the demineralizer is allowed to remain

in service past the breakpoint, the level of silica in the treated water can

rise above that of the influent water, due to the concentrating of silica that

takes place in the anion resin during the service run.

Strong base anion exchangers are regenerated with a 4% sodium

hydroxide solution. As with cation regeneration, the relatively high

concentration of hydroxide drives the regeneration reaction. To improve the

removal of silica from the resin bed, the regenerant caustic is usually heated

to 120 o F or to the temperature specified by the resin manufacturer. Silica

removal is also enhanced by a resin bed preheat step before the introduction of

warm caustic.

Equipment

and Operation

The equipment used for cation-anion demineralization is

similar to that used in zeolite softening. The primary difference is that the

vessels, valves, and piping must be made of (or lined with) corrosion-resistant

materials. Rubber and polyvinyl chloride (PVC) are commonly used for ion

exchange vessel linings. The controls and regenerant systems for demineralizers

are more complex, to allow for such enhancements as stepwise acid and warm

caustic regenerations.

Demineralizers are similar in operation to zeolite softeners.

The service flow rate guidelines for a demineralizer range from 6 to 10 gpm per

square foot of resin. Flow rates of over 10 gpm per square foot of resin cause

increased sodium and silica leakage with certain waters. Anion resin is much

lighter than cation resin. Therefore, the backwash flow rates for anion

exchange resins are much lower than those for cation resins, and anion resin

expansion is affected by the temperature of the water more than cation resin

expansion. The water used for each step of anion resin regeneration should be

free from hardness, to prevent precipitation of hardness salts in the alkaline

anion resin bed.

Continuous

conductivity instruments and silica analyzers are commonly used to monitor

anion effluent water quality and detect the need for regeneration. In some

instances, conductivity probes are placed in the resin bed above the underdrain

collectors to detect resin exhaustion before silica breakthrough into the

treated water occurs.

Advantages

and Limitations

Demineralizers can produce high-purity water for nearly every

use. Demineralized water is widely used for high pressure boiler feedwater and

for many process waters. The quality of water produced is comparable to

distilled water, usually at a fraction of the cost. Demineralizers come in a

wide variety of sizes. Systems range from laboratory columns that produce only

a few gallons per hour to systems that produce thousands of gallons per minute.

Like other ion exchange systems,

demineralizers require filtered water in order to function efficiently. Resin

foulants and degrading agents, such as iron and chlorine, should be avoided or

removed prior to demineralization. Anion resins are very susceptible to fouling

and attack from the organic materials present in many surface water supplies.

Some forms of silica, known as colloidal, or non-reactive, are not removed by a

demineralizer. Hot, alkaline boiler water dissolves the colloidal material,

forming simple silicates that are similar to those that enter the boiler in a

soluble form. As such, they can form deposits on tube surfaces and volatilize

into the steam.

Related Topics