Chapter: Environmental Engineering : Water Treatment

Dealkalization

DEALKALIZATION

Often, boiler or process operating conditions

require the removal of hardness and the reduction of alkalinity but not the

removal of the other solids. Zeolite softening does not reduce alkalinity, and

demineralization is too costly. For these situations, a dealkalization process

is used. Sodium zeolite/hydrogen zeolite (split stream) dealkalization,

chloride-anion dealkalization, and weak acid cation dealkalization are the most

frequently used processes.

Sodium

Zeolite/Hydrogen Zeolite (Split Stream) Dealkalization

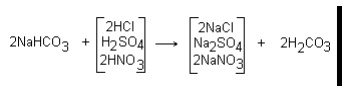

In a split stream dealkalizer, a portion of the raw

water flows through a sodium zeolite softener. The remainder flows through a

hydrogen-form strong acid cation unit (hydrogen zeolite). The effluent from the

sodium zeolite is combined with the hydrogen zeolite effluent. The effluent

from the hydrogen zeolite unit contains carbonic acid, produced from the raw

water alkalinity, and free mineral acids. When the two streams are combined,

free mineral acidity in the hydrogen zeolite effluent converts sodium carbonate

and bicarbonate alkalinity in the sodium zeolite effluent to carbonic acid as

shown below:

Carbonic acid is unstable in water. It forms carbon

dioxide gas and water. The blended effluents are sent to a decarbonator or

degasser, where the carbon dioxide is stripped from the water by a

countercurrent stream of air.

The desired level of blended water alkalinity can be

maintained through control of the percentage of sodium zeolite and hydrogen

zeolite water in the mixture. A higher percentage of sodium zeolite water

results in higher alkalinity, and an increased percentage of hydrogen zeolite

water reduces alkalinity.

In addition to reducing alkalinity, a split stream

dealkalizer reduces the total dissolved solids of the water. This is important

in high alkalinity waters, because the conductivity of these waters affects the

process and can limit boiler cycles of concentration.

Sodium

Zeolite/Chloride Anion Dealkalization

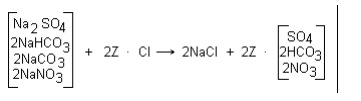

Strong base anion resin in the chloride form can be

used to reduce the alkalinity of a water. Water flows through a zeolite

softener and then an anion unit, which replaces the carbonate, bicarbonate,

sulfate, and nitrate ions with chloride ions as shown in these reactions:

The chloride anion dealkalizer reduces alkalinity by

approximately 90% but does not reduce total solids. When the resin nears

exhaustion, treated water alkalinity increases rapidly, signaling the need for

regeneration.

The zeolite softener is regenerated as previously

described. In addition, the anion resin is also regenerated with a sodium

chloride brine that returns the resin to the chloride form. Frequently, a small

amount of caustic soda is added to the regenerant brine to enhance alkalinity

removal.

Weak

Acid Cation Dealkalization

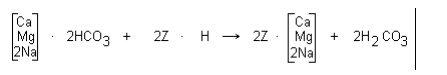

Another method of dealkalization uses weak acid

cation resins. Weak acid resins are similar in operation to strong acid cation

resins, but only exchange for cations that are associated with alkalinity, as

shown by these reactions:

where Z represents the resin. The carbonic acid (H2CO3)

formed is removed by a decarbonator or degasser as in a split stream system.

The ideal influent for a weak acid cation system has

a hardness level equal to the alkalinity (both expressed in ppm as CaCO3).

In waters that are higher in alkalinity than hardness, the alkalinity is not

removed to its lowest level. In waters containing more hardness than

alkalinity, some hardness remains after treatment. Usually, these waters must

be polished by a sodium zeolite softener to remove hardness. During the initial

portion of a weak acid cation service run (the first 40-60%) some cations

associated with mineral anions exchange, producing small amounts of mineral

acids in the effluent. As the service cycle progresses, alkalinity appears in

the effluent. When the alkalinity in the effluent exceeds 10% of the influent

alkalinity, the unit is removed from service and regenerated with a 0.5%

sulfuric acid solution. The concentration of regenerant acid should be kept

below 0.5-0.7%, to prevent calcium sulfate precipitation in the resin. Weak

acid cation resin exchange is very efficient. Therefore, the amount of acid required

is virtually equal (chemically) to the amount of cations removed during the

service cycle.

If

the materials of construction for the down-stream equipment or overall process

cannot tolerate the mineral acidity present during the initial portions of the

service cycle, a brine solution is passed through the regenerated weak acid

resin prior to the final rinse. This solution removes the mineral acidity

without a significant impact on the quality or length of the subsequent run.

Equipment

used for a weak acid cation dealkalizer is similar to that used for a strong

acid cation exchanger, with the exception of the resin. One variation of the

standard design uses a layer of weak acid resin on top of strong acid cation

resin. Because it is lighter, the weak acid resin remains on top. The layered

resin system is regenerated with sulfuric acid and then with sodium chloride

brine. The brine solution converts the strong acid resin to the sodium form.

This resin then acts as a polishing softener.

Direct Acid Injection

In

the process of direct acid injection and decarbonation, acid is used to convert

alkalinity to carbonic acid. The carbonic acid dissociates to form carbon

dioxide and water and the carbon dioxide is removed in a decarbonator. The use

of an acid injection system should be approached with caution, because an acid

overfeed or a breakdown in the pH control system can produce acidic feedwater,

which corrodes the iron surfaces of feedwater systems and boilers. Proper pH

monitoring and controlled caustic feed after decarbonation are required.

Advantages and

Limitations of Dealkalization Systems

Ion

exchange dealkalization systems produce hardness-free, low-alkalinity water at

a reasonable cost, and with a high degree of reliability. They are well suited

for processing feedwater for medium-pressure boilers, and for process water for

the beverage industry. Split stream and weak acid cation systems also reduce

the total dissolved solids. In addition to these advantages, the following

disadvantages must be considered:

·

dealkalizers do not remove all of the

alkalinity and do not affect the silica content of a water

·

dealkalizers require the same influent

purity as other ion exchange processes; filtered water that is low in potential

foulants must be used

·

the water produced by a dealkalization

system using a forced draft decarbonator becomes saturated with oxygen, so it

is potentially corrosive

Related Topics