Chapter: Basic Electrical : Electrical Machines

DC Generator

DC Generator

DC Generator:

To change the Simple Generator into a

direct-current generator, two things must be done:(1) The current must be

conducted from the rotating loop of wire(2) The current must be made to move in

only one direction. A device called a commutator performs both tasks.

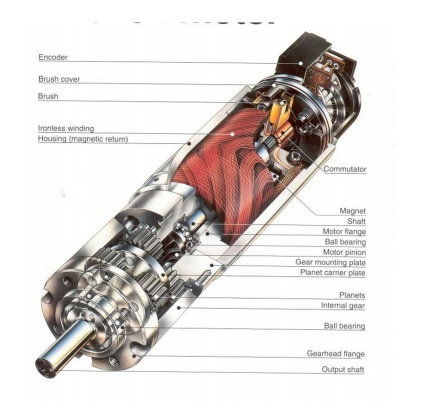

DC generator construction:

What is

Generator?

An electrical generator is a

device that converts mechanical energy to electrical energy, generally using electromagnetic

induction. The source of mechanical energy may be a reciprocating or turbine steam

engine, water falling through a turbine or waterwheel, an internal combustion

engine, a wind turbine, a hand crank, or any other source of mechanical energy.

The

Dynamo was the first electrical generator capable of delivering power for

industry. The dynamo uses electromagnetic principles to convert mechanical

rotation into an alternating electric current. A dynamo machine consists of a

stationary structure which generates a strong magnetic field, and a set of

rotating windings which turn within that field. On small machines the magnetic

field may be provided by a permanent magnet; larger machines have the magnetic

field created by electromagnets.

The

energy conversion in generator is based on the principle of the production of

dynamically induced e.m.f. whenever a conductor cuts magneticic flux,

dynamically induced e.m.f is produced in it according to Faraday's Laws of

Electromagnetic induction. This e.m.f causes a current to flow if the conductor

circuit is closed. Hence, two basic essential parts of an electrical generator

are (i) a magnetic field and (ii) a conductor or conductors which can so move

as to cut the flux.

Here is the construction diagram

of dc generator:

Generator

Construction:

Simple

loop generator is having a single-turn rectangular copper coil rotating about

its own axis in a magnetic field provided by either permanent magnet or electro

magnets. In case of without commutator the two ends of the coil are joined to

slip rings which are insulated from each other and from the central shaft.Two

collecting brushes (of carbon or copper) press against the slip rings.Their

function is to collect the current induced in the coil. In this case the

current waveform we obtain is alternating current ( you can see in fig). In

case of with commutator the slip rings are replaced by split rings.In this case

the current is unidirectional.

Components of a generator:

Yoke: Yoke is a outer frame. It serves two purposes.

(i) It

provides mechanical support for the poles and acts as a protecting cover for

the whole machine and

(ii) It

carries the magnetic flux produced by the poles.

In small

generators where cheapness rather than weight is the main consideration, yokes

are made of cast iron. But for large machines usually cast steel or rolled

steel is employed. The modern process of forming the yoke consists of rolling a

steel slab round a cylindrical mandrel and then welding it at the bottom. The

feet and the terminal box etc., are welded to the frame afterwards. Such yokes

possess sufficient mechanical strength and have high permeability.

Rotor: In its simplest form, the rotor consists of a single loop of wire

made to rotate within a magnetic field. In practice, the rotor

usually consists of several coils of wire wound on an armature.

Armature: The armature is a cylinder of laminated iron mounted on an axle.

The axle is carried in bearings mounted in the

external structure of the generator. Torque is applied to the axle to make the

rotor spin.

Coil: Each coil usually consists of many turns of copper wire wound on

the armature. The two ends of each coil are connected

either to two slip rings (AC) or two opposite bars of a split-ring commutator

(DC).

Stator: The stator is the fixed part of the

generator that supplies the magnetic field in which the coils rotate. It may consist of two

permanent magnets with opposite poles facing and shaped to fit around the

rotor. Alternatively, the magnetic field may be provided by two electromagnets.

Field

electromagnets: Each electromagnet consists of a coil

of many turns of copper wire wound on a soft iron core. The

electromagnets are wound, mounted and shaped in such a way that opposite poles

face each other and wrap around the rotor.

Brushes: The brushes are carbon blocks that maintain contact with the ends

of the coils via the slip rings (AC) or the split-ring

commutator (DC), and conduct electric current from the coils to the external

circuit.

Principle of operation:

DC generator converts mechanical energy into

electrical energy. when a conductor move in a magnetic field in such a way

conductors cuts across a magnetic flux of lines and emf produces in a generator

and it is defined by faradays law of electromagneticinduction :emf causes

current to flow if the conductor circuit is closed.

Applications of DC generator:

1. Shunt

generators are extensively used for general light and power supply, and for

charging of batteries, since, in conjunction with a field regulator, a constant

terminal voltage can be maintained at all loads.

2. Series

generators are mainly used as animation boosters in dc transmission system, in

order to compensate for the drop of voltage due to the resistance of

transmission conductors.

3. Over-compounded

generators find use in dc transmission, since it is possible to keep on a

constant voltage at the load end, by generating a larger voltage so as to

overcome the line drop.

Related Topics