Chapter: Basic Electrical : Electrical Machines

DC Motor

DC Motor

DC Motor:

A DC

motor is a device which converts electrical energy into mechanical energy.D.C.

motors are motors that run on Direct Current from a battery or D.C. power

supply. Direct Current is the term used to describe electricity at a constant

voltage. A.C. motors run on Alternating Current, which oscillates with a fixed

cycle between a positive and negative value. Electrical outlets provide A.C.

power.

In a brushed

DC motor, the brushes make mechanical contact with a set of electrical contacts

provided on a commutator secured to an armature, forming an electrical circuit

between the DC electrical source and coil windings on the armature. As the

armature rotates on an axis, the stationary brushes come into contact with

different sections of the rotating commutator.

Permanent

magnet DC motors utilize two or more brushes contacting a commutator which

provides the direct current flow to the windings of the rotor, which in turn

provide the desired magnetic repulsion/attraction with the permanent magnets

located around the periphery of the motor.

The

brushes are conventionally located in brush boxes and utilize a U-shaped spring

which biases the brush into contact with the commutator. Permanent magnet

brushless dc motors are widely used in a variety of applications due to their

simplicity of design, high efficiency, and low noise. These motors operate by

electronic commutation of stator windings rather than the conventional

mechanical commutation accomplished by the pressing engagement of brushes

against a rotating commutator.

A

brushless DC motor basically consists of a shaft, a rotor assembly equipped

with one or more permanent magnets arranged on the shaft, and a stator assembly

which incorporates a stator component and phase windings. Rotating magnetic

fields are formed by the currents applied to the coils.

The

rotator is formed of at least one permanent magnet surrounded by the stator,

wherein the rotator rotates within the stator. Two bearings are mounted at an

axial distance to each other on the shaft to support the rotor assembly and

stator assembly relative to each other. To achieve electronic commutation,

brushless dc motor designs usually include an electronic controller for

controlling the excitation of the stator windings.

How DC motors work?

There are

different kinds of D.C. motors, but they all work on the same principles.When a

permanent magnet is positioned around a loop of wire that is hooked up to a

D.C. power source, we have the basics of a D.C. motor. In order to make the

loop of wire spin, we have to connect a battery or DC power supply between its

ends, and support it so it can spin about its axis. To allow the rotor to turn

without twisting the wires, the ends of the wire loop are connected to a set of

contacts called the commutator, which rubs against a set of conductors called

the brushes. The brushes make electrical contact with the commutator as it

spins, and are connected to the positive and negative leads of the power

source, allowing electricity to flow through the loop. The electricity flowing

through the loop creates a magnetic field that interacts with the magnetic field

of the permanent magnet to make the loop spin.

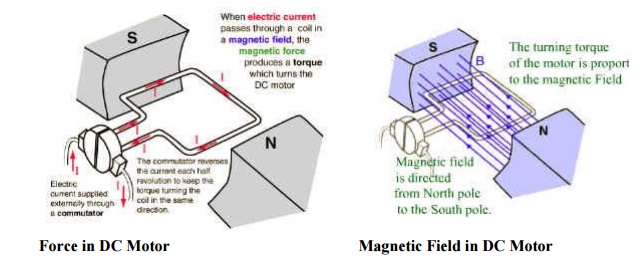

Principles of Operation:

It is

based on the principle that when a current-carrying conductor is placed in a

magnetic field, it experiences a mechanical force whose direction is given by

Fleming's Left-hand rule and whose magnitude is given by

Force, F

= B I l newton

Where B

is the magnetic field in weber/m2.

I is the

current in amperes and

l is the

length of the coil in meter.

The

force, current and the magnetic field are all in different directions.

If an

Electric current flows through two copper wires that are between the poles of a

magnet, an upward force will move one wire up and a downward force will move

the other wire down.

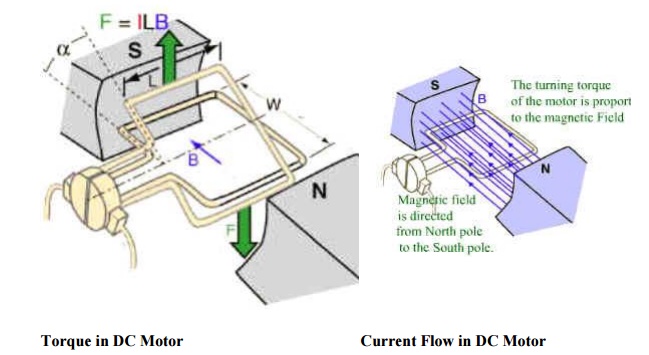

Torque in DC Motor Current

Flow in DC Motor

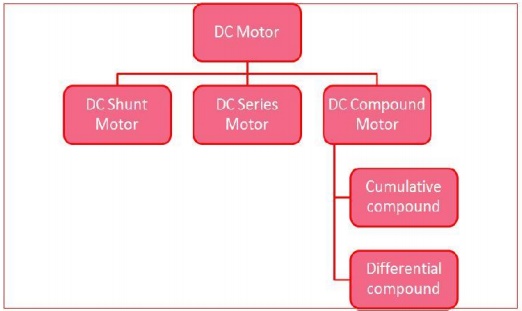

Classification of motor:

DC motors

are more common than we may think. A car may have as many as 20 DC motors to

drive fans, seats, and windows. They come in three different types, classified

according to the electrical circuit used. In the shunt motor, the armature and

field windings are connected in parallel, and so the currents through each are

relatively independent. The current through the field winding can be controlled

with a field rheostat (variable resistor), thus allowing a wide variation in

the motor speed over a large range of load conditions. This type of motor is

used for driving machine tools or fans, which require a wide range of speeds.

In the

series motor, the field winding is connected in series with the armature

winding, resulting in a very high starting torque since both the armature

current and field strength run at their maximum. However, once the armature

starts to rotate, the counter EMF reduces the current in the circuit, thus

reducing the field strength. The series motor is used where a large starting

torque is required, such as in automobile starter motors, cranes, and hoists.

The

compound motor is a combination of the series and shunt motors, having parallel

and series field windings. This type of motor has a high starting torque and

the ability to vary the speed and is used in situations requiring both these

properties such as punch presses, conveyors and elevators.

DC motor advantages:

Easy to

understand design

Easy to

control speed

Easy to

control torque

Simple,

cheap drive design

Related Topics