Chapter: Special Electrical Machines : Permanent Magnet Brushless D.C. Motors

Constructional Features of BLPM Motors

CONSTRUCTIONAL FEATURES OF BLPM

MOTORS

1. Construction

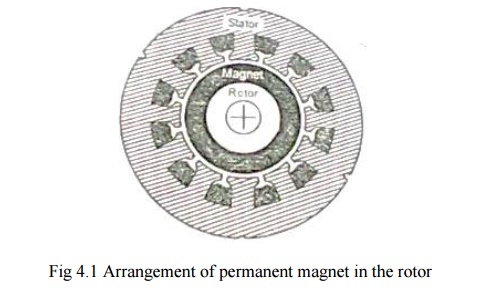

The

stator of the BLPM dc motor is made up of silicon steel stampings with slots in

its interior surface. These slots accommodate either a closed or opened

distributed armature winding usually it is closed. This winding is to be wound

for a specified number of poles. This winding is suitably connected to a dc supply

through a power electronic switching circuitry (named as electronic

commutator).

Rotor is

made of forged steel. Rotor accommodates permanent magnet. Number of poles of

the rotor is the same as that of the stator. The rotor shaft carries a rotor

position sensor. This position sensor provides information about the position

of the shaft at any instant to the controller which sends suitable signals to

the electronic commutator.

2. Merits and Demerits

Merits

v There is

no field winding. Therefore there is no field cu loss.

v The

length of the motor is less as there is no mechanical commutator.

v Size of

the motor becomes less.

v It is

possible to nave very high speeds.

v It is

self-starting motor. Speed can be controlled.

v Motor can

be operated in hazardous atmospheric condition.

v Efficiency

is better.

Demerits

v Field

cannot be controlled.

v Power

rating is restricted because of the maximum available size of permanent

magnets.

v A rotor

position sensor is required.

v A power

electronic switch circuitry is required.

3. Comparison of brushless dc

motor relative to induction motor drives

v In the

same frame, for same cooling, the brushless PM motor will have better

efficiency and p.f and therefore greater output. The difference may be in the

order of 20 ŌĆō 50% which is higher.

v Power

electronic converter required is similar in topology to the PWM inverters used

in induction motor drives.

v In case

of induction motor, operation in the weakening mode is easily achieved

providing a constant power capability at high speed which is difficult in BLPM

dc motor.

v PM

excitation is viable only in smaller motors usually well below 20 kw also

subject to speed constraints, In large motors PM excitation does not make sense

due to weight and cost.

4.

Commutator and brushes arrangement

Because of the hetropolar magnetic field in the air

gap of dc machine the emf induced in the armature conductors is alternating in

nature. This emf is available across brushes as unidirectional emf because of

commutator and brushes arrangement.

The dc current passing through the brushes is so

distributed in the armature winding that unidirectional torque is developed in

armature conductor.

A dc current passing through the brushes because of

commutator and brushes action, always sets up a mmf whose axis is in quadrature

with the main field axis, irrespective of the speed of the armature.

5. Construction of Mechanical

Commutator

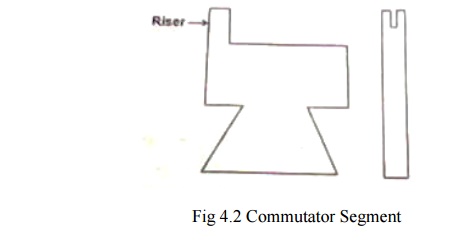

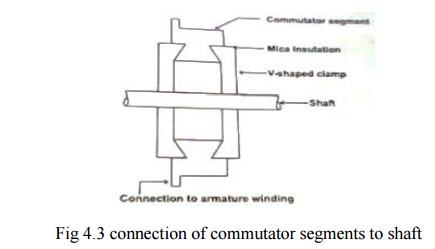

Commutator Segment

Commutator

is made up of specially shaped commutator segments made up of copper. These

segments are separated by thin mica sheets (ie) Insulation of similar shape.

The commutator segments are tapered such that when assembled they form a

cylinder.

These

segments are mechanically fixed to the shaft using V ŌĆō shaped circular steel

clamps, but are isolated electrically from the shaft using suitable insulation

between the clamps and the segment.

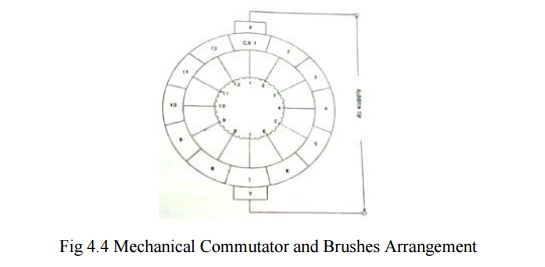

6. Mechanical Commutator and

Brushes Arrangement

It

represents a case with 2poles and 12 commutator segments.

To start

with the brush X contacts with CSI and brush Y with 7.A dc supply is connected

across the brushes X and Y. The dc current I passes through brush X,CSI,tapping

1,tapping

7and brush Y. There are two armature parallel paths between tappingŌĆśs 1 and

7.the current passing through the armature winding aets up a magneto motive

force whose axis is along the axes of tapping 7 and 1 of the brush axes Y and

X.

Allow the

armature to rotate by an angle in a counter clockwise direction. Then the brush

X contacts CS2 and the tappingŌĆśs a and the brush Y. Contact CS8 and tapping

8.The dc current passes through the tappingŌĆśs 2 and 8 there are two parallel

paths.

(i)

2 ŌĆō 3 ŌĆō 4 ŌĆō 5 ŌĆō 6 ŌĆō 7 ŌĆō 8

(ii)

2 ŌĆō 1 ŌĆō 12 ŌĆō 11 ŌĆō 10 ŌĆō 9 ŌĆō 8

Now the

mmf set up by the armature winding is form tapping 8 to 2 along the brush axis

YX Thus the armature mmf direction is always along the brush axis YX, even

though the current distribution in the armature winding gets altered.

In a

normal dc machine brushes are kept in the interpolar axis. Therfore, the axis

of the armature mmf makes an angle 90˚elec with the main field axis.

The

function of commutator and brushes arrangement in a conventional dc machine is

to set up an armature mmf always in quadrature with the main field mmf

respectively of the speed of rotation of the rotor.

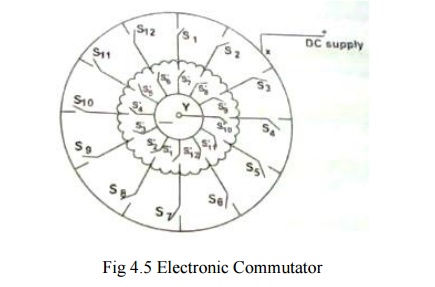

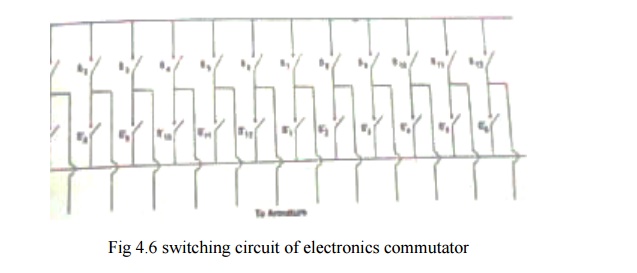

7. Electronic commutator

The armature winding which is in the stator has 12 tappingŌĆśs. each tapping is connected to the positive of the dc supply node and through 12 switches designated as S1 ,S2,ŌĆ”.S12 and negative of the supply at node Y through switches SŌĆś1,SŌĆś2,ŌĆ”ŌĆ”.SŌĆś12.

When S1

and SŌĆś1 are closed the others are in open position, the dc supply is given to

the trappings 1 and 7.there are two armature parallel path.

(i)

1 ŌĆō 2 ŌĆō 3 ŌĆō 4 ŌĆō 5 ŌĆō 6 ŌĆō 7

(ii)

1 ŌĆō 12 ŌĆō 11 ŌĆō 10 ŌĆō 9 ŌĆō 8 ŌĆō 7

They set

up armature mmf along the axis 7 to 1.

After a

small interval S1 and SŌĆś1 are kept open and S2 and SŌĆś2 are closed. Then dc

current passes from tapping 2 to 8 sets up mmf in the direction 8 ŌĆō 2.

Thus by

operating the switch in a sequential manner it is possible to get a revolving

mmf in the air gap. The switches S1 to S12 and SŌĆś1 to SŌĆś12 can be replaced by

power electronic switching devices such as SCRŌĆśs MOSFETŌĆśs IGBTŌĆśs, power

transistor etc.

When

SCRŌĆśs are used suitable commutating circuit should be included. Depending upon

the type of forced commutated employed, each switch requires on or two SCRs and

other commutating devices. As number of devices is increased, the circuit

becomes cumbersome.

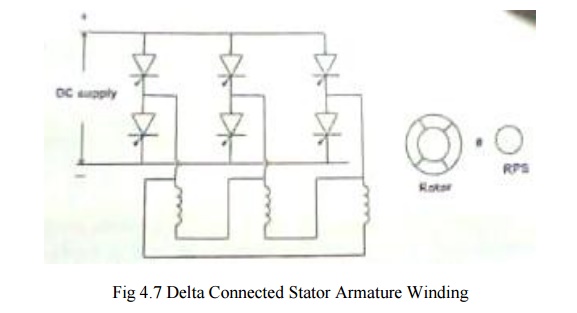

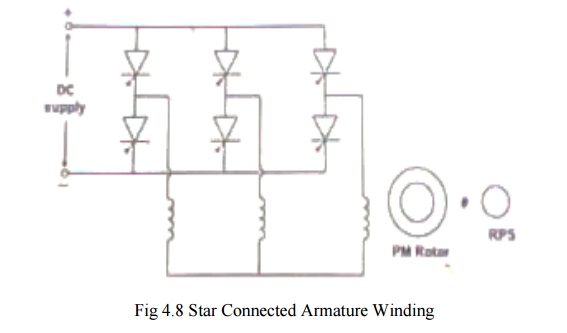

For

normal electronic commutator, usually six switching devices are employed. Then

the winding should have three tappingŌĆśs. Therefore the winding can be connected

either in star or in delta.

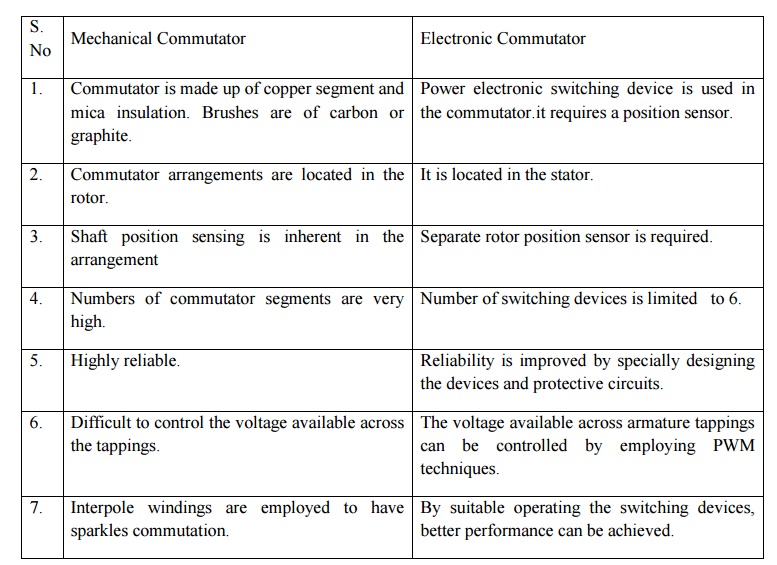

8. Comparison between mechanical

Commutator and brushes and Electronic Commutator

Related Topics