Chapter: Civil : Prefabricated Structures : Prefabricated Components

Construction of roof and floor walls

Construction

of roof and floor walls

These are load bearing structures having curved

surface.The advantage of shells is that it provides large column free area for

the monolithic construction.The cost of shuttering & scaffolding is very

high but if manufactured in a precast factory in large scale.The production

cosh can be considerably reduced.

The shell structure can have ribs in the centre

& provided with curved membranelikee roof.The shells built of precast

members used in the construction of industrial buildings are many.The thickness

of shell varies from 2 to 10cm.Some precast shell,,s are produced with

dimensions which are very difficult to transport.To avoid such difficulty large

size shells are precast near to the restting or construction place.

The

transportable or small size shell members can be precast in factories & these

are transported to the site.Examples:Barrel shells,Saddle or hyperboloid

shells.cupola or paraboloid shells.

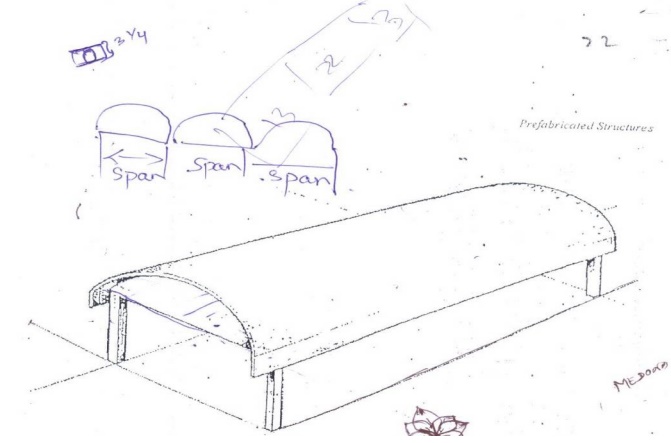

a.Single

barrel:

The structure above is a single barrel with edge

beams.The shell has been allowed to project beyond the edge of the stiffener in

order to show the shape of the shell.Stiffeners are required at columns.They do

not necessarily have to be complete diaphragms but may be arches with a

horizontal tie.The thickness is based on design of a slab element,the thickness

of the barrel shell is usually based on the minimum thickness required for

covering the steel for fireproofing,plus the space required for three layers of

bars,plus some space for tolerance.If these bars are all half inch rounds,a

practical minimum would be 3 ¼ inches.Near the supports the thickness may be

greater for containing the larger longitudinal bars.

If more than one barrel is placed side by side,the

structure is a multiple barrel structure & if more than one span,it is

called as multiple

span

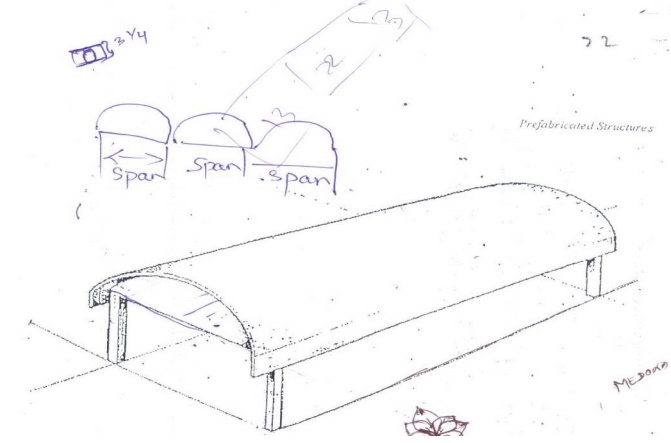

structure. Multiple barrel structure:

This structure shows a multiple barrel with

vertical edge beams at the outside edges.The stiffeners have been place over a

roof.The advantage of having the stiffeners on top is that there are no

interruptions to the space inside the shell so both the inside appearance &

the utility are better.The movable formwork may be used which will slide with

little decentering lengthwise of the shell.

The multiple span structure should have an

occasional expansion joint to reduce shrinkage & thermal stresses.This can

be accomplished by cantilevering half the span from eachadjacent stiffener.A

small upturned rib placed oon each side of the joint & accordion type sheet

metal flashing is arranged to prevent roof leakage.

The

maximum spans for this type shell are again limited by the geometry off the

cros section .Assuming the maximum width of barrel to be 50 feet & maximum

end slope to be 45 o ,the rise would be about

14 feet,the maximum span would be in the order of 150 feet.

North light shells:

This type of shell structure is used to provide large areas of

north light windows for factories requiring excellent natural lighting.The

windows may be slanting or may be vertical.The member at the bottom forms a

drainage trough with the curved shell & materially assists in stiffening

the structure. The effective depth of the shell is not the vertical distance

between the two ends but is morely represented b the depth if the shellis laid

flat with the ends of the circle on the same horizontal line.The spans for the

north light shell must be rather small in

comparison to the vertical depth of construction.The edges of

adjacent shalls should be tied together by concrete struts serving as mullions

between the window glazing.

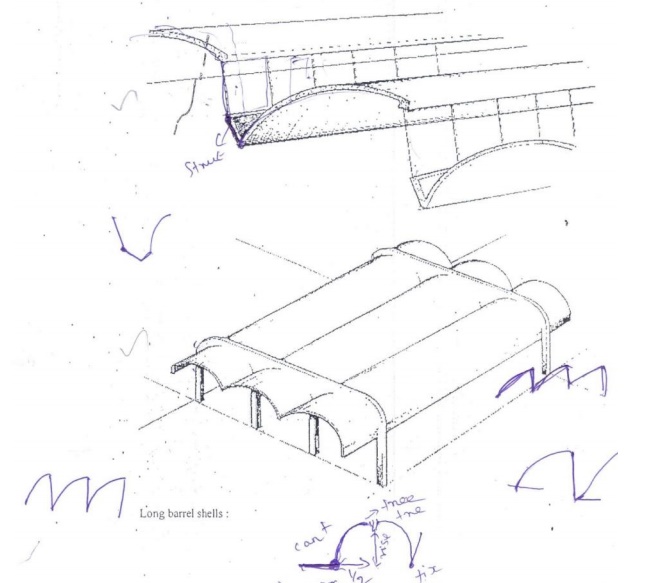

Long

barrel shell:

Long

barrel shell obtained hen the semicircle or a segment of same is translated

along the longitudinal axis.

Generally used for shed for industrially purpose

& buildings for large column free areas.Generally the prefabricated barrels

off sizes 3.5 to 5m & 10m long with edge beams having thickness of 60mm.The

thickness of the shell should not be more than 40mm.The dimension of these

members were finally limited by the load carrying capacity of the available hoisting

machines using the girder system built of precast prestressed trusses with

parallel chords,areas having a span of even more than 15m can be covere with

barrel shell

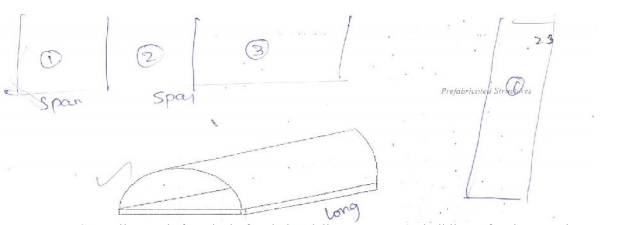

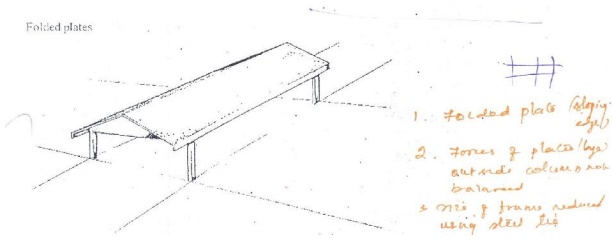

Folded

plate:

A folded plate structure with 3 segments for each barrel.The

forces from the reactions of the sloping plates on these rigid frames will be

quire large and at an outside column they will not be balanced by thrusts from

the adjacent plates.The size of the frames may be reduce by using a steel tie

between the tops of the columns.The dimensions of the plate are dependent on

both the with of the barrel & on the span.The depth of the shell should be

about 0.10 timess the span & the maximum slope of a plate should not be

greater than 40 o .For example,assume that

the span is 60feet & the baywidth is 24 feet.The depth of the shell should

be about 6 feet & the horizontal width of each plate with a 3 segment plate

should be about 8 feet.The lope of the plate is 6/8,which is about ![]() 37 o & is

satisfactory.The thickness of plate could be about 3 ½ inches.The principle

components in a folded

37 o & is

satisfactory.The thickness of plate could be about 3 ½ inches.The principle

components in a folded

plate consist of 1.inclined plate 2.edge plate which must be

used to wide plate.3.Stiffeners to carry the loads to the supports & to

hold the plate.4.Column to support the structure in the air.

Related Topics