Chapter: Mechanical : Maintenance Engineering : Condition Monitoring

Condition Monitoring

Condition Monitoring

Condition

monitoring is the process of monitoring a parameter of condition in machinery,

such that a significant change is indicative of a developing failure.

It is a

major component of predictive maintenance. The use of conditional monitoring

allows maintenance to be scheduled, or other actions to be taken to avoid the

consequences of failure, before the failure occurs.

Nevertheless,

a deviation from a reference value (e.g. temperature or vibration behavior)

must occur to identify impeding damages

Predictive Maintenance does not

predict failure.

Machines with defects are more at risk of failure than defect

free machines. Once a defect has been identified, the failure process has

already commenced and CM systems can only measure the deterioration of the

condition.

Intervention

in the early stages of deterioration is usually much more cost effective than

allowing the machinery to fail. Condition monitoring has a unique benefit in

that the actual load, and subsequent heat dissipation that represents normal

service can be seen and conditions that would shorten normal lifespan can be

addressed before repeated failures occur.

Serviceable machinery includes rotating equipment and

stationary plant such as boilers and heat exchangers.

Methods Of Cm

1.

Screen monitoring records video or static images

detailing the contents, or screen capture, of the entire [video display] or the

content of the screen activity within a particular program or computer

application. Monitoring tools may collect real time video, accelerated or

[time-lapse] video or screen shots, or may take video or still image captures

at regular intervals (e.g., once every 4 minutes). They may collect images

constantly or only collect information while the user is interacting with the

equipment (e.g., capturing screens when the mouse or keyboard is active).

2.

Data monitoring tracks the content of and changes

to files stored on the local [hard drive] or in the user's "private"

network share.

3.

Keystroke monitoring (e.g., number of keystrokes

per minute) may track the performance of keyboard-intensive work such as word

processing or data entry. Keystroke logging captures all keyboard input to

enable the employer to monitor anything typed into the monitored machine.

4.

Idle time monitoring keeps track of time when the

employee is away from the computer or the computer is not being actively used.

Benefits

o

Screen monitoring records video or static images

detailing the contents, or screen capture, of the entire [video display] or the

content of the screen activity within a particular program or computer

application.

o

Monitoring tools may collect real time video,

accelerated or [time-lapse] video or screen shots, or may take video or still

image captures at regular intervals (e.g., once every 4 minutes).

o

They may collect images constantly or only collect

information while the user is interacting with the equipment (e.g., capturing

screens when the mouse or keyboard is active).

o

Data monitoring tracks the content of and changes

to files stored on the local [hard drive] or in the user's "private"

network share.

o

Keystroke monitoring (e.g., number of keystrokes

per minute) may track the performance of keyboard-intensive work such as word

processing or data entry. Keystroke logging captures all keyboard input to

enable the employer to monitor anything typed into the monitored machine.

Idle time

monitoring keeps track of time when the employee is away from the computer or

the computer is not being actively used.

Load Testing

o

Load testing is the process of putting demand on a

system or device and measuring its response.

o

Load testing is performed to determine a system’s

behavior under both normal and anticipated peak load conditions.

o It helps to identify the maximum

operating capacity of an application as well as any bottlenecks and determine

which element is causing degradation.

o

When the load placed on the system is raised

beyond normal usage patterns, in order to test the system's response at

unusually high or peak loads, it is known as stress testing.

o

The load is usually so great that error conditions

are the expected result, although no clear boundary exists when an activity

ceases to be a load test and becomes a stress test.

o There is

little agreement on what the specific goals of load testing are. o The

term is often used

synonymously with concurrency testing, software performance testing, reliability

testing, and volume testing.

Load testing is a type of non-functional testing.

Types Of Condition Monitoring

Systems

Condition

monitoring systems are of two types: periodic and permanent. In a periodic

monitoring system (also called an off-line condition monitoring

system), machinery vibration is measured (or recorded and later

analyzed) at selected time intervals in the field; then an analysis is made

either in the field or in the laboratory.

Advanced

analysis techniques usually are required for fault diagnosis and trend analysis. Intermittent monitoring provides

information at a very early stage about incipient

failure and usually is used where (1) very early warning of faults is required,

(2) advanced diagnostics are required, (3) measurements must be made at many

locations on a machine, and (4) machines are complex.

In a permanent

monitoring system (also called an on-line condition monitoring system),

machinery vibration is measured continuously at selected points of the machine

and is constantly compared with acceptable levels of vibration.The principal function

of a permanent condition monitoring system is to protect one or more machines

by providing a warning that the machine is operating improperly and/or to shut

the machine down when a preset safety limit is exceeded, thereby avoiding catastrophic

failure and destruction. The measurement system may be permanent (as in

parallel acquisition systems where one transducer and one measurement chain are

used for each measurement point), or it may be quasi-permanent (as in multiplexed

systems where one transducer is used for each measurement point but the rest of

the measurement chain is shared between a few points with a multiplexing interval

of a few seconds).

In a

permanent monitoring system, transducers are mounted permanently at each

selected measurement point. For this reason, such a system can be very costly, so

it is usually used only in critical applications where: (1) no personnel are

available to perform measurements (offshore, remote pumping stations, etc.),

(2) it is necessary to stop the machine before a breakdown occurs in order to

avoid a catastrophic accident, (3) an instantaneous fault may occur that

requires machine shutdown, and (4) the environment (explosive, toxic, or

high-temperature) does not permit the human involvement required by

intermittent measurements.

Before a

permanent monitoring system is selected, preliminary measurements should be

made periodically over a period of time to become acquainted with the vibration

characteristics of the machine. This procedure will make it possible to select

the most appropriate vibration measurement parameter, frequency range, and normal

alarm and trip levels.

Establishing A Condition

Monitoring Program

A

condition monitoring program may be established to check the satisfactory

operation of a single machine or, more usually, it is established to check the

operation of a number of machines,

perhaps all the machines in an entire plant. The following steps are usually

considered in the establishment of such a program, depending on the type of

machine and impact of failure of operation machines might have.

Step 1. Determine

the type of condition monitoring system, described

in the preceding section, that best meets the needs of the plant.

Step 2. Make a

list of all of the machines to be monitored

(see,

for example,Table 16.1), based on the importance of these machines in

the production line.

Step 3. Tabulate

the characteristics of the machines that are

important in conducting vibration analyses of the machines of step

2.These characteristics are associated with machine construction such as the

natural frequencies of shafts, casings, and pedestals, and operational and

defect responses.A tabulation of machine frequencies is important because fault

analysis is conducted (Table 16.2) by matching machine frequencies to measured

frequencies appearing in a spectrum. The following machine characteristics

provide the necessary information for fault analysis.

_ Shaft

rotational speeds, bearing defect frequencies, number of teeth in gears, number

of vanes and blades in pumps and fans, number of motor poles, and number of stator slots and rotor bars.

Vibratory

forces such as misalignment, mass unbalance, and reciprocating masses.

_

Vibration responses due to process changes, such as temperature and pressure.

_ Fault

responses associated with specific machine types, such as motors, pumps, and fans.

_

Sensitivity to instability in components, such as fluid film bearings and seals

due to wear and clearance.

_ Loads

or changes in operating conditions.

_ Effects

of mass unbalance, misalignment, distortion, and other malfunction/defect excitations

on vibration response.

Condition Monitoring Of Machinery

TABLE

16.1 Machinery Classification for Monitoring

Machinery classification Result of failure

Critical

Unexpected shutdown or failure causes significant production loss.

Interrupts

production Unexpected shutdown or failure causes minor interruptions in

production.

Causes

inconvenience Inconvenience in operation, but no interruption in production. Noncritical

Production is not affected by failure.

Step 4. Select

the most appropriate vibration measurement

parameter. When an accelerometer is employed as the

sensing device in a condition monitoring system, the resulting acceleration

signal can be electronically integrated to obtain velocity or displacement, so any one of these three

parameters may be used in measurements.

The

appropriate parameter may be selected by application of the following simple rule:

Use the parameter which provides the “flattest”

spectrum. The flattest spectrum requires

the least dynamic range from the instrumentation which follows the transducer.

For

example,Fig. 16.1 shows a velocity spectrum and a displacement spectrum obtained

under identical conditions. The dynamic range (i.e., the range from the highest

to the lowest signal level) required to measure the displacement spectrum is much larger than the range for the velocity spectrum; it may

even exceed the available dynamic range of the instrumentation.Therefore,

according to this rule, velocity measurements should be selected.

The flattest

spectrum rule applies only to the frequency range of interest. Therefore, the

parameter selection, to some extent, depends on the type of machine and the

type of faults considered.

Step 5. Select

one of the following vibration pickups

that will best meet the requirements of step 4.

Displacement

Transducer. A displacement transducer is a

transducer that converts an input mechanical displacement into an electrical

output that is proportional to the input displacement. Displacement transducer

of the eddy-current type (described in Chap. 12), which have noncontacting

probes, are commonly used to measure the relative motion between a shaft and

its bearings. This information can be related directly to physical values such

as mechanical clearance or oil-film thickness, e.g., it can give an indication

of incipient rubbing. Shaft vibration provides information about the current

condition of a machine and is principally used in permanent monitoring systems,

which immediately shut the machine down in the event of trouble. The use of

displacement transducers is essential in machinery having journal bearings.

However, proximity probe transducers (1) usually are difficult to calibrate

absolutely, (2) have limited dynamic range because of the influence of

electrical and mechanical runout on the shaft, and (3) have a limited

high-frequency range.

Accelerometers

and Velocity Pickup. Pickups of this type, described

in Chap.

12, are

usually lightweight and rugged. They are always used for detecting faults which occur at high

frequencies (say, above 1000 Hz), for example, to detect rolling element bearing

deterioration or gearbox wear. Acceleration measurements of bearing vibration

will provide very early warning of incipient faults in a machine.

Figure

16.1 Displacement and velocity spectra obtained under

identical conditions. The velocity spectrum requires a smaller dynamic range of

the equipment which follows the transducer.Therefore, it is preferable.

Step 6. Select

the measurement locations. When a

periodic (off-line) monitoring system is employed, the number of

points at which measurements are made is limited only by the requirement for

keeping measurement time to a minimum. As a general rule, bearing vibration

measurements are made in the radial direction on each accessible bearing, and

in the axial direction on thrust bearings. It is not usually necessary to

measure bearing vibration in both the horizontal and the vertical

direction, since both measurements give the same information regarding the

forces within the machine; this information is merely transmitted through two

different transmission paths. This applies for detecting developing

faults. It will later be seen, however, that in order subsequently to diagnose

the origin of the impending fault, measurements in both the horizontal and the

vertical direction may give valuable information.When measuring shaft vibrations

with permanently mounted proximity transducers, it is convenient to use two

probes on each bearing, located at 90 from each

other, thereby providing an indication of the orbit of the shaft within the

bearing.

Axial

displacement transducers, programmed to shut the machine down on preset levels,

are mounted where a thrust measurement will protect the machine rotating parts,

such as blades, from rubbing the stationary casing due to faultinduced axial

forces.

When a

permanent (on-line) monitoring system is employed using a seismic pickup, the

number of measurement points usually is minimized for reasons of economy. Selection must be made following a

study of the vibration spectra of different bearings in order to locate those

points where all significant components related to the different expected

faults are transmitted at measurable vibration levels if full spectrum

comparison is performed. If only broadband measurements are monitored, then a

further requirement is that all frequency components related to the expected

faults must be of approximately the same level within the selected frequency

range. Otherwise, measurements must be made in selected frequency bands.

Step 7. Select

the time interval between measurements.

The

selection of the time interval between measurements requires knowledge

of the specific machine. Some machines develop faults quickly, and others run

trouble-free for years. A compromise must be found between the safety of the

system and the time taken for measurements and analysis. Measurements should be

made frequently in the initial stages of a condition monitoring program to

ensure that the vibration levels measured are stable and that no fault is

already developing.When a significant change is detected, the time interval

between measurements should be reduced sufficiently so as not to risk a

breakdown before the next measurement.The trend curve will help in determining when

the next measurement should be performed.

Step 8. Establish

an optimum sequence of data acquisition.

The

sequence in which data acquired in a condition monitoring program must

be planned so that the data are acquired efficiently. For example, the data

collection may be planned on the basis of plant layout, on the type of data

required, or on the sequence of components in the machine train, from driver to

driven components.

Principles And Methods

As a

starting point for any discussion on condition monitoring it is useful to

define what is meant by the term, and to describe how it relates to other

techniques used in the operation and maintenance of machines, such as alarm and

shut down systems or methods for failure and problem investigation.

The

crudest method for operating machines is to run them until they fail, and then

to try and repair them in order to make them fit for further service. This

method of operation can be very expensive in terms of lost output and machine

destruction, and in addition can involve hazards to personnel. It is now well

recognised that, particularly in the case of large and expensive plant, it is

more economical and operationally satisfactory to carry out regular maintenance.

This involves the maintenance of the machine or its various components at

regular intervals, to reduce the likelihood of failure during a time when the

machine is required to be available for use.

The

problem in planning this type of maintenance lies in the choice of an

appropriate maintenance interval for the machine, because the actual running time

before maintenance is really needed is not constant, but varies from one

occasion to another, due to differences in the operation of the machine in the

behaviour of its components.

Fig. 1

shows how the running time to failure of a typical machine would be likely to

vary if no preventive maintenance were carried out. The vertical line in this

diagram represents the safe time interval between preventive maintenance work

which could catch all the failures before they occurred. If this safe overhaul

interval is chosen, however, there will be many occasions when the machinery

will be overhauled long before it is really necessary,such as in those cases at

the right hand side of the curve where it could have run on for much longer

without failing.

This

situation wastes production time, and by increasing the frequency of

maintenance operations increases the incidence of human errors on reassembly of

the machine.

A more

satisfactory compromise in terms of maintenance strategy is to carry out

preventive maintenance at what may be irregular intervals, but to determine

these intervals by the actual condition of the machine at the time. For such

condition-based maintenance to be possible,it is essential to have knowledge of

the machine condition and its rate of change with time. The main function of

condition monitoring is to provide this knowledge.

There are two main methods used

for condition monitoring, and these are trend monitoring and condition checking.

Trend monitoring is the continuous or regular measurement and interpretation of

data, collected during machine operation, to indicate variations in the

condition of the machine or its components, in the interests of safe and

economical operation.

This

involves the selection of some suitable and measurable indication of machine or

component deterioration, such as one of those listed in Fig.2, and the study of

the trend in this measurement with running time to indicate when deterioration

is exceeding a critical rate.

The

principle involved is illustrated in Fig.3, which shows the way in which such

trend monitoring can give a lead time before the deterioration reaches a level

at which the machine would have to be shut down.

This lead

time is one of the main advantages of using trend monitoring rather than simple

alarms or automatic shut down devices.

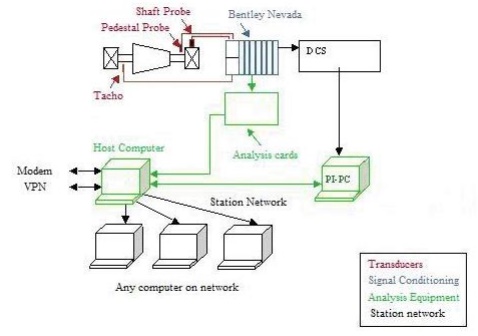

Vibration

Monitoring System (VMS) Specification

To identify potential turbine generator fault mechanisms and so

enable informed operational decisions, sophisticated vibration data analysis is

required. To do this a modern dedicated vibration monitoring system (VMS) is

required. Vibration Diagnostics can provide vibration specification and

commissioning services.

Related Topics