Chapter: Mechanical : Maintenance Engineering : Condition Monitoring

Repair Methods For Basic Machine Elements

REPAIR METHODS FOR BASIC MACHINE ELEMENTS

Repair Methods For Beds

MANY READERS must be in possession

of lathes and other machinery that have slide wear con-centrated in sections of

most use. 1 expect that some have heard of, if not come in contact with, the

old craftsman held in awe because his mach-ine is in such a bad condition that

he is the only one able to produce good work from it. How much better he could

perform on a good machine where full concentration could be given to the w o r

k p i e c e r a t h e r t h a n t h e e c c e n t r i c i t i e s a n d

shortcomings of his machine tool.

An accurate machine is a joy to use. but wear creeps in

insidiously, one foun impos day it is gibs to ful d s- ible to adjust trave and

the give l l yet b tigh enoug accurat wor in sectio e t h for e k the n mos

use. this arise it of t When situation s does not necessarily mean an expensive

regrind for your lathe bed for example, my aim is to show how small machine

tool slides may be restored by the amateur with a minimum of equipment. In this

age of enormous labour costs few reasonably priced machines have hand-finished

slides, so machines may profit from owne of rs new a little of work shall attempt

to describe. the I Rather than describe the overhaul of a par-ticular make and

type of machine 1 shall give a procedure for a 3-1/2 in. lathe, I am sure

readers will be able to apply the principles and methods involved to their own

make and size of lathe, also millers, shapers etc.

Before stripping, overhaul the headstock man-drel and

bearings. I do not intend to enlarge on this, volumes have been written on the

subject, adjustment is usually built in anyway. Good bear- ings are essential

for up the lat letting is still slides er

an the lathe new hav d intact

if bearings e to be machined. right down th

Strip the lathe bed,

now check the to e

mounting onto stan the bed is

not bench or d that twisted by dow the holding n bolts, this can be checked

with a sensitive spirit level across headstock seating and unworn sec-tions of

bed, readings should be exactly the

same, if not shim adjust jacking bolt or the s to correct. Much care be with more must

taken a bed mounted on feet at each end

than the cantilever type.

Clean the bed thoroughly with carbon tet. or similar solvent

and take a good look at it in c o n j u n c t i o n w i t h t h e s a d d l e ,

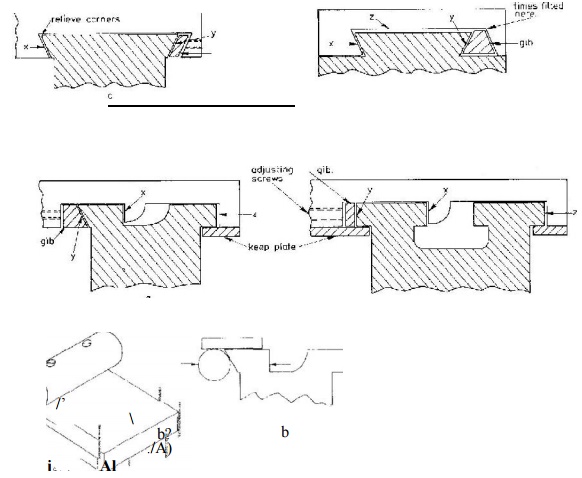

h e a d s t o c k , tail-stock and sketches Fig. 1, identify the main guide faces,

these will always be opposite the gib faces.

Now to check the wear present, I doubt if many readers have a

fishback surface plate as

long as the bed, but a 24 in.

straight-edge can, with care, be used equally well. The thick type of

straight-edge as used in combination sets is c e r t a i n l y t h e b e s t a

n d e a s i e s t t o u s e . T h e s e straight-edges can be obtained plain without

graduations at a considerable saving In cost.

Try along the top flats of the

bed with the straight-edge, if the headstock seating is on the same level as

the bed, bridge the gap from un-worn seating to bed as far back as possible and

try to insert a .0015 in. feeler gauge in worn section; unless

wear is excessive you will prob-ably find that

It won’t go. Wear will have to be

detected by holding the straight-edge firmly down on the bed

carefully keeping it vertical and flex-ing it sideways, a little practice and

you will be able to feel where the bed is hollow or worn.

Check the bed all over including guide edges in this manner,

you will probably be comforted to find that very little wear is causing all

that trouble. A check on the actual amount of wear present can be taken by

using micrometers, vernier or ordinary calipers over and between all bed

surfaces. To measure over vee slides a jig or jigs must be made as shown in

Fig. 2. Screw a 1-1/2in. length of ground stock to a piece of 1-1/2 in. x 1/4

in. flat with one face trued flat.

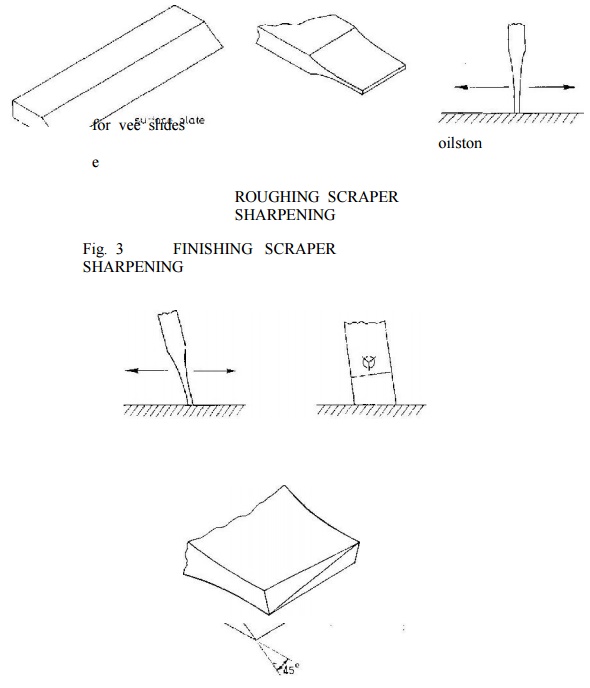

Before scraping the bed a good

surface plate at least 6 in. x 6 in. will be necessary and also an off

standard one about 2 in. x 1 in.

x 8 in. with one edge machined and scraped flat at about 45 degrees. a piece of

old cast iron strip from a large machine is excellent, see Fig. 3.

Cast iron tends to form a thin

but very hard skin, so a few words on scrapers and the method of attacking the

surface are in order. I have not yet found a commercial scraper that is hard

enough for use on machine slides, 1 have found the best is a good quality

parallel flat file thinned by grinding see Fig. 3 and the end hardened right

out by quenching in water; for the work in hand 3/4 in. wide is about right.

Two different methods of sharpening are used, one for roughing

and one finishing. The rough-ing scraper is flat and straight ended, not

curved, as the book says and the finishing scraper is

sharpened as Fig. 3. This scraper is used to remove the high

spots and is worked with a sort of forward-sideways-rocking motion, like

digging high out. sorry, but the spot I am this is the descripti I am able to

give, best on those that are able to mottle will understand what I mean and

also the difficulty of describing it, how-ever do not despair if you are not

able to mottle, a very attractive frosted effect may be obtained quite easily.

Start scraping down the top of the bed with the roughing

scraper. Work at about 45 degrees across the bed, use long even strokes and put

som pressur on, try remov met evenly e e to e al . difficul encounter breaki

the skin If ty 6 is ed ng use fin fla fil press agai at a e in. t e ed firmly,

n about 45 degrees across the bed and worked slowly and evenly. This will score

the surface to give the scraper a bite. With the skin removed use level,

straight-edge and feelers to take the high areas down evenly to the lowest

point of wear. The scraper should be sharpened frequently on a India use

anything medium stone, do not coarser as it will cause scraper score the

bed.

the to Each pass along the bed should be at 90 degrees to the

previous one.

When you are satisfied the bed is dead flat t o t h e s t r a i g h t - e d g e s m e a r t h e l a r g e s u r f a c e plate with engineers’ marking blue and slide it up and down the bed a few times, the high spots revealed will probably be few and far between, but if the preceding work has been correctly carried out no perceptible rock should be felt in the plate. Still using the roughing scraper, take the high spots off and repeat a few times until a reasonable contact is shown all over the bed. By now smal! bright spots surrounded by blue should begin to appear, using the finishing scraper take these off. A word of caution. large areas of heavy blue do not mean a good bearing, it means too much blue on the plate, 1 repeat, the very high spots will show bright surrounded by blue. If you pick the high spots off with a short forward and sideways motion working at 45 degrees across the bed and the next time the plate is used, at 45 degrees the other way the high spots appea in more dense clusters and will r a very nic froste effect will take form on the e d bed. It is now up to the individual how much time, patience and dexterity he puts in to obtain a bearing surface, the more and closer the high spots, the greater bearing and flatter surface, but whenever the work is stopped the bearing should be even all over the bed. All the low areas sur-rounded the high spots are “oil wells” which will help to retain lubrication on the surface.

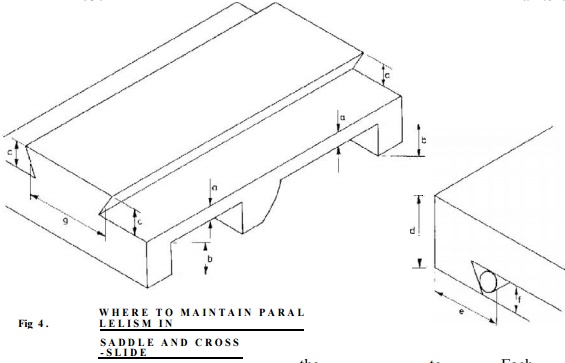

Locate the main guide face and carry out the same procedure on

it, if this face serves as the headsto location work this as well to ck on

obtain a flat face through. The straight right tailstock is probably guided by

the same face as the saddle but if not, this is the next for attention,

measurements must be taken from the completed face to ensure parallelism. The

secondary or gib

Related Topics