Chapter: Mechanical : Maintenance Engineering : Condition Monitoring

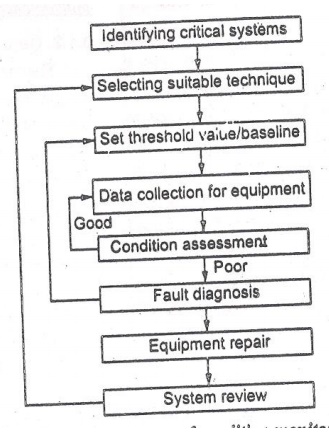

Process involved in condition monitoring

Process involved in condition

monitoring

Conditions monitoring is one of

the maintenance methods which are used to assess the health and condition of

equipments machines, systems or process by absorbing checking, measuring and

monitoring several parameters. This technique is also called as equipment

health monitoring.

1.

Identifying critical systems

2.

Selecting suitable techniques for condition

monitoring

3.

Setting baselines

4.

Data collection

5.

Data assessment

6.

Fault diagnosis and repair

7.

System review

advantages

and disadvantages and disadvantages of condition monitoring. Advantages

•

Improved availability of equipment

•

Minimized breakdown cost

•

Improved reliability Disadvantages

•

Gives only marginal benefits

•

Increased running cost

Sometimes difficult to organize

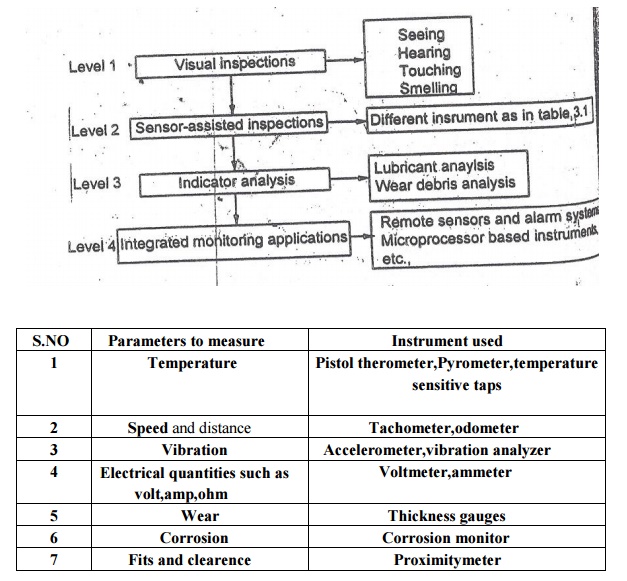

various levels of condition

monitoring

Visual monitoring:

Machine components are visually inspected to

determine their condition a.Sight Leaks

Smoke or casing colour change, indicating

overheating. b.Smell Overheating

Leaks

c.Hearing Abnormal

noise, indicating some malfunction.

d.Feel Abnormal vibration, indicating

some malfunction, high casing temperatures, indicating overheating

Wear debris and contaminant

monitoring.

1.

Direct detection of the debris in the oil in the

machine optical methods.

2.

Electrically conducting filters.

3.

Inductive and capacitative methods.

4.

Collection of the debris in the machine for

regular examination.

5.

Existing filtration system.

6.

Special filters.

7.

Magnetic plugs.

8.

Regular sampling of the lubricant for an analysis

of its contents.

9.

Elemental (spectrometric) analysis.

10.

Magnetic particle separation.

11.

Automatic particle counting.

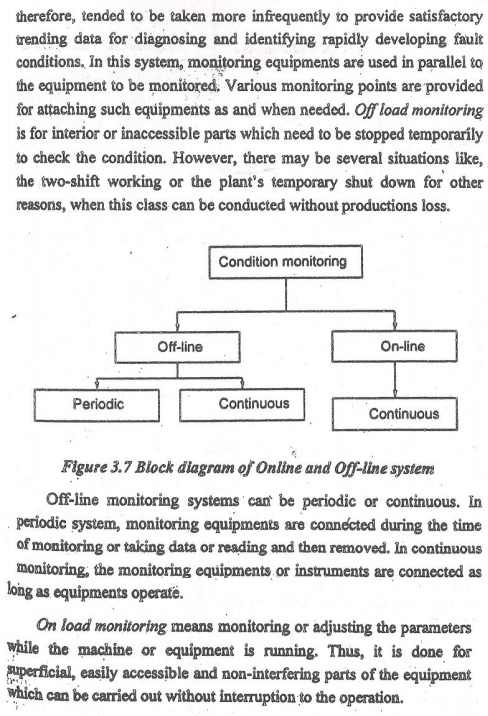

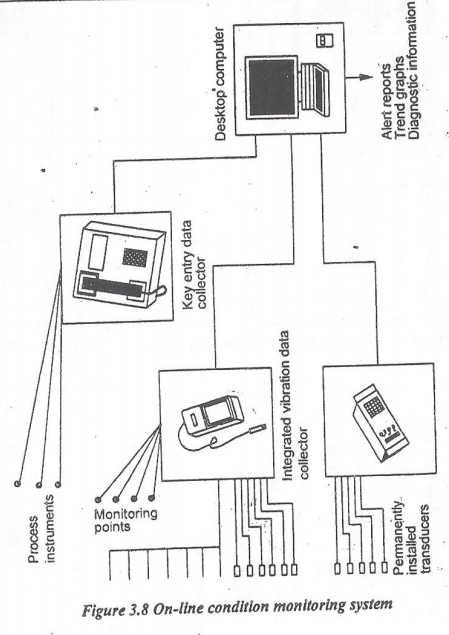

on-load and off-load testing used

in condition monitoring

Condition monitoring can be done

in two methods viz,off-line or on- line.In off-line condition monitoring,the

machine is withdrawn from service and disconnected from its normal supply. Measurements

of system, monitoring equipment are built in or

installed in series with the running

Related Topics