Chapter: Civil : Soil Mechanics : Soil Classification And Compaction

Compaction

Compaction

Compaction

In construction of highway

embankments, earth dams and many other engineering structures, loose soils must

be compacted to improve their strength by increasing their unit weight;

Compaction - Densification of soil by removing air voids using mechanical equipment;

the degree of compaction is measured in terms of its dry unit weight.

1 Objectives for Compaction

Ø Increasing

the bearing capacity of foundations;

Ø Decreasing

the undesirable settlement of structures;

Ø Control

undesirable volume changes;

Ø Reduction

in hydraulic conductivity;

Ø Increasing

the stability of slopes.

In general, soil densification includes compaction

and consolidation.

Compaction is one

kind of densification that is realized by rearrangement of soil particles without

outflow of water. It is realized by application of mechanic energy. It does not

involve fluid flow, but with moisture changing altering.

Consolidation

is

another kind of densification with fluid flow away. Consolidation is primarily

for clayey soils. Water is squeezed out from its pores under load.

CONSOLIDATION

It is a

gradual process of reduction of Volume under sustained, static loading.

It causes

a reduction in volume of a saturated soil due to squeezing out of water from

the soil.

Is a

process which in nature when saturated soil deposits are subjected to static

loads caused by the weight of the building

COMPACTION

It is a

rapid of reduction of volume mechanical mean such as rolling , tamping ,

vibration.

In

compaction, the volume of partially saturated soil decreases of air the voids

at the unaltered water content

Is an

artificial process which is done to increase the density of the soil to improve

its properties before it is put to any use.

2 Compaction Effect

There are 4 control factors affecting the extent of

compaction:

Ø Compaction

effort;

Ø Soil type

and gradation;

Ø Moisture

content; annd

Ø Dry unit

weight (dryy density).

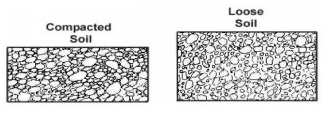

3 Effect of Water on Compaction

In soils, compaction is a funnction of water content

Water added to the soil duri ng compaction acts as a softening

agent on t he soil particles

Ø Consider

0% moistu re - Only compact so much

Ø Add a

little water - compacts better

Ø A little

more water - a little better compaction

Ø Even more

water - Soil

begins to flow

What is better compactionn?

The dry unit weight (?d) inccreases as the moisture

content increases to a point

Beyond a certain moisture

content, any increase in moisture content ten ds to reduce the dry unit weight

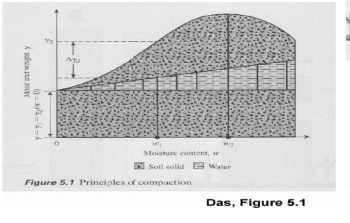

4 Standard Proctor C ompaction Test

The

standard was originall y developed to simulate field compaction in the lab

Purpose:

Find the optimum moisture content

at which the maximum dry unit weig ht is attained ASTM D 698

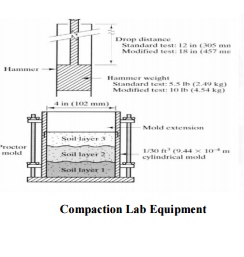

Equipments;

Standard Proctor; 1/30 ft3

mold 5.5 lb hammer; 12' drop

3 layers of soil; 25 blows / l ayer

Compaction Effort is calc ulated with the

following parameters

Mold volume = 1/30 cubic foot Compact in 3 layers

25blows/layer

5.5 lb hammer 12"

drop

Procedure

1. Obtain 10

lbs of soil pass ing No. 4 sieve

2.

Record the weight of the Proctor mold without the

base and the (c ollar) extension, the volume of which is 1/30 ft3.

3. Assemble

the compactio n apparatus.

4.

Place the soil in the mold in 3 layers and compact

using 25 well dist ributed blows of the Proctor hammer.

5. Detach

the collar without disturbing the soil inside the mold

6. Remove

the base and determine the weight of the mold and compacte d soil.

7.

Remove the compacted soil from the mold and take a

sample (20-30 grams) of soil and find the moisture content

Place the

remainder of th e molded soil into the pan, break it down, and thoroughly remix

it with the other soil, plus 100 additional grams of water.

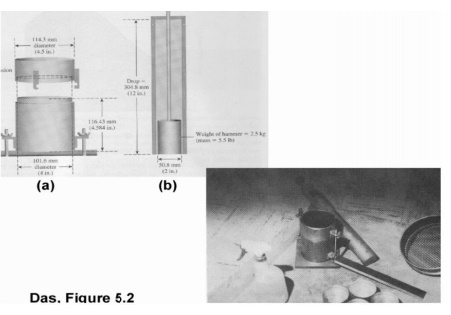

Zero-air-void unit weight:

At

certain water content, w hat is the unit weight to let no air in the voids

It is clear that in the above

equation, specific gravity of the solid and thewater density are constant, the

zero-air-void density is inversely proportional to water content w. For a given

soil and water content the best possible compaction is represented by the

zero-air-voids curve. The actual compaction curve will always be below. For dry

soils the unit weight increases as water is added to the soil because the water

lubricates t he particles making compaction easier. As moree water is added and

the water content is larg er than the optimum value, the void spaces be come

filled with water so further compac tion is not possible because water is a

kind like incompressible fluid. This is illustrated by t he shape of the

zero-air-voids curve which decre ases as water content increases.

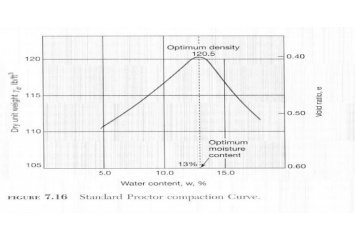

Compaction Curve

Compaction curve

plotted ?d vs. w.The peak of the

curve is the Maxim um Compaction (?d max) at Optimum Moisture Content

(wopt )

Results

Plot of dry unit weight vs m oisture content

Find

?d (max) and w and Plot

Zero-Air-Void unit weight (only S=100% )

5 Effect of Compacti on Energy

With the development of heavy

rollers and their uses in field compaction, the Standard Proctor Test was

modified t o better represent field compaction

As the compaction effort increases,

The maximum dry unit w eight of

compaction increase; the optimum moisture content decreases to some extend

Compaction energy per unit volume.

6 Compaction adopte d in the field

i) Tampers.

A hand operated tamper consists

of block iron, about 3 to 5 Kg mass, a ttached to a wooden rod. The tamper is

lifted for about 0.30m and dropped on the soil to be compressed. Mechanical

Tampers operatted by compressed air or gasoline power.

ii) Rollers

a) smooth - wheel

rollers

b) pneumatic

- tyred

rollers

c) Sheep-

foot rollers.

a) Smooth - wheel

rollers

Smooth - wheel

rollers ar e useful finishing operations after compaction of fillers and for

compacting granular base causes of highways.

b) Pnumatic - tyred

roller s

Pneumatic - tyred

rollers u se compressed air to develop the required in flation pressure.The

roller compactive the soil primarily by kneading action. These rolle srs are

effecting for compacting cohesive as we ll as cohesion less soils.

c) Sheep - foot

rollers

The sheep - foot roller con sists of a hollow drum with a large number of small projections (known as feet) on its surf ace. The drums are mounted on a steel frame. The drum can fill with water or ballast incre ases the mass. The contact pressure is gener ally between 700 to 4200 KN/m2.

Related Topics