Chapter: Special Electrical Machines : Permanent Magnet Brushless D.C. Motors

Commutation in Motors With 120┬░ and 180┬░ Magnet Arc

COMMUTATION IN MOTORS WITH 120┬░

AND 180┬░ MAGNET ARC

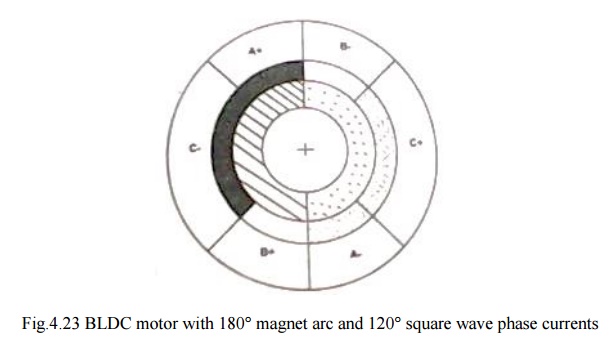

BLPM dc

motor with 180┬░ magnet arcs and 120┬░ square wave phase currents arc shown in

fig. 4.23 and 4.24.

In Fig.

4.26 the rotor magnet poles are shaded to distinguish north and south. The

phase belts are shaded us complete 60┬░ sector of the stator bore. There are two

slots in each of these phase belts. The current in these two slots are identical

and conductors in them are in series

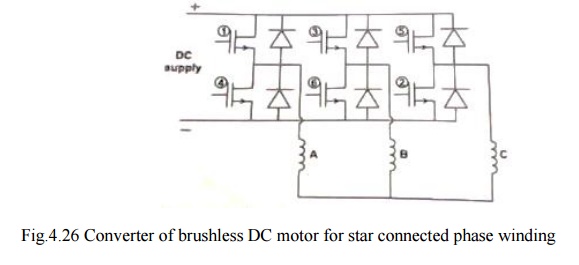

Between the rotor ring and the stationary belt ring in fig. 4.26 there is a third ring called the ŌĆ¢mmf ringŌĆ¢. This represents the mmf distribution of the stator currents at a particular instant.

v At the

instant shown wt=0, phase A is conducting positive current and phase C is

conducting negative current. The resulting mmf distribution has the same shading

as the N and S rotor poles to indicate the generation of torque,

v Where the

mmf distribution has like shasing, positive torque is produced. Where mmf and

flux shading are unlike, negative torque is produced. Where one is zero, no

torque is zero, no torque is produced. The total torque is the integral of the

contributions from around the entire air gap periphery.

The rotor is rotating in the clockwise direction.

After 60┬║ of rotation, the rotor poles start to ŌĆŚuncoverŌĆś the C phase belts and

the torque contribution of phase C starts to decrease linearly.

During this period, the magnet poles, have been 'coveringŌĆś the B phase belts. Now if the negative current is commutated from C

to B exactly at then point 60┬║, then the torque will be unaffected and will

continue constant for a further 60┬║. After 120┬║, positive current must be

commutated from A to C.

Commutation

tables for three-phase brushless dc motors.

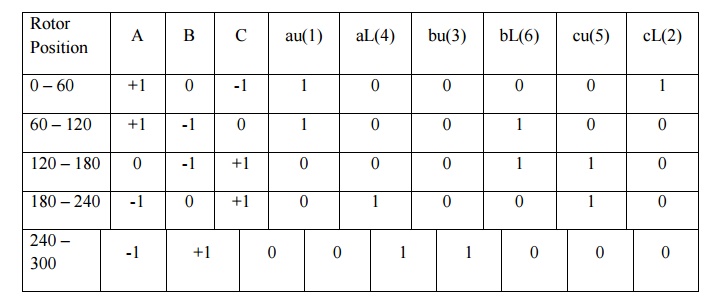

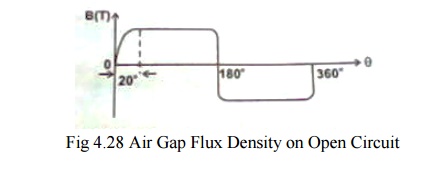

TABLE 4.1 180┬║ Magnet-Star

Winding. 120┬║ Square wave phase Currents

v The

production of smooth, ripple free torque depends on the fact the magnet pole

arc exceeds the mmf arc by 60┬║.

v Here only

2/3 of the magnet and 2/3 of the stator conductors are active at any instant

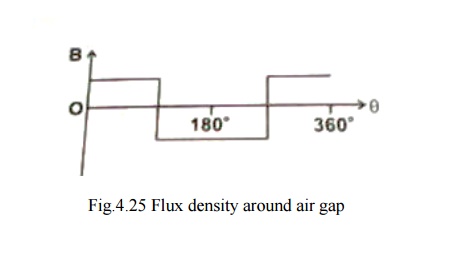

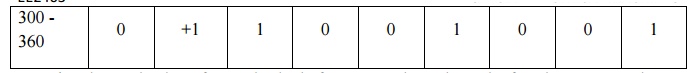

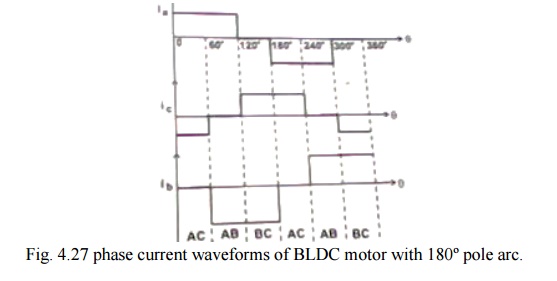

In a

practical motor the magnet flux-density distribution cannot be perfectly

rectangular as shown in fig.4.27. for a highly coercive magnets and full 180┬║

magnet arcs there is a transition section of the order of 10-20┬║ in width. This

is due to fringing effect. Likewise on the stator side, the mmf distribution is

not rectangular but have a stepped wave form as shown in fig.4.28 that reflects

the slotting.

To some

extent these effects cancel each other so that s that satisfactory results are

obtained with a magnet arc as short as 150┬║, and two slots per pole per phase.

But there

is always dip in the torque in the neighborhood of the commutation angles. This

torque dip occurs every 60┬║ elec degrees, giving rise to a torque ripple

component with a fundamental frequency equal to 6P times the rotation frequency

where P is the number of pole pairs. The magnitude and width of the torque dip

depends on the time taken to commutate the phase current.

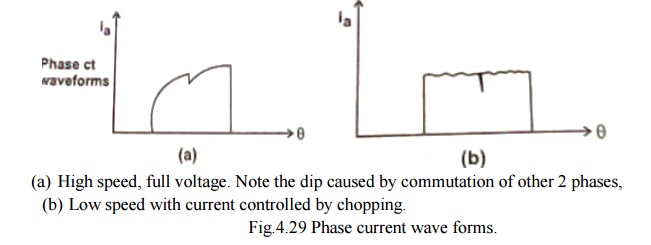

Phase

current waveforms corresponding to high speed and low speed operations are as

shown in fig. 4.29 (a & b)

(a) High

speed, full voltage. Note the dip caused by commutation of other 2 phases,

(b) Low speed

with current controlled by chopping.

Fig.4.29

Phase current wave forms.

v The back

emf is of equal value in the incoming phase and is in such a direction as to

oppose the current build up.

v While the

flux distribution of the magnet rotates in a continuous fashion, the mmf

distribution of the stator remains stationary for 60┬║ and then jumps to a

position 60┬║ ahead.

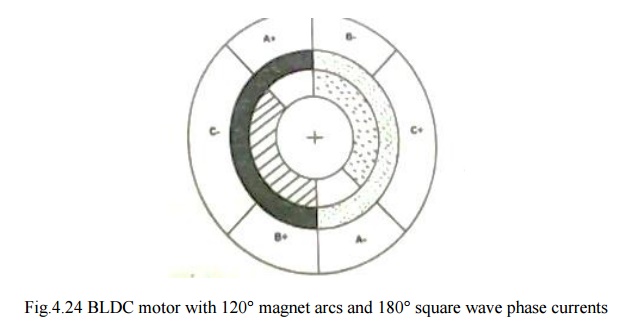

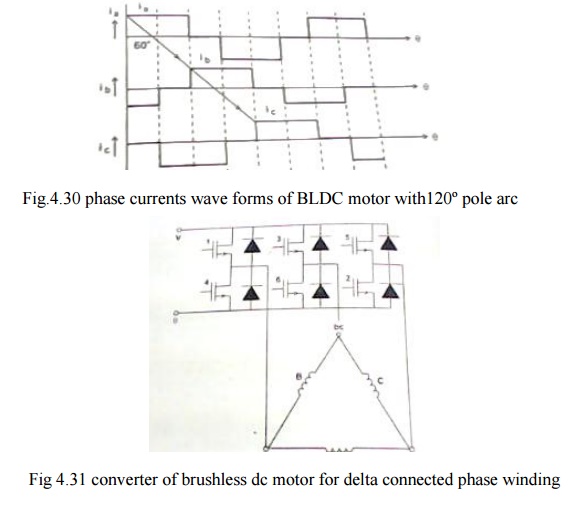

Similar

analysis is made with a motor having 120 ┬║ pole arc magnets with delta

connected armature winding.

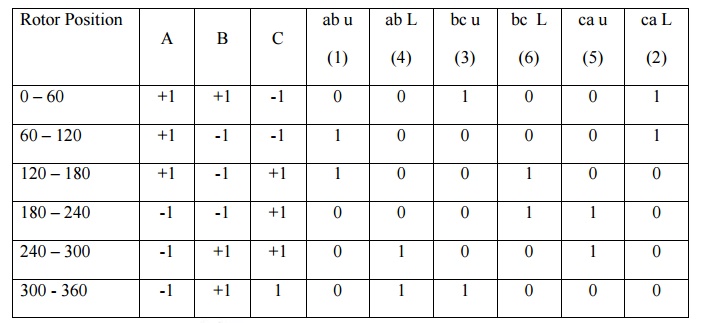

Table 4.2 120┬║ Magnet Delta

Winding, 180┬║ Square Wave Phase Currents.

v C phase

belt remains covered by the magnet poles. While the coverage of A phase belt

increases thereby decreasing that of B phase belt.

v Since all

the conductors are varying same current the increasing torque contribution of

phase A is balancing by the decreasing contribution of phase B. Therefore, the

total torque remains constant.

v Similarly

there is a linear increase in the back emf of A and equal and oppoaite decrease

in the back emf in phase B, Therefore the back emf at the terminals remains

constant.

v Line

current divides equally between two paths One-phase C Second-phase A & B

series.

This

balance is not perfect in practice because of the resistance and inductance of

the windings.But the current balance should be maintained, otherwise

circulating current may produce excessive torque ripple and additional losses.

When

compared with 180┬░ pole arc machine.

v For the

same ampere-conductors per slot and for the same peak flux density, the 120┬░

pole arc machine has 1.5 times copper losses, but produces the same torque.

v Also the

ampere-conductors per slot would have to be reduced because the duty cycle is

1.0 instead of 2/3.

Merits

v For the

same magnet flux density the total flux is only 2/3 of that of 180┬░ pole arc

motor, so that only 2/3 of the stator yoke thickness is required. If the stator

outside diameter is kept the same, the slots can be made deeper so that the

loss of ampere conductors can be at least partially covered .consequently the

efficiency of the motor may not be very much less than that of 180┬░ pole arc

machine.

v In this

machine also, the effects of fringing flux, slotting and communication overlap

combine to produce torque ripple.

v Only emf

and torque are discussed. The concept of hanging flux-linkage and energy

balance can also be used to analyze the operation.

Related Topics