Chapter: 11th Food Service Management : Chapter 4 : Food Service Equipment

Care, Maintenance and Sanitation of Equipment

Care,

Maintenance and Sanitation of Equipment

All equipment large or small,

heavy or light requires care in handling to extend its life to maximum and to

minimize depreciation and maintain in a reason-ably attractive and efficient

condition while in use.

General Care of Equipment is Given Below:

·

Keep all

equipment clean

·

Wash

removable parts of equipment with suitable detergent and hot water after each

use. After washing, wipe equipment completely dry before replacing.

·

Check

that all pieces are in working order.

·

Close

supervision at work is necessary to ensure careful handling.

·

Repairs

must be attended without delay to prevent damage.

·

A weekly, fortnightly or monthly pro-gramme for

oiling on servicing the equipment to maintain movable parts or machinery in

order is important.

·

All the electrical inputs to the equip-ment should

be checked periodically to ensure the proper electrical load is available for

efficient functioning.

·

Insulations, plumbing and other connec tions need

periodic check to keep equip-ment running at optimum efficiency.

·

Make full use of warranty periods to help and train

organisation staff to learn regular maintenance procedures from the

manufacturers and engineers.

·

Assign

the care of each machine to one responsible person. Money, time and effort

spent on care helps to maintain equipment in continuous working order.

1. Equipment Cleaning

·

All

equipment coming in contact with food should be kept clean.

·

They

should be scrubbed, cleaned with detergent and rinsed with potable water.

·

Dipped in

hot water at least for 30 sec-onds and then dry.

·

Parts of

blender and mixers should be inspected after cleaning.

·

Use

separate cutting board for different foods (for vegetarian and non vegetarian)

·

Prepare

raw food in separate area.

·

Clean and

sanitize equipment, utensils, work space after preparing each food.

·

Use

specific containers for various food products

·

Use clean

cloth or paper towel for wip-ing spills

2. Preventive Measures to Exclude Entry of Insects

Filling cracks and fissures in the walls and flooring

·

Covering drain holes, with wire gauze

·

Spraying or dusting with pesticide

·

Fumigation

in large godowns.

3. Cleaning Tools

Sanitation is a quality aspect that requires alert vigilance. It limits

possible exposure to contamination.

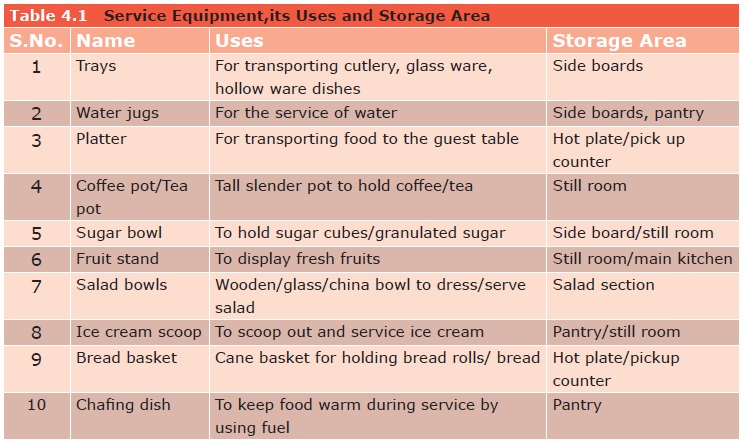

Food service equipment of var-ious qualities are available to meet the

requirements of different styles of cater-ing operations. The menu forms the

basis for identifying the requirement of service equipment. Though different

types of service equipment may be procured for dishes and drinks offered for

sale, using multipurpose equipment not only saves money but also reduces

storage space and maintenance cost. Purchasing of equip-ment is a managerial

activity which calls for careful and wise decisions since it involves major

capital investment. Every piece of equipment chosen must be justi-fied and it should

not remain idle.

![]()

Equipment must be maintained and

handled carefully since poor han-dling leads to additional costs. Adequate

training should be imparted to employee for proper handling of equipment. Too

much of stock occupies more storage and involves additional cost and too less

of it affect the operational efficiency. Hence it is important to strike a

balance between these two and have just the right amount of service equipment.

All equipment must be left clean

after use. When sanitation of equipment is not effective in food production and

while serving, food poisoning and food infections might occur and food service

will lose its customers. Hence cleaning and sanitation operation should be

verified on regular basis and it forms an important step in food service.

Related Topics