Chapter: Modern Analytical Chemistry: Basic Tools of Analytical Chemistry

Basic Equipment and Instrumentation of Analytical Chemistry

Basic Equipment and

Instrumentation

Measurements are made

using appropriate equipment or instruments. The

array of equipment and

instrumentation used in analytical chemistry is impressive, ranging from the simple and

inexpensive, to the

complex and costly.

With two exceptions, we will postpone the discussion of equipment and instrumentation where they are used. The instrumentation used to measure

mass and much of

the equipment used to measure

volume are important

to all analytical techniques

and are therefore discussed in this section.

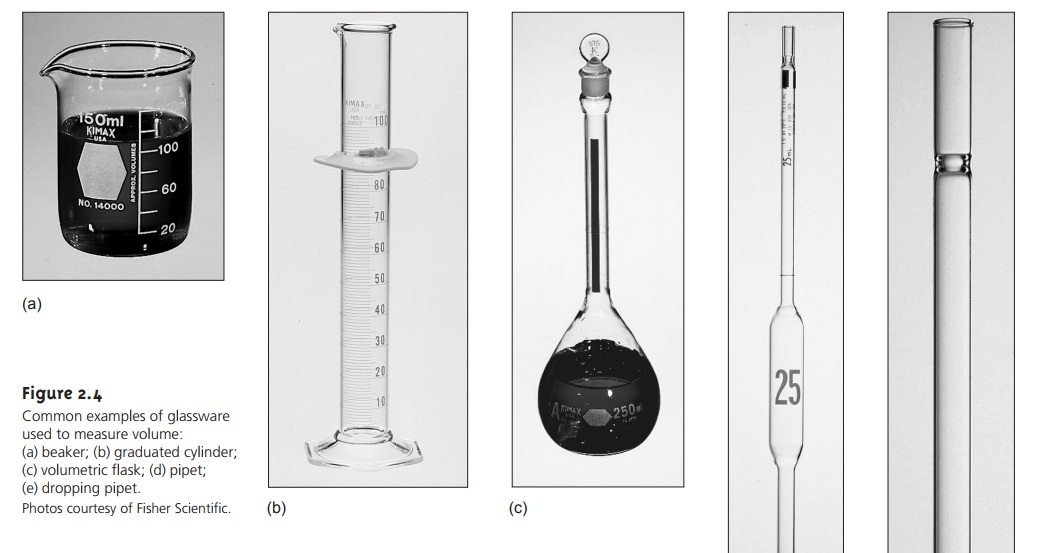

Instrumentation for Measuring Mass

An object’s mass is measured

using a balance. The

most common type of balance is an electronic balance

in which the balance pan is placed over an electromagnet

(Figure 2.2). The

sample to be weighed is placed on the sample

pan, displacing the pan

downward by a force equal

to the product of the sample’s mass and the acceler-

ation due to gravity. The balance detects

this downward movement

and generates a counterbalancing force using an electromagnet. The

current needed to produce this force is proportional to the object’s

mass. A typical

electronic balance has a capacity of 100–200 g and

can measure mass

to the nearest

±0.01 to ±1 mg.

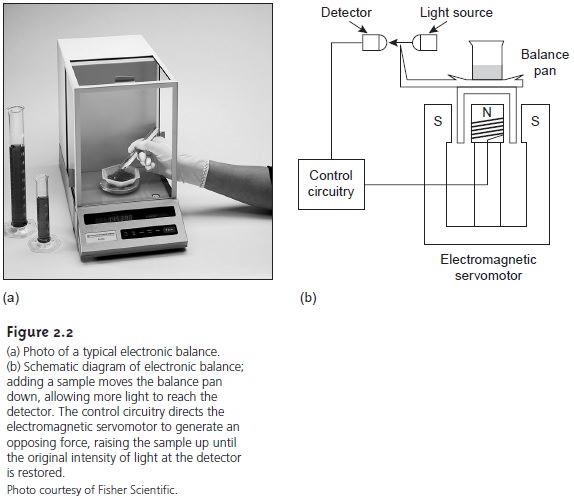

Another type of balance is the single-pan, unequal arm balance (Figure 2.3). In this mechanical balance the balance pan and a set of removable standard weights on one side of a beam are balanced against a fixed counterweight on the beam’s other side. The beam itself is balanced on a fulcrum consisting of a sharp knife edge. Adding a sample to the balance pan tilts the beam away from its balance point. Selected stan- dard weights are then removed until the beam is brought back into balance. The com- bined mass of the removed weights equals the sample’s mass. The capacities and mea- surement limits of these balances are comparable to an electronic balance.

The mass of a sample

is determined by difference. If the material

being weighed is not moisture-sensitive, a clean and dry container is placed on the balance.

The mass of this container is called the tare. Most balances allow

the tare to be automat- ically adjusted to read a mass of zero.

The sample is then transferred to the con- tainer, the new mass

is measured and

the sample’s mass

determined by subtracting the tare. Samples that absorb moisture

from the air are weighed

differently. The sample is placed in a covered

weighing bottle and their combined

mass is deter- mined. A portion of the sample

is removed, and

the weighing bottle

and remaining sample are reweighed. The difference between

the two masses

gives the mass of the transferred sample.

Several important precautions help to minimize

errors in measuring an object’s mass. Balances

should be placed

on heavy surfaces

to minimize the effect of vibra-

tions in the surrounding environment and should be maintained in a level

position. Analytical balances are sensitive enough

that they can measure the mass of a finger- print. For this reason,

materials placed on a balance

should normally be handled

using tongs or laboratory tissues.

Volatile liquid samples

should be weighed

in a covered container to avoid the

loss of sample

by evaporation. Air

currents can sig- nificantly affect a sample’s mass. To avoid

air currents, the

balance’s glass doors should be closed, or the balance’s wind shield should

be in place. A sample

that is cooler or warmer than the surrounding air will create

convective air currents

that adversely affect the

measurement of its

mass. Finally, samples

dried in an oven should be stored

in a desiccator to prevent

them from reabsorbing moisture from the atmosphere.

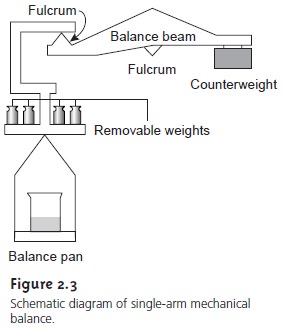

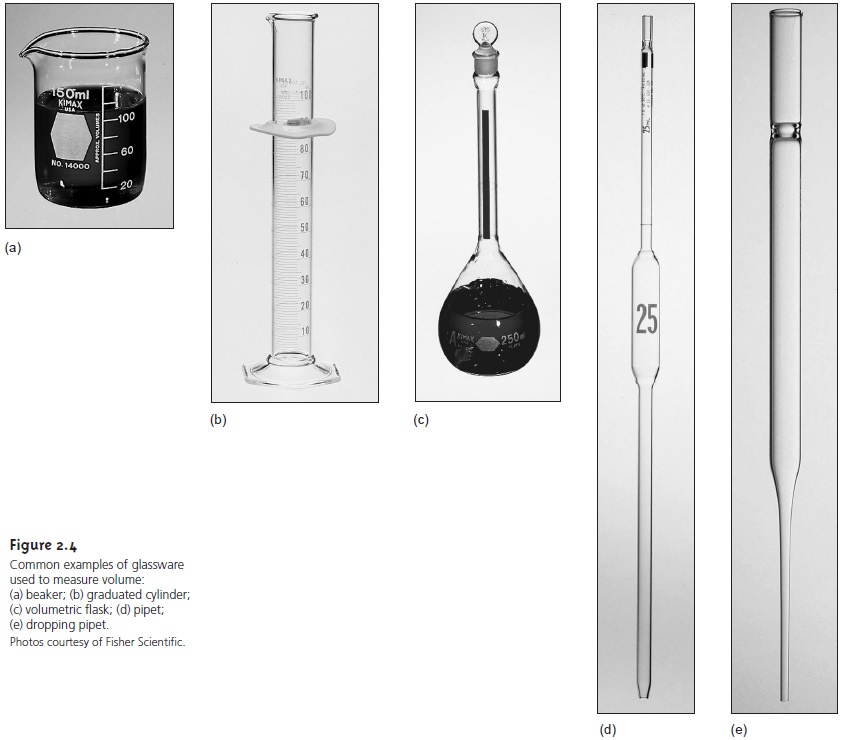

Equipment for Measuring Volume

Analytical chemists use

a variety of glassware to measure volume,

several examples of which

are shown in Figure 2.4. The type of glassware used depends on how exact the volume needs to be. Beakers,

dropping pipets, and graduated cylinders are used to measure

volumes approximately, typically with errors of several percent.

Pipets and volumetric flasks provide a more accurate means for measuring vol- ume. When filled to its calibration mark, a volumetric flask is designed to contain a specified volume of solution at a stated temperature, usually 20 °C.

The actual volume contained by the volumetric flask is usually

within 0.03–0.2% of the stated value. Volumetric flasks containing less than 100 mL generally measure volumes to the

hundredth of a milliliter, whereas

larger volumetric flasks

measure volumes to the

tenth of a milliliter. For example, a 10-mL volumetric flask contains 10.00

mL, but a 250-mL

volumetric flask holds

250.0 mL (this

is important when

keeping track of significant figures).

Because a volumetric flask contains a solution, it is useful in preparing

solu- tions with exact

concentrations. The reagent

is transferred to the volumetric flask, and enough solvent

is added to dissolve the reagent. After the reagent

is dissolved, additional solvent

is added in several portions, mixing the solution

after each addi- tion. The final adjustment of volume to the flask’s

calibration mark is made using a

dropping pipet. To complete the mixing process,

the volumetric flask

should be in- verted at least ten times.

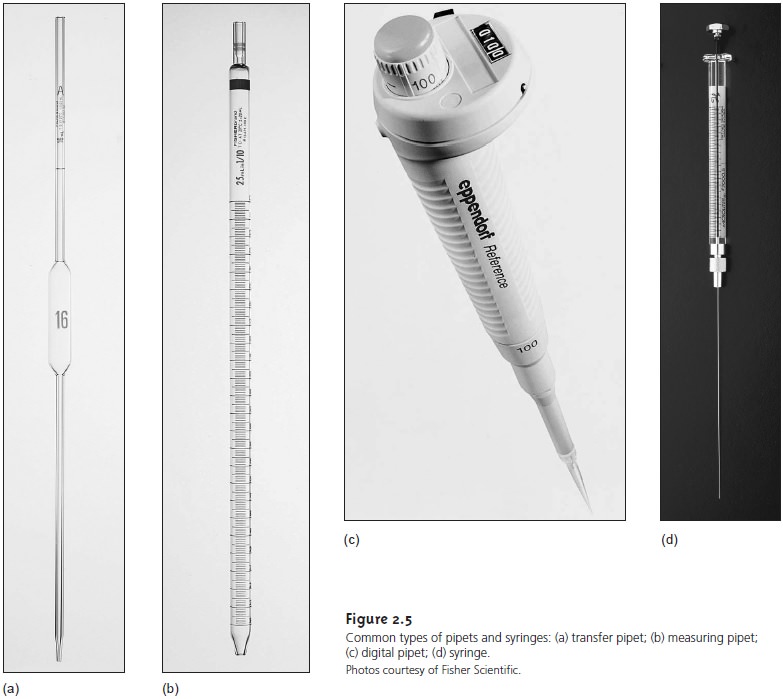

A pipet is used to deliver a specified volume of solution. Several different styles of pipets are available (Figure 2.5). Transfer pipets provide the most accurate means for delivering a known volume of solution; their volume error is similar to that from an equivalent volumetric flask. A 250-mL transfer pipet, for instance, will deliver 250.0 mL. To fill a transfer pipet, suction from a rubber bulb is used to pull the liquid up past the calibration mark (never use your mouth to suck a solu- tion into a pipet). After replacing the bulb with your finger, the liquid’s level is ad- justed to the calibration mark, and the outside of the pipet is wiped dry. The pipet’s contents are allowed to drain into the receiving container with the tip of the pipet touching the container walls. A small portion of the liquid remains in the pipet’s tip and should not be blown out. Measuring pipets are used to deliver vari- able volumes, but with less accuracy than transfer pipets. With some measuring pipets, delivery of the calibrated volume requires that any solution remaining in the tip be blown out. Digital pipets and syringes can be used to deliver volumes as small as a microliter.

Three important precautions are needed when working with pipets and

volumetric flasks. First,

the volume delivered by a pipet

or contained by a volu- metric flask assumes that the glassware

is clean. Dirt and grease on the inner glass surface

prevents liquids from draining evenly,

leaving droplets of the liquid

on the container’s walls. For a pipet this means that the delivered

volume is less than the calibrated volume, whereas drops of liquid above the calibration

mark mean that a volumetric flask contains more than its calibrated volume.

Commercially available cleaning solutions can be used to clean

pipets and volu- metric flasks.

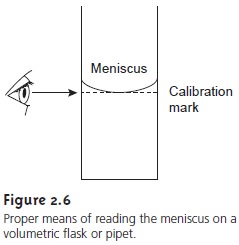

Second, when filling

a pipet or volumetric flask,

set the liquid’s

level exactly at the calibration mark. The liquid’s

top surface is curved into a meniscus, the

bottom of which should be exactly

even with the glassware’s calibration mark (Figure 2.6).

The meniscus should

be adjusted with the calibration mark at eye level to avoid parallax

errors. If your eye level is above the calibration mark the pipet

or volumetric flask will be overfilled. The pipet or volumetric flask will be underfilled if your eye level is below the calibration mark.

Finally, before using a pipet or volumetric flask you should rinse it with several small portions of the solution whose volume is being measured.

This ensures that any

residual liquid remaining in the pipet

or volumetric flask

is removed.

Equipment for Drying Samples

Many materials need to be dried prior

to their analysis

to remove residual

moisture. Depending on the material, heating

to a temperature of 110–140

°C is usually suffi- cient. Other

materials need to be heated

to much higher

temperatures to initiate thermal decomposition. Both processes can be accomplished using a laboratory oven capable of providing the required temperature.

Commercial laboratory ovens

(Figure 2.7) are

used when the

maximum de- sired temperature is 160–325 °C (depending on the model).

Some ovens include

the ability to circulate

heated air, allowing

for a more efficient removal

of moisture and shorter drying times. Other

ovens provide a tight seal for the door, allowing

the oven to be evacuated. In some situations a conventional laboratory oven can be re-

placed with a microwave oven.

Higher temperatures, up to 1700°

C, can be achieved

using a muffle furnace (Figure

2.8).

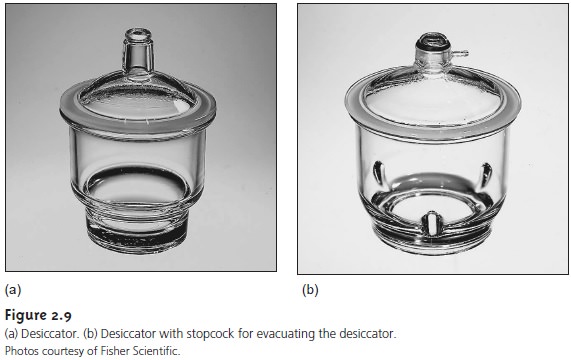

After drying or decomposing a sample, it should be cooled to room tempera- ture in a desiccator to avoid the readsorption of moisture. A desiccator (Figure 2.9) is a closed container that isolates the sample from the atmosphere. A drying agent, called a desiccant, is placed in the bottom of the container. Typical desiccants in- clude calcium chloride and silica gel. A perforated plate sits above the desiccant, providing a shelf for storing samples. Some desiccators are equipped with stopcocks that allow them to be evacuated.

Related Topics