Chapter: civil : Applied Hydraulic Engineering: Uniform Flow

Applied Hydraulic Engineering: Uniform Flow - Fundamental equations

Fundamental equations

The

equations which describe the flow of fluid are derived from three fundamental

laws of physics:

1. Conservation of matter (or mass)

2. Conservation of energy

3. Conservation of

momentum

Although

first developed for solid bodies they are equally applicable to fluids. Brief

descriptions of the concepts are given below.

Conservation

of matter

This says

that matter can

not be created nor destroyed,

but it may

be converted (e.g. by a chemical

process.) In fluid mechanics we do not consider chemical activity so the law

reduces to one of conservation of mass.

Conservation of energy

This says that energy

can not be created nor destroyed, but may be converted form one type to another

(e.g. potential may be converted to kinetic energy). When engineers talk about

energy "losses" they are referring to energy converted from

mechanical (potential or kinetic) to some other form such as heat. A friction

loss, for example, is a conversion of mechanical energy to heat. The basic

equations can be obtained from the First Law of Thermodynamics but a simplified

derivation will be given below.

Conservation of momentum

The law of conservation

of momentum says that a moving body cannot gain or lose momentum unless acted

upon by an external force. This is a statement of Newton's Second Law of

Motion: Force = rate of change of momentum

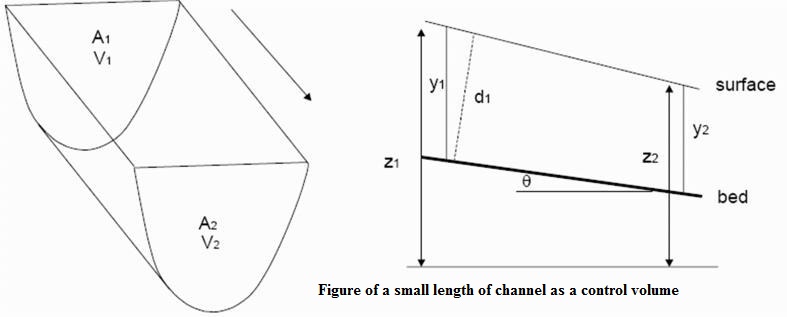

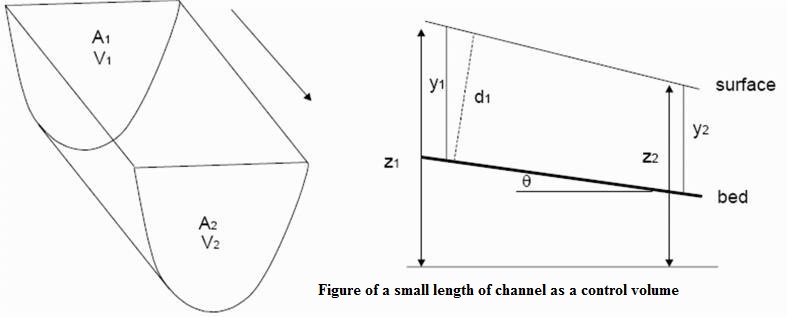

In solid mechanics

these laws may be applied to an object which is has a fixed shape and is

clearly defined. In fluid mechanics the object is not clearly defined and as it

may change shape constantly. To get over this we use the idea of control

volumes. These are imaginary volumes of fluid within the body of the fluid. To

derive the basic equation the above conservation laws are applied by

considering the forces applied to the edges of a control volume within the

fluid.

The Continuity Equation (conservation of

mass)

For any control volume

during the small time interval ?t the principle of conservation of mass

implies that the mass of flow entering the control volume minus the mass of

flow leaving the control volume equals the change of mass within the control

volume.If the flow is steady and the fluid incompressible the mass entering is

equal to the mass leaving, so there is no change of mass within the control

volume.

So

for the time interval ?t : Mass flow entering = mass flow leaving

Considering

the control volume above which is a short length of open channel of arbitrary

cross- Section then, if ? is the fluid density and Q is the volume flow

rate then section then, if mass flow rate is ? Q and the continuity

equation for steady incompressible flow can be written

pQentering

= pQleaving

As,

Q, the volume flow rate is the product of the area and the mean velocity

then at the upstream face (face 1) where the mean velocity is u and the

cross-sectional area is A1 then:

Qentering

= u1A1

Similarly

at the downstream face, face 2, where mean velocity is u2 and the

cross-sectional area is A2 then:

Qleaving=

u2A2

Therefore

the continuity equation can be written as

u1A1

= u2A2

The

Energy equation (conservation of energy):

Consider the forms of energy

available for the above control volume. If the fluid moves from the upstream

face 1, to the downstream face 2 in time d t over the length L.

The work

done in moving the fluid through face 1 during this time is

Where p1 is pressure at face 1

Work

done = p1A1L

The mass entering through face 1 is

Mass

entering = p1A1L

Therefore

the kinetic energy of the system is:

KE

= ½ mu2 = ½ p1A1Lu12

If z1

is the height of the centroid of face 1, then the potential energy of the fluid

entering the control volume is :

PE

= mgz = p1A1Lgz1

The total

energy entering the control volume is the sum of the work done, the potential

and the kinetic energy:

Total

energy = p1A1L + ½ p1A1Lu12

+ p1A1Lgz1

We can

write this in terms of energy per unit weight. As the weight of water entering

the control volume is ?1 A1 L g then just

divide by this to get the total energy per unit weight:

Total

energy per unit weight = p1/p1g + u12 + z1

At the

exit to the control volume, face 2, similar considerations deduce

Total

energy per unit weight = p2/p2g + u22 + z2

If no

energy is supplied to the control volume from between the inlet and the outlet

then energy leaving = energy entering and if the in compressible

p1/p1g +

u12 + z1 + p2/p2g + u22 + z2

= H = constant

This is

the Bernoulli equation.

Note:

1. In the

derivation of the Bernoulli equation it was assumed that no energy is lost in

the control volume - i.e. the fluid is frictionless. To apply to non

frictionless situations some energy loss term must be included.

The

dimensions of each term in equation 1.2 has the dimensions of length ( units of

meters). For this reason each term is often regarded as a "head" and

given the names

P/pg=pressure

head

U2/2g

= velocity head

Z=velocity

or potential head

3. Although above we derived the Bernoulli equation between

two sections it should strictly speaking be applied along a stream line as the

velocity will differ from the top to the bottom of the section. However in

engineering practise it is possible to apply the Bernoulli equation with out

reference to the particular streamline

The

momentum equation (momentum principle)

Again

consider the control volume above during the time ?t

Momentum entering = p ?Q1?tu1

Momentum entering = p ?Q2?tu2

By the

continuity principle : = d Q1 = dQ

2 = dQ

And by

Newton's second law Force = rate of change of momentum

It is

more convenient to write the force on a control volume in each of the three, x,

y and z direction e.g. in the x-direction

Integration

over a volume gives the total force in the x-direction as

Fx = pQ(V2x

- V1x)

As long

as velocity V is uniform over the whole

cross-section.

This is

the momentum equation for steady flow for a region of uniform velocity.

Energy and Momentum coefficients

In deriving the above momentum and energy

(Bernoulli) equations it was noted that the velocity must be constant (equal to

V) over the whole cross-section or constant along a stream-line.

Clearly

this will not occur in practice. Fortunately both these equation may still be

used even for situations of quite non-uniform velocity distribution over a

section. This is possible by the introduction of coefficients of energy and

momentum, a and ß respectively.

where V

is the mean velocity.

And the

Bernoulli equation can be rewritten in terms of this mean velocity:

P/pg + aV2/2g

+ z = constant

And the momentum equation becomes:

Fx = pQB(V2x

- V1x)

The values of ? and ß

must be derived from the velocity distributions across a cross-section. They

will always be greater than 1, but only by a small amount consequently they can

often be confidently omitted - but not always and their

existence should always be remembered.

For

turbulent flow in regular channel a does not usually go above 1.15 and ß will

normally be below 1.05. We will see an example below where their inclusion is

necessary to obtain accurate results.

Related Topics