Chapter: Modern Analytical Chemistry: Evaluating Analytical Data

Analytical Data: Characterizing Experimental Errors

Characterizing Experimental Errors

Realizing that our data for the mass of a penny can be characterized by a measure

of central tendency and a measure

of spread suggests

two questions. First,

does our measure of central tendency

agree with the true, or expected value?

Second, why are our

data scattered around

the central value?

Errors associated with

central tendency reflect the accuracy of the analysis, but the precision of the analysis

is determined by those

errors associated with the spread.

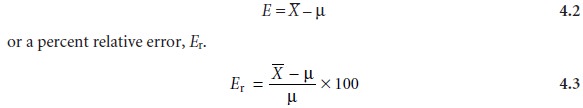

Accuracy

Although the mean is used as the measure of central tendency

in equations 4.2 and

4.3, the median could also be used.

Errors affecting the

accuracy of an analysis are

called determinate and

are char- acterized by a systematic deviation from the

true value; that

is, all the

individual measurements are either too large or too small. A positive determinate error results in a central value

that is larger

than the true

value, and a negative determinate error leads to a central value that is smaller than the true value. Both positive and nega-

tive determinate errors

may affect the

result of an analysis, with

their cumulative ef- fect leading to a net positive or negative determinate error. It is possible, although not likely, that positive and negative determinate errors may be equal, resulting in a central value with no net determinate error.

Determinate errors may be divided into four categories: sampling errors,

method errors, measurement errors, and personal

errors.

Sampling Errors

We introduce determinate sampling errors

when our sampling strategy fails to provide

a representative sample.

This is especially important when sampling heterogeneous materials. For example, determining the environmental

quality of a lake by sampling a single location

near a point source of pollution, such as

an outlet for industrial effluent, gives misleading results.

In determining the mass

of a U.S. penny, the strategy for selecting pennies

must ensure that pennies from other countries are not

inadvertently included in the sample.

Method Errors

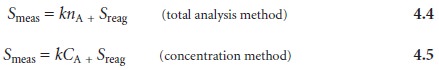

Determinate method

errors are introduced when assumptions about the relationship between

the signal and the analyte

are invalid. In terms of the

general relationships between

the measured signal

and the amount

of analyte

method errors exist

when the sensitivity, k, and the signal

due to the reagent blank, Sreag, are incorrectly determined. For example,

methods in which

Smeas is the mass of

a precipitate containing the analyte

(gravimetric method) assume that the sensitiv-

ity is defined by a pure precipitate of known stoichiometry. When this assumption fails, a determinate error

will exist. Method

errors involving sensitivity are mini- mized by standardizing the method, whereas

method errors due to interferents

present in reagents are minimized by using a proper reagent

blank. Method errors due to interferents in the sample cannot be minimized by a reagent

blank. Instead, such interferents must be sepa- rated from the analyte

or their concentrations determined independently.

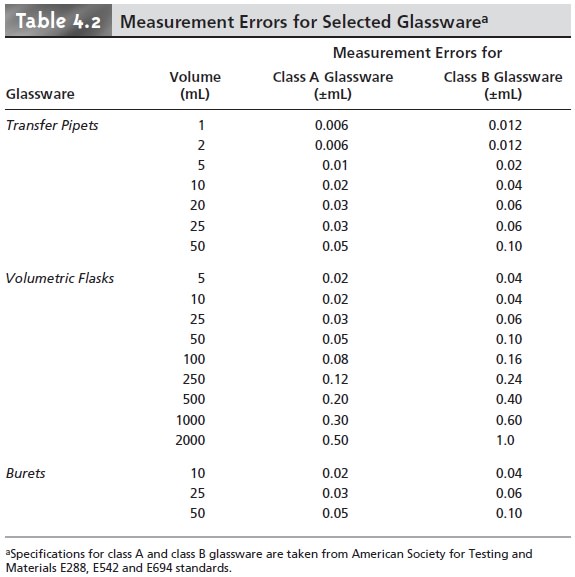

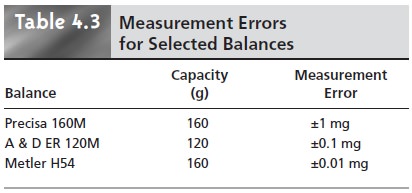

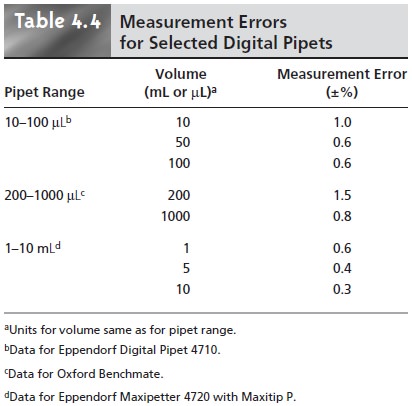

Measurement Errors

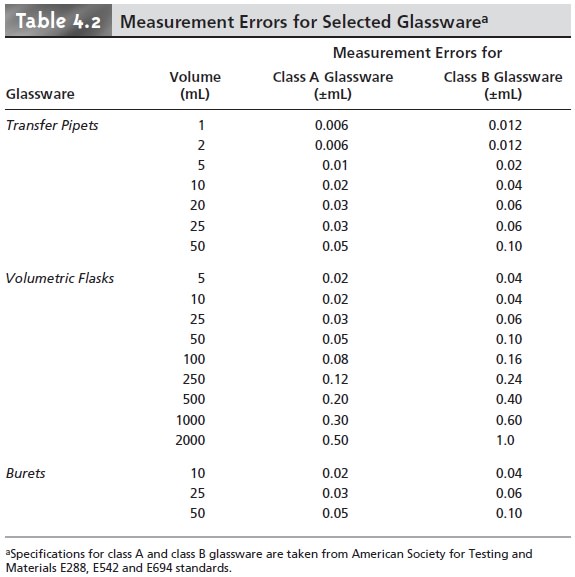

Analytical instruments and equipment, such as glassware and balances, are usually

supplied by the manufacturer with a statement of the item’s maximum measurement error, or tolerance.

For example, a 25-mL volumetric flask might have a maximum

error of ±0.03

mL, meaning that the actual

volume contained by the flask lies within the range of 24.97–25.03 mL. Although expressed as a range, the

error is determinate; thus, the flask’s

true volume is a fixed

value within the stated

range. A summary

of typical measurement errors for a variety of analytical equipment is given

in Tables 4.2–4.4.

Volumetric glassware is categorized by class. Class

A glassware is manufactured

to comply with tolerances specified by agencies such as the National Institute of Standards and Technology. Tolerance levels for class A glassware are small enough that such glassware normally

can be used without calibration. The tolerance levels for class B glassware are usually twice

those for class

A glassware. Other

types of vol- umetric glassware, such as beakers

and graduated cylinders, are unsuitable for

accu- rately measuring volumes.

Determinate measurement errors can be minimized by calibration. A pipet can be

calibrated, for example,

by determining the mass of water that it delivers

and using the density

of water to calculate the actual volume

delivered by the pipet. Al- though glassware and instrumentation can be calibrated, it is never

safe to assume that the calibration will remain unchanged during an analysis. Many instruments, in particular, drift out of calibration over time. This complication can be minimized by frequent recalibration.

Personal Errors

Finally, analytical work is always

subject to a variety of personal errors, which can include

the ability to see a change in the color of an indicator

used to signal the end point of a titration; biases, such as consistently overestimat- ing or underestimating the value on an instrument’s readout scale; failing

to cali- brate glassware and

instrumentation; and misinterpreting procedural directions. Personal errors

can be minimized with proper

care.

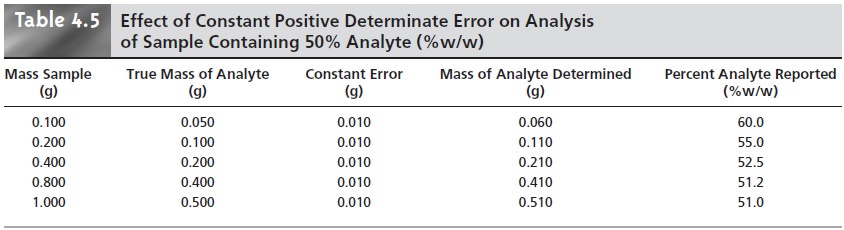

Identifying Determinate Errors

Determinate

errors can be difficult to detect.

Without knowing the true value for an analysis, the usual situation

in any analysis with meaning, there

is no accepted value with which the experimental result

can be compared. Nevertheless, a few strategies can be used to discover

the presence of a

determinate error.

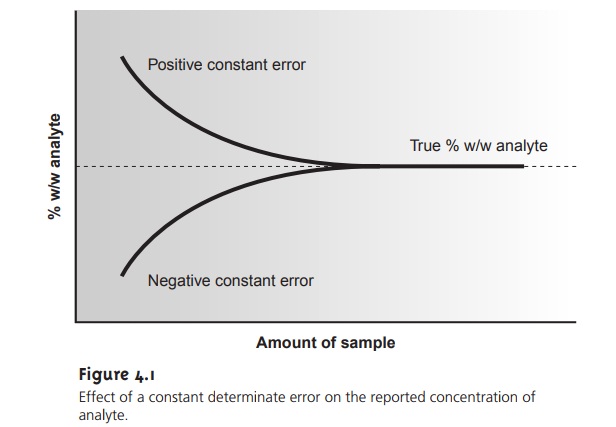

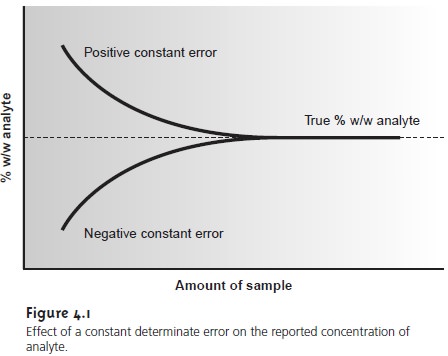

Some determinate errors can be detected

experimentally by analyzing several samples of different size. The magnitude of a constant determinate error is the same for all samples

and, therefore, is more significant when analyzing smaller

sam- ples. The presence

of a constant determinate error can be detected by running sev- eral

analyses using different amounts of sample,

and looking for a systematic change in the property being measured. For example, consider a

quantitative analysis in which we separate the analyte from

its matrix and

determine the analyte’s mass. Let’s assume that the sample

is 50.0% w/w analyte; thus,

if we analyze a 0.100-g sample, the analyte’s true mass is 0.050 g. The first

two columns of Table 4.5 give

the true mass of analyte

for several additional samples. If the analysis has a positive constant determinate error of 0.010 g, then the experimentally determined mass for

any sample will

always be 0.010

g, larger than

its true mass

(column four of Table

4.5). The analyte’s reported weight

percent, which is shown in the last column of Table

4.5, becomes larger

when we analyze

smaller samples. A graph of % w/w

ana- lyte versus amount of sample shows a distinct upward trend for small amounts

of sample (Figure 4.1). A smaller

concentration of analyte

is obtained when analyzing

smaller samples in the presence of a constant negative determinate error.

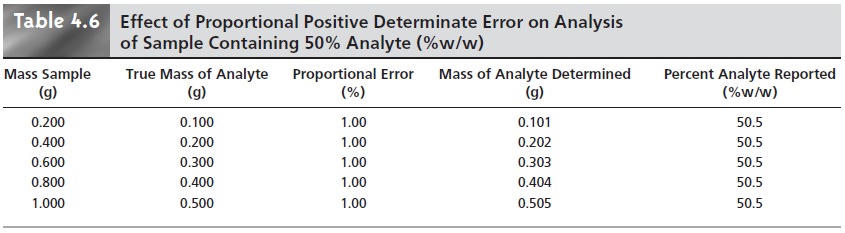

A proportional determinate error, in

which the error’s

magnitude depends on the

amount of sample,

is more difficult to detect since

the result of an analysis

is in- dependent of the amount of sample.

Table 4.6 outlines

an example showing

the ef- fect of a positive proportional error of 1.0% on the analysis of a sample

that is 50.0% w/w in analyte.

In terms of equations 4.4 and 4.5, the reagent

blank, Sreag, is an example

of a constant determinate error,

and the sensitivity, k, may be affected by proportional errors.

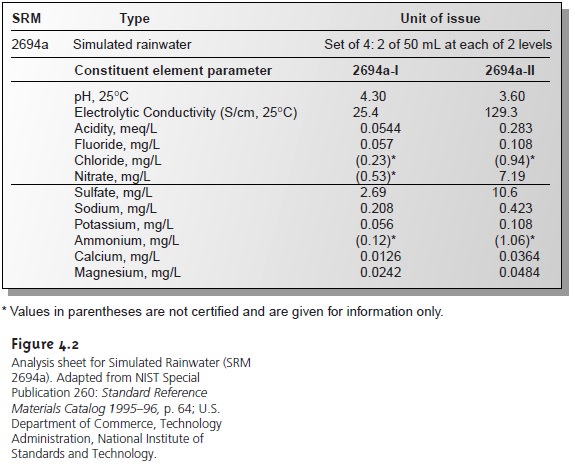

Potential determinate errors

also can be identified by analyzing a standard sam- ple

containing a known

amount of analyte

in a matrix similar to that of the samples being analyzed. Standard samples

are available from

a variety of sources, such

as the National Institute of Standards and Technology (where

they are called

standard reference materials) or the American

Society for Testing

and Materials. For exam-

ple, Figure 4.2 shows an analysis sheet

for a typical reference material. Alternatively, the sample can

be analyzed by an independent

method known to give accurate

results, and the re-

sults of the two methods

can be compared. Once identified, the source

of a determinate error can be

corrected. The best

prevention against errors

affect- ing accuracy, however,

is a well-designed procedure

that identifies likely sources of determinate errors, coupled with careful laboratory work.

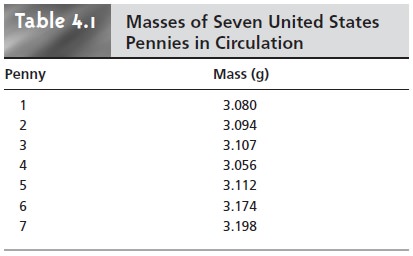

The data in Table 4.1 were obtained using a calibrated balance, certified by the manufacturer to have a tolerance of less than ±0.002 g. Suppose the Treasury Department reports that the mass of a1998 U.S. penny is approximately 2.5 g. Since the mass of every penny in Table 4.1 exceeds the re- ported mass by an amount significantly greater than the balance’s tolerance, we can safely conclude that the error in this analysis is not due to equip- ment error.

Precision

Precision is a measure of the spread

of data about

a central value

and may be ex-

pressed as the range, the standard deviation, or the variance. Precision is commonly divided into two categories:

repeatability and reproducibility. Repeatability

is the precision obtained when all measurements are made by the same analyst during

a single period of laboratory work,

using the same solutions and equipment. Repro-

ducibility, on the

other hand, is the precision obtained under any

other set of con-

ditions, including that between analysts, or between laboratory sessions for a single

analyst. Since reproducibility includes additional sources

of variability, the repro-

ducibility of an analysis can

be no better than its

repeatability.

Errors affecting the distribution of measurements around a central

value are called indeterminate

and are characterized by a random variation in both magni- tude and direction. Indeterminate errors

need not affect

the accuracy of an analy- sis. Since indeterminate errors

are randomly scattered around a central

value, posi- tive and

negative errors tend

to cancel, provided that enough measurements are made. In such situations the mean or median is largely unaffected by the precision of the analysis.

Sources of Indeterminate Error

Indeterminate errors can be traced

to several sources, including the collection of samples, the manipulation of

samples during the analysis, and the making of measurements.

When collecting a sample, for instance, only a small

portion of the available

material is taken, increasing the likelihood that small-scale inhomogeneities in the sample will affect the repeatability of the analysis. Individual pennies, for example,

are expected to show variation

from several sources,

including the manufacturing process, and the loss of small amounts of metal or the addition

of dirt during circu- lation. These

variations are sources

of indeterminate error

associated with the sam-

pling process.

During the analysis

numerous opportunities arise

for random variations in the way individual samples are treated.

In determining the mass of a penny,

for exam- ple, each penny should

be handled in the same manner. Cleaning

some pennies but not

cleaning others introduces an indeterminate error.

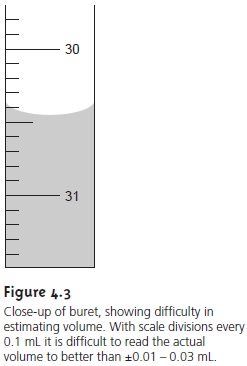

Finally, any measuring device

is subject to an indeterminate error in reading

its scale, with the last digit

always being an estimate subject

to random fluctuations, or background noise. For example, a buret with scale divisions every 0.1 mL has an in-

herent indeterminate error

of ±0.01 – 0.03 mL when estimating the volume to the

hundredth of a milliliter (Figure

4.3). Background noise

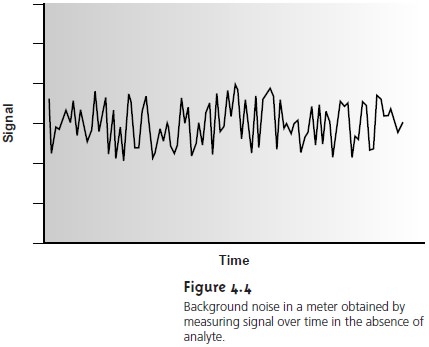

in an electrical meter (Figure 4.4) can be evaluated by recording the signal without

analyte and observing

the fluctuations in the signal over time.

Evaluating Indeterminate Error

Although it is impossible to eliminate indetermi- nate error, its effect can be minimized if the sources

and relative magnitudes of the indeterminate

error are known. Indeterminate errors may be estimated by an ap- propriate measure of spread.

Typically, a standard deviation is used, although in some cases

estimated values are

used. The contribution from analytical instruments and equipment are easily

measured or estimated. Inde- terminate errors

introduced by the

analyst, such as in-

consistencies in the treatment of individual samples, are more difficult to estimate.

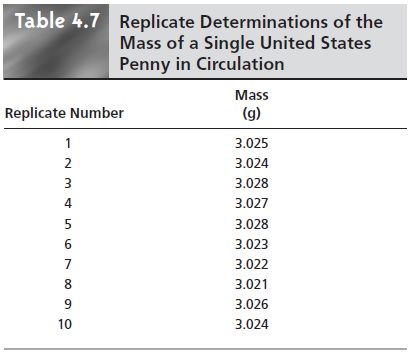

To evaluate the effect of indeterminate error

on the data in Table 4.1,

ten replicate determinations of the mass of a single penny were made, with results shown in Table 4.7. The standard

deviation for the data in Table 4.1 is 0.051,

and it is 0.0024 for the data in Table 4.7. The significantly better precision when determining the mass of a single penny sug- gests

that the precision of this analysis

is not limited by the balance

used to measure

mass, but is due to a

significant variability in the masses of individual

pennies.

Error and Uncertainty

Analytical chemists make a distinction between error and uncertainty.3 Error is the difference between a single measurement or result and its true value. In other words, error is a measure of bias. As discussed earlier,

error can be divided into de-

terminate and indeterminate sources. Although we can correct

for determinate error, the

indeterminate portion of the error

remains. Statistical significance testing, provides a way to determine whether a bias resulting from determinate error

might be present.

Uncertainty expresses the

range of possible values that a measurement or result

might reasonably be expected to have. Note that this definition of uncertainty is not

the same as that for precision. The precision of an analysis, whether reported as a

range or a standard deviation, is calculated from

experimental data and

provides an estimation of indeterminate error

affecting measurements. Uncertainty accounts for all errors,

both determinate and

indeterminate, that might

affect our result.

Al- though we always

try to correct

determinate errors, the

correction itself is subject to random effects or indeterminate errors.

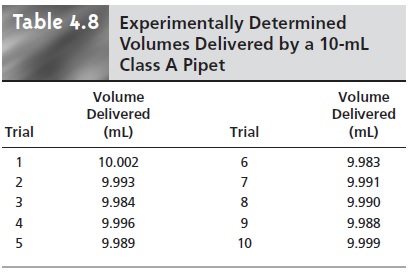

To illustrate the difference between

precision and un- certainty, consider the use of a class A 10-mL pipet for de- livering solutions. A pipet’s

uncertainty is the range of volumes in which its true volume

is expected to lie. Sup- pose you purchase a 10-mL class

A pipet from

a labora- tory supply

company and use it without

calibration. The pipet’s tolerance value of ±0.02

mL (see Table

4.2) repre- sents your uncertainty since your best estimate of its vol- ume

is 10.00 mL ±0.02 mL.

Precision is determined ex- perimentally by using the pipet several times, measuring

the

volume of solution delivered each time. Table 4.8 shows results

for ten such trials that have a mean of 9.992

mL and a standard deviation of 0.006. This standard devi- ation represents the precision

with which we expect to be

able to deliver a given

solution using any class A 10-mL

pipet. In this case the uncertainty in using a pipet is worse

than its precision. Interestingly, the data in Table 4.8 allow us to calibrate this specific pipet’s

delivery volume as 9.992 mL.

If we use this vol- ume as a better estimate of this pipet’s

true volume, then the uncertainty is ±0.006. As expected, calibrating the pipet

allows us to lower its uncertainty.

Related Topics