Chapter: Civil : Railway Airport Harbour Engineering : Railway Engineering : Equipment at Railway Stations

A turntable in Railway Stations

Turntable

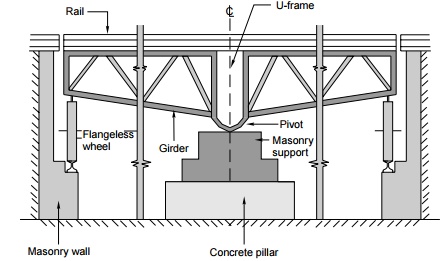

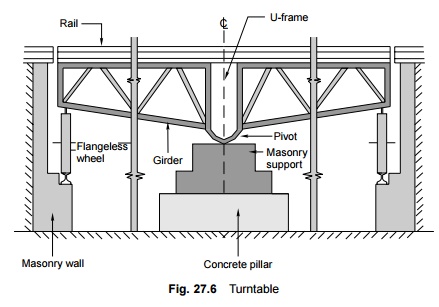

A turntable (Fig. 27.6) is a

device used for changing the direction of a locomotive. It is normally provided

at terminal stations, locomotive yards, and marshalling yards.

1 Main Features

A turntable basically consists of

a track supported on two parallel fish-bellied girders which are braced

together and supported on or suspended from a central pivot. Sets of flangeless

wheels are attached to the ends of the girders, which roll over the rails along

the circumference of the pit, called race rails. The turntable is installed in

a circular masonry pit. The girders supporting the track move around the rail

and can be fixed in the desired position with the help of locking bolts. The

bottom of the masonry pit slopes towards the centre and a sump is provided for

draining rainwater by means of a sump and drain arrangement. Two or more tracks

radiate outwards from the circular edge of the pit and are so designed that

they can be aligned and temporarily connected to the track of the turntable.

The diameter of the turntable

should be such that it can accommodate the longest engine in service on the

section. The turntables normally provided on Indian Railways are of the

following sizes:

BG: 30.5 m (100'), 22.9 m (75'), and 19.8 m (65')

MG: 19.8 m (65') and 15.75 m (50')

2 Working Details

A turntable helps in reversing the direction of an engine in

the following manner.

When the direction of an engine is to be reversed, the

turntable is made to revolve either manually or electrically on the pivot and

is brought in line with the track on which the engine is standing. This

position is then locked with the help of locking bolts.

2. The

engine is then brought on the track of the turntable and the locking bolts are

removed.

3. The

turntable is rotated again till the turntable track aligns with the track where

the engine is required to go.

4. This

position is locked with the help of locking bolts and the engine is shunted and

brought on the required track.

3 Maintenance

It is essential that the

turntable be properly maintained for it to work efficiently. The following

aspects of turntable maintenance require special attention.

(a) The

central pivot and other parts should be oiled and greased to ensure that they

work smoothly.

(b) The level

of the race rail should be perfect and its alignment should be correct.

(c) The

various parts of the turntable should be painted periodically to avoid the

corrosion and rusting of its steel parts.

As steam locomotives have been

phased out on Indian Railways, all equipment connected with steam locomotives

such as ashpits, ash pans, turntables, and water columns are now of historical

importance only.

Related Topics