Chapter: Civil : Railway Airport Harbour Engineering : Railway Engineering : Equipment at Railway Stations

Equipment at Railway Stations

Equipment

at Railway Stations

Introduction

A lot of equipment is required at

railway stations and yards for the efficient working of the railway system.

This equipment serves the following purposes.

(a) Providing

facilities for the convenience of passengers-platforms, foot over bridges, and

subways.

(b) Receipt

and dispatch of goods traffic-cranes, weigh bridges, loading gauges, and end

loading ramps.

(c) Equipment

for locomotives and coaches-locomotive sheds, examination pits, ashpits, water

columns, turntables, and triangles.

(d) Isolation

of running lines-and derailing switch, scotch block, sand humps, buffer stops,

and fouling marks.

The

details of some of the important railway equipment are given in this chapter.

1 Platforms

The following types of platforms are provided on Indian

Railways.

Passenger platforms

These are provided to facilitate

the movement of passengers and to help them entrain and detrain. Passenger

platforms can be of three types, namely, rail-level platforms, low-level

platforms, and high-level platforms. These have been discussed in detail in

Chapter 26.

Goods platforms

These platforms are provided for

the loading and unloading of goods and parcels onto and from wagons. The essential

features of these goods platforms are the following.

(a) A goods

platform is normally surfaced with bituminous carpet or concrete. In the case

of light traffic, moorum or water-bound macadam can also be used.

(b) The

height of a goods platform is l.07 m for BG, 0.69 m for MG, and 0.61 m for NG

lines. The height of the platform is measured from the rail level and is such

that the platform surface is flush with the floor of the wagon for the easy

loading and unloading of goods.

(c) Adequate

storage accommodation is provided on goods platforms for the storage of goods

and parcels.

(d) Mobile

cranes or fixed overhead gantry cranes are provided for the handling of bulky

and heavy parcels.

2 Foot Over Bridges and Subways

Foot over bridges are provided

for the movement of passengers and light baggage from one platform to another.

Bulky or heavy goods are taken from one platform to another by means of a

handcarts, which are carried across the tracks near the end of the platform in

order to reach the requisite platform. Some stations are also provided with

subways for the movement of the passengers and goods between platforms.

3 Cranes

Cranes are normally provided in

goods sheds to load and unload bulky or heavy material such as heavy machines

and logs from wagons. These are normally of three types.

Fixed jib crane This

crane is fixed at a convenient location on the goods platform for the

purpose of loading and unloading bulky and heavy goods from wagons.

Mobile crane This

crane is mounted on a wagon or a truck and can be moved anywhere on the

platform as per requirement to load or unload bulky parcels.

Overhead gantry cranes It

consists of two horizontal girders or beams supported on a number of

vertical posts. A travelling platform is fixed in between the two girders,

which is fitted with equipment for hoisting goods and is capable of moving to

and fro on the girders. Wagons or road vehicles are brought under the gantry

for loading and unloading materials.

4 Weigh Bridge

A weigh bridge is used to weigh a

loaded wagon so as to get an idea of the weight of its contents. It is

basically a small length of track on a platform that is supported on beams. The

beams are located in a pit under the track and rest on knife edges attached to

levers. When a wagon is placed on the weigh bridge, its weight is indicated by

a pointer on a graduated disc located in an adjoining structure. A weigh bridge

is normally provided on a siding and not on a through track.

5 Loading Gauge

The loading gauge is the gauge or

profile up to which a vehicle can be loaded in order to maintain a minimum

clearance between the loaded top of the wagon and the underside of a structure

such as a bridge, tunnel, or signal post. The dimensions of the load of the wagon

are kept within the fixed limits by erecting a loading gauge across the track

in the shape of a steel frame, which causes an obstruction if the wagon is

loaded to an extent that exceeds the loading gauge (see in old pages).

Loaded wagons whose dimensions

exceed the normal permissible loads are known as oversized dimensioned

consignments (ODCs). ODC parcels can also be sanctioned up to a certain

level after taking the following precautions.

(a) Trains

carrying ODCs should move at a restricted speed, which is specified for the

purpose.

(b) Such

trains should not move at night.

(c) Train

carrying ODCs should be accompanied by a supervisor whose duty is to ensure the

safely of the train along the route.

6 End Loading Ramps

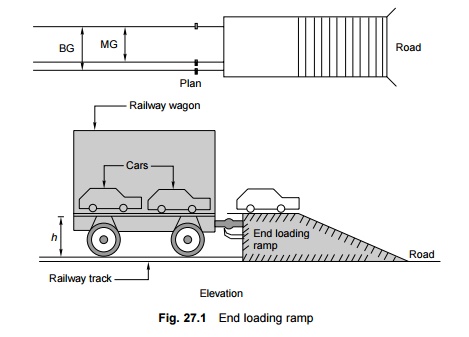

End loading ramps (Fig. 27.1) are provided to

allow the unloading of the wagons at their rear end. Such ramps are also used

for unloading cars and other mobile vehicles. An end loading ramp has the

following essential features.

(a) It has a

dead end siding with a buffer stop and a platform with a ramp.

(b) The

platform is at a height of 1.3 m for BG and 0.86 m for MG lines.

(c) A small

gap is maintained between the buffer stop and the ramp platform to minimize the

damage to the platform. This gap is covered by the hinged plates of the wagon

while it is being unloaded.

7 Locomotive Sheds

Locomotive or running sheds are

meant for the maintenance and servicing of locomotives. The location and design

of a locomotive shed depends on the volume and pattern of traffic, the layout

of the terminal station and the marshalling yard, and other allied factors.

Locomotive sheds are normally spaced at about 250 to 300 km apart in order to

avoid the idle movement of locomotives and crew. Locomotive sheds are basically

of two types.

Homing sheds These are

provided to house locomotives and attend to their maintenance and

servicing. Equal stress is laid on the servicing and maintenance of locomotives

in these sheds. These sheds are normally designed to house about 80 to 100

locomotives.

Turn round sheds These are

provided for servicing locomotives and bringing them back to the homing

sheds. They may also be provided for attending to certain minor repairs. These

sheds are normally designed to hold about 30 to 50 locomotives.

8 Ashpits

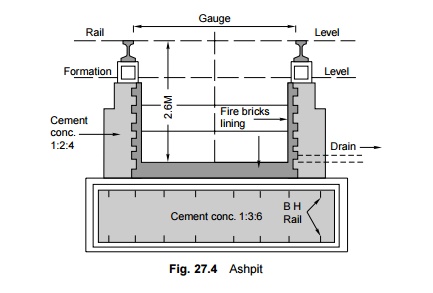

Ashpits (also called de-ashing Pits) (Fig. 27.4)

are provided to collect the ashes falling from the locomotives. They are

rectangular in shape and of a depth of about 1 m and are lined with fire

bricks. The length of the ashpits should be adequate so that the longest

locomotive can be de-ashed on the pit. The length is normally 15.9 m (52 ft)

for BG locomotives. The ashpits are suitably sloped from the centre towards the

ends so that water can be drained effectively.

The ashpits should be cleaned as

often as possible. The ashes should first be dumped outside the pit and

subsequently removed and stored at a suitable place for further disposal. The

area around the ashpit should be paved and ample space should be provided for

the picking up and storage of cinder.

Ashpits are normally provided at

those points in the locomotive sheds where the locomotives turn for cleaning or

dropping of fire. These are also provided in big stations at places where the

locomotives collect water for de-ashing.

9 Water Columns

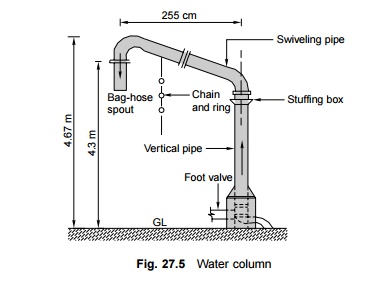

Water columns (Fig. 27.5) are

provided to supply water to the locomotives. A water column consists of a

vertical pipe with a surveilling arm of either a horizontal shape or the shape

of a swan's neck. A bay hose spout is provided at the end of the arm to enable

water to be diverted to the opening in the engine tender. A foot valve is fixed

inside the water column and water is made available from a suitably located

high service tank.

Water columns are provided in

locomotive yards as well as at various stations, where engines are required to

be watered and fuelled.

10 Turntable

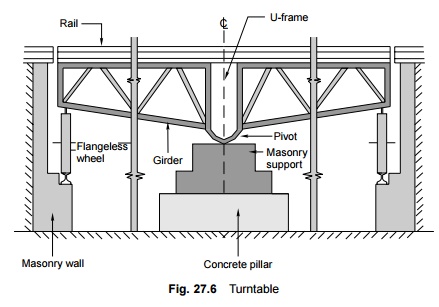

A turntable (Fig. 27.6) is a

device used for changing the direction of a locomotive. It is normally provided

at terminal stations, locomotive yards, and marshalling yards.

11 Triangles

Triangles are used for reversing

the direction of engines at locations where providing a costly turntable may

not be justified and where the available area is adequate for the provision of

a triangle. Triangles are normally provided at the terminals of short lines.

The details of a triangle are given in Chapter 15.

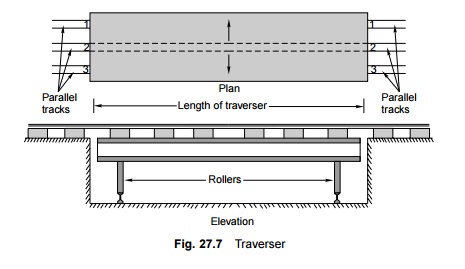

12 Traverser

This is a device for transferring

vehicles from one track to a parallel one without the use of a turnout or a

crossover. It is quite a costly arrangement and is preferred only in workshops

where space is limited and a coach or locomotive is required to be shifted from

one shop to another on a nominated line.

A traverser (Fig. 27.7) consists

of a platform with a track that is mounted on small wheels or rollers, which

can traverse to and fro and can fall in line with the track on either side of

the traverser. The following steps are involved in transferring a vehicle

standing on track 3 on the left-hand side of the traverser to track 2 on the

right-hand side.

1. The traverser

is aligned with track 3 on the left-hand side.

2. The

vehicle is then transferred to the traverser track.

3. The

traverser is then shifted so as the align it with the track on the right-hand

side.

4. The

vehicle is then transferred to track 2 on the right-hand side.

13 Carriage Washing Platforms

Terminal stations are provided

with the facility for washing carriages so that passenger bogies can be cleaned

and washed properly. This consists of two or three long sidings that can

accommodate the entire length of the rake and washing platforms that are

provided between the sidings. The salient features of these washing platforms

are the following.

(a) Washing

platforms are long platforms of a height equal to the height of the carriage

floor that are generally made of cement concrete. In the case of BG lines their

width is about 0.61 m.

(b) The

washing platform is equipped with a number of hydrants for washing the

carriages. An adequate water supply is made available to ensure that the

pressure of the water inside the hydrant is sufficient.

(c) A washing

platform is normally provided between two tracks so that two carriages can be

washed simultaneously.

(d) The

tracks are supported on masonry structures and have adequate arrangement for

the drainage of water.

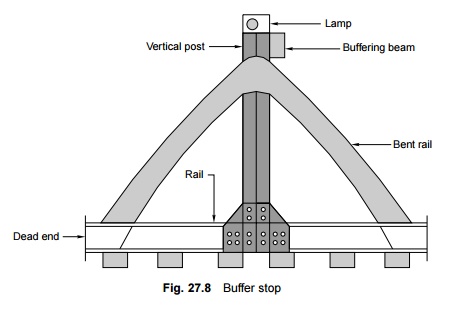

14 Buffer Stop

Buffer stops (Fig. 27.8) or 'snag

dead ends' are provided at the end of a siding to ensure that the vehicles stop

while still on the track and do not go off it. The buffer stop is a type of

barrier placed across the track which stops the vehicles from going beyond the

selected point. Its essential features are the following.

(a) The

buffer stop should be structurally strong to take the impact of a rolling

vehicle.

(b) It should

have a buffer disc with a cross-sleeper, which is normally painted red. A red

lamp should be provided at its centre for night indication.

(c) Normally

the track should be straight for some distance near the buffer stop.

(d) It should

be visible from a long distance.

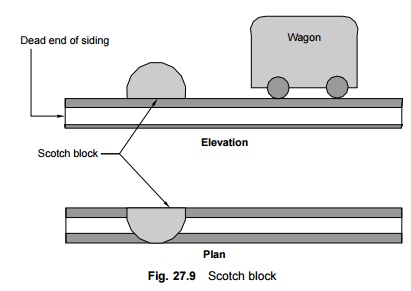

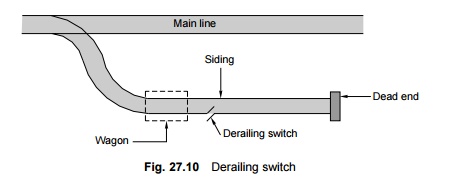

15 Scotch Block, Derailing Switch, and

Sand Hump

It is normal practice to isolate

a through running line from a siding so that a vehicle standing on the siding

does not accidentally roll onto the running line and foul the same. A scotch

block or derailing switch is provided on a siding or shunting neck to ensure

that the vehicle does not go beyond a particular point and that if this

happens, the vehicle gets derailed.

Scotch block A scotch

block (Fig. 27.9) is a wooden block placed on the rail and properly held

in its place with the help of a device to form an obstruction. Once it is

clamped in position, the scotch block does not allow a vehicle to move beyond

it.

Derailing switch A

derailing switch (Fig. 27.10) consists of a half-switch, i.e., only a

tongue rail, which in its open position faces away from the stock rail, leaving

a gap in between, and this causes a discontinuity in the track. A vehicle

cannot go beyond this point and gets automatically derailed if it does manage

to do so. The switch can be closed with the help of a lever and a vehicle can

then traverse it normally. This is also called a trap switch.

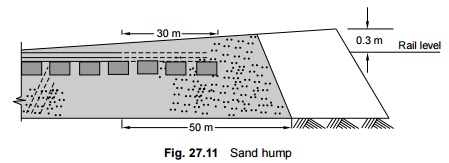

Sand hump This is

possibly the most improved method of isolating and stoping a moving

vehicle without causing much damage to it. The sand hump (Fig 27.11) is normally

provided on the loop line with the idea that in case an incoming train

overshoots when being received on the loop line, the sand hump can make it stop

while ensuring that there is least damage to it.

A sand hump consists of a mound

of sand of a specified cross section that covers the track under the end of a

dead end siding, which is laid on a rising gradient. A moving vehicle comes to

a stop because of the combined resistance of the sand hump and the rising

gradient.

16 Fouling Mark

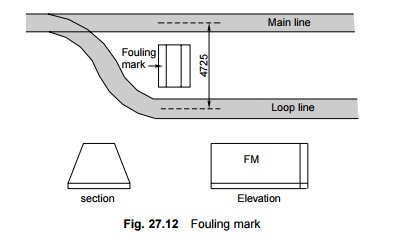

A fouling mark (Fig. 27.12) is

provided between two converging tracks at the point beyond which the

centre-to-centre distance of the track is less than the stipulated minimum

distance. This minimum distance is 4.265 m for BG and 3.66 m for MG lines. A

vehicle standing on a loop line is not stabled beyond the fouling mark,

otherwise it may have a side collision with the vehicle standing on the main

line. The salient features of a fouling mark are as follows.

(a) A fouling

mark consists of a stone or concrete block or an old wooden or steel sleeper

painted white.

(b) The

fouling mark should be visible from a distance. Therefore, it is painted white

and has the letters FM marked on it in bold using black paint.

(c) The top

of the fouling mark should be in line with the top of the ballast section.

(d) The

fouling mark should be fixed firmly on the ground at right angles to the track.

Related Topics