Chapter: Civil : Railway Airport Harbour Engineering : Railway Engineering : Equipment at Railway Stations

Ashpits or de-ashing Pits in Railway Stations

Ashpits

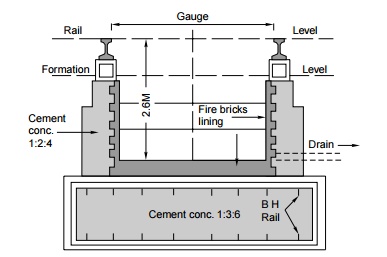

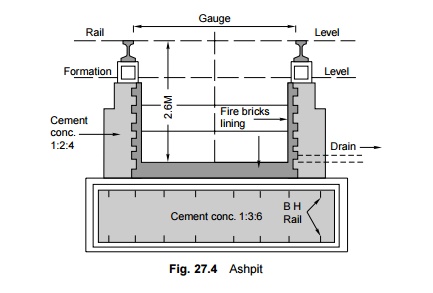

Ashpits (also called de-ashing Pits) (Fig. 27.4)

are provided to collect the ashes falling from the locomotives. They are

rectangular in shape and of a depth of about 1 m and are lined with fire

bricks. The length of the ashpits should be adequate so that the longest

locomotive can be de-ashed on the pit. The length is normally 15.9 m (52 ft)

for BG locomotives. The ashpits are suitably sloped from the centre towards the

ends so that water can be drained effectively.

The ashpits should be cleaned as

often as possible. The ashes should first be dumped outside the pit and

subsequently removed and stored at a suitable place for further disposal. The

area around the ashpit should be paved and ample space should be provided for

the picking up and storage of cinder.

Ashpits are normally provided at

those points in the locomotive sheds where the locomotives turn for cleaning or

dropping of fire. These are also provided in big stations at places where the

locomotives collect water for de-ashing.

1.Ash Pans

Ash pans are also used for the

de-ashing of locomotives. These consist of U-shaped precast reinforced concrete

units placed side by side for the retention of ashes. Ash pans are normally

provided in station yards. Though these pans have a very low capacity, they

still have the following advantages.

(a) Easy to

construct

(b) Very

economical

(c) No speed

restriction necessary on the main line when ash pans are provided

2 Examination Pits

Examination pits (also called

outgoing pits) are used both for fire de-ashing before the locomotives leave

the sheds and for outgoing engine examination and repairs. These pits should

have a minimum length of 25 m with stairs at the ends to enable the staff to go

underneath the locomotives for inspection and repair. The pit should be about 1

m deep and lined with fire bricks for about 6 m in the centre where fire

cleaning is to be carried out. A water column should be provided by the side of

each pit.

3 Drop Pits

Drop pits are provided in order

to enable the wheels of the locomotives to be removed for examination, repairs,

and renewals. These pits are normally provided at right angles to the track.

Mobile jacks are installed to enable the wheels and axles to be removed.

Related Topics