Chapter: Civil : Railway Airport Harbour Engineering : Railway Engineering : Equipment at Railway Stations

Equipment at Railway Stations: Locomotive Sheds

Locomotive Sheds

Locomotive or running sheds are

meant for the maintenance and servicing of locomotives. The location and design

of a locomotive shed depends on the volume and pattern of traffic, the layout

of the terminal station and the marshalling yard, and other allied factors.

Locomotive sheds are normally spaced at about 250 to 300 km apart in order to

avoid the idle movement of locomotives and crew. Locomotive sheds are basically

of two types.

Homing sheds These are

provided to house locomotives and attend to their maintenance and

servicing. Equal stress is laid on the servicing and maintenance of locomotives

in these sheds. These sheds are normally designed to house about 80 to 100

locomotives.

Turn round sheds These are

provided for servicing locomotives and bringing them back to the homing

sheds. They may also be provided for attending to certain minor repairs. These

sheds are normally designed to hold about 30 to 50 locomotives.

1 Layout of Locomotive Sheds

The layout of locomotive sheds is

normally of three different types, namely, round house type, rectangular type,

and mixed type.

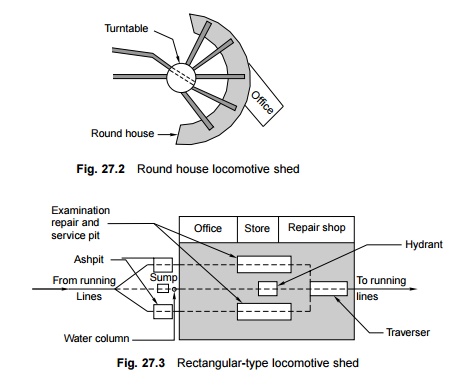

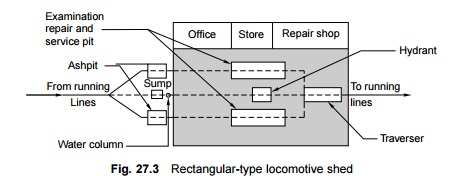

Round house locomotive shed

The round house shed (Fig. 27.2) consists of a

number of locomotive repair and stabling lines radiating from a turntable in

the centre. The shed is normally in the shape of a circle or a polygon. The

incoming engine is taken to the turntable and transferred to a particular line

for repair. The provision of a turntable eliminates the need for shunting.

The locomotive enters and leaves

from the same end and, therefore, in the event of the turntable becoming

inoperative, the movement of all the locomotives is discontinued until the

turntable is repaired. This type of shed layout is not recommended for Indian

Railways.

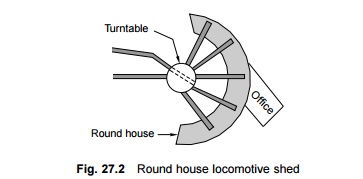

Rectangular-type locomotives shed

These sheds (Fig 27.3) are rectangular in shape

and are most commonly used on Indian Railways. A rectangular-type shed can be a

blind shed, a through shed, or a mixed-type shed. In the blind type of shed,

all the repair bays terminate at dead ends and locomotives can enter and exit

from one end only, thus leading to conflicts in the movement of the

locomotives. However, these types of sheds are cheap because they save on the

amount of space needed for tracks and turnouts at the rear end. Such

rectangular sheds can be planned for small locomotive holdings.

In a through rectangular shed,

the locomotives move from one end to the other in the correct sequence of the

operations that are to be performed for servicing. Such a shed offers

considerable scope for future expansion and tenders the maximum flexibility in

shed operations.

Mixed-type shed

A mixed-type shed has the

characteristics of both a blind and a through type. These sheds are suitable

for locations that require expansion in the near future but lack the requisite.

2 Essentials of a Well Laid Out

Locomotive Shed

A locomotives shed should satisfy the following conditions.

(a) As far as

possible, the design of the shed should allow the engines to move only in one

direction. The multidirectional movement of the engine, apart from creating

unsafe conditions, would invariably slow the engine down and cause them to be

unduly detained.

(b) The

design should be such that the time taken by the engine in passing through the

shed is reduced to the minimum.

(c) The

layout should be such that it is possible to skip one or more stages of

servicing, as all engines do not require the entire cycle of servicing.

(d) There

should be adequate stabling accommodation, both covered and open, for all

engines.

(e) There

should be adequate facilities for the servicing and repairs of engines.

(f) There

should be a separate shed for carrying out heavy repairs involving the lifting

of engines or dropping of wheels.

(g) It should

be provided with an adequate water supply for the servicing of locomotives as

well as for domestic use.

(h) There

should be provision for stores and a tool room for general maintenance and

repair work. Adequate office accommodation should also be made available for

the supervisors and the staff.

(i) The

sequence of operations normally followed in locomotive sheds is as follows:

inspection ® cooling ® turning ® fire

cleaning ® placement

® repairs ® outgoing inspection ® departure to traffic yard.

Related Topics